Yes, ceramic heaters are widely considered one of the safest portable heating options available. Their inherent design, which uses a ceramic heating element instead of glowing-hot metal coils, significantly reduces risks. Modern units are also equipped with crucial safety features that automatically prevent common hazards like overheating and tipping over.

The safety of a ceramic heater is not just a feature; it's a result of its core technology. However, its ultimate safety in your home depends on combining these built-in protections with responsible placement and use.

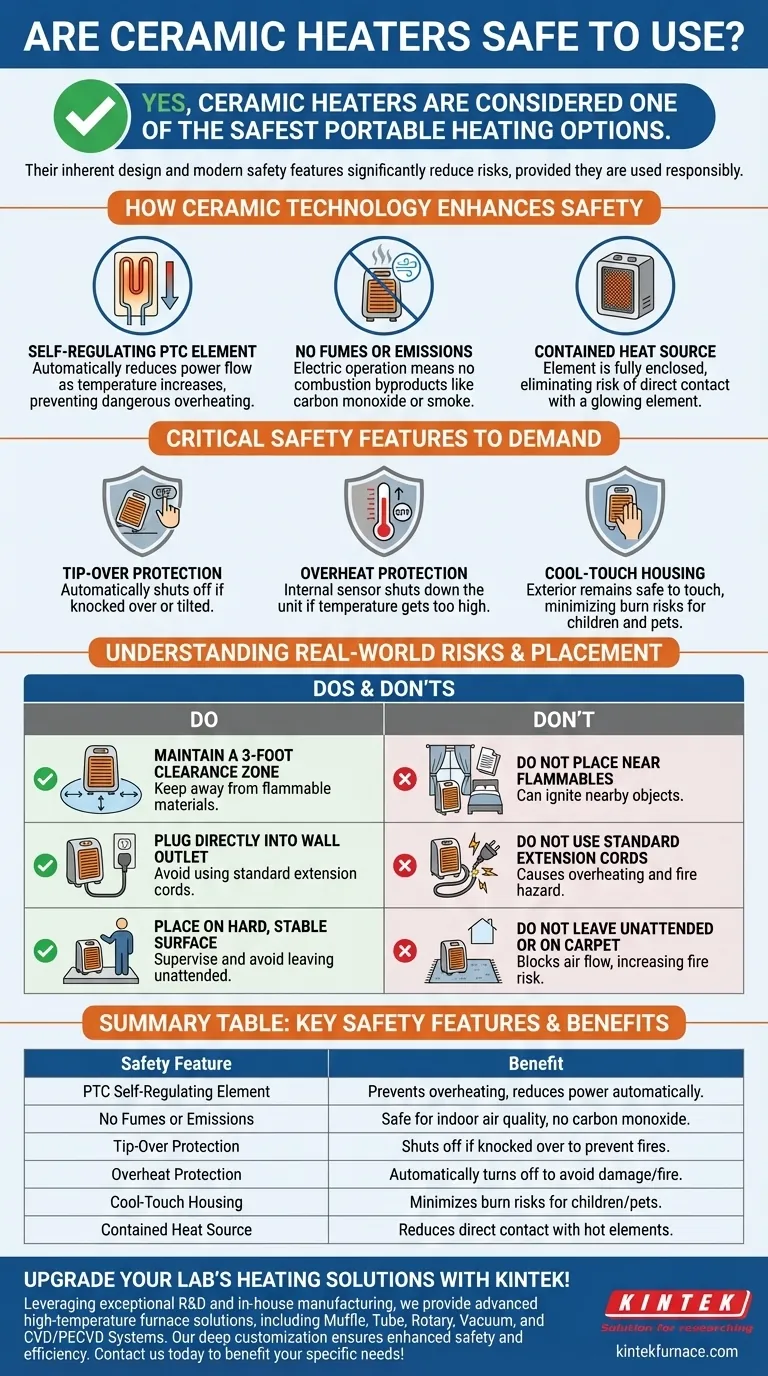

How Ceramic Technology Enhances Safety

The safety of a ceramic heater begins with its fundamental design. Unlike older technologies, its method of generating heat is inherently more stable and contained.

