You’ve spent weeks, maybe months, perfecting your process. The materials are pristine, the procedure is meticulously documented, and your team is executing flawlessly. Yet, the parts coming out of your high-temperature furnace are a gamble. Some meet spec perfectly, while others are warped, brittle, or fail quality control. The furnace controller confidently displays the setpoint temperature—1000°C—but the inconsistent results tell a different story. You're stuck in a frustrating loop of re-runs, wasting valuable materials and time, with no clear culprit in sight.