The Self-Regulating Ceramic Element

Ceramic heaters use a principle called Positive Temperature Coefficient (PTC). As the ceramic element heats up, its electrical resistance naturally increases.

This process automatically reduces the flow of electricity, causing the heater to self-regulate its temperature and preventing it from getting dangerously hot.

No Fumes or Emissions

Because ceramic heaters are electric, they do not burn fuel to create heat.

This means they produce no combustion byproducts like carbon monoxide, smoke, or other harmful fumes, making them safe for indoor air quality.

Contained Heat Source

The ceramic heating element is fully enclosed within the heater's casing.

This design eliminates the risk of direct contact with a glowing-hot element, drastically reducing the chance of immediate burns compared to older heaters with exposed coils.

Critical Safety Features to Demand

While the technology is sound, manufacturers add layers of protection. Never purchase a heater that lacks third-party safety certification (like from UL, ETL, or CSA) and these key features.

Tip-Over Protection

This is arguably the most critical safety feature. An internal switch automatically shuts the heater off completely if it is knocked over or tilted.

This function is essential for preventing fires if the heater is accidentally bumped by a person, pet, or object.

Overheat Protection

All reputable ceramic heaters contain an internal sensor that monitors the unit's temperature.

If the heater becomes too hot, whether from a blocked vent or a component malfunction, this sensor will automatically shut the unit down to prevent internal damage and fire risk.

Cool-Touch Housing

Many modern units are built with a plastic or composite housing that is engineered to stay cool, or at least safe to touch, even when the heater is operating at full power.

This is an invaluable feature in homes with children or pets, as it minimizes the risk of accidental contact burns.

Understanding the Real-World Risks

No heating appliance is entirely without risk. The dangers associated with ceramic heaters almost always stem from improper use, not from the technology itself.

The Hazard is Placement, Not the Heater

The single greatest fire risk is placing the heater too close to flammable materials.

Always maintain a minimum three-foot clearance zone around the front, sides, and top of the heater. Keep it away from curtains, bedding, furniture, paper, and rugs.

Never Use Standard Extension Cords

Ceramic heaters draw a significant amount of electrical current. Plugging one into a standard, light-duty extension cord can cause the cord to overheat, melt, and create a severe fire hazard.

If you must use an extension cord, ensure it is a heavy-duty appliance cord rated for the heater's wattage, and use it only temporarily. The safest method is always to plug the heater directly into a wall outlet.

Supervise and Place on a Hard Surface

Never leave a space heater running while you are asleep or have left the room.

Furthermore, always place the heater on a flat, hard, non-flammable surface like a tile or hardwood floor. Placing it on a carpet can block air intakes and create a fire risk.

Making the Right Choice for Your Space

To ensure safety, match the heater's features to your primary concern.

- If your primary focus is preventing fires: Prioritize a model with certified tip-over and overheat protection, and always maintain the 3-foot clearance zone.

- If you have children or pets: Choose a heater with a cool-touch exterior and a stable, wide base to minimize the risk of accidental burns or knock-overs.

- If your goal is worry-free operation: Look for models with an adjustable thermostat and a programmable timer to automate shut-off and prevent it from running unattended.

A modern ceramic heater, used with awareness and respect for its power, is a secure and effective way to add comfort to your environment.

Summary Table:

| Safety Feature | Benefit |

|---|---|

| PTC Self-Regulating Element | Prevents overheating by automatically reducing power |

| No Fumes or Emissions | Safe for indoor air quality with no carbon monoxide |

| Tip-Over Protection | Shuts off if knocked over to prevent fires |

| Overheat Protection | Automatically turns off to avoid internal damage |

| Cool-Touch Housing | Minimizes burn risks for children and pets |

| Contained Heat Source | Reduces direct contact with hot elements |

Upgrade your lab's heating solutions with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced safety and efficiency. Contact us today to discuss how our products can benefit your specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment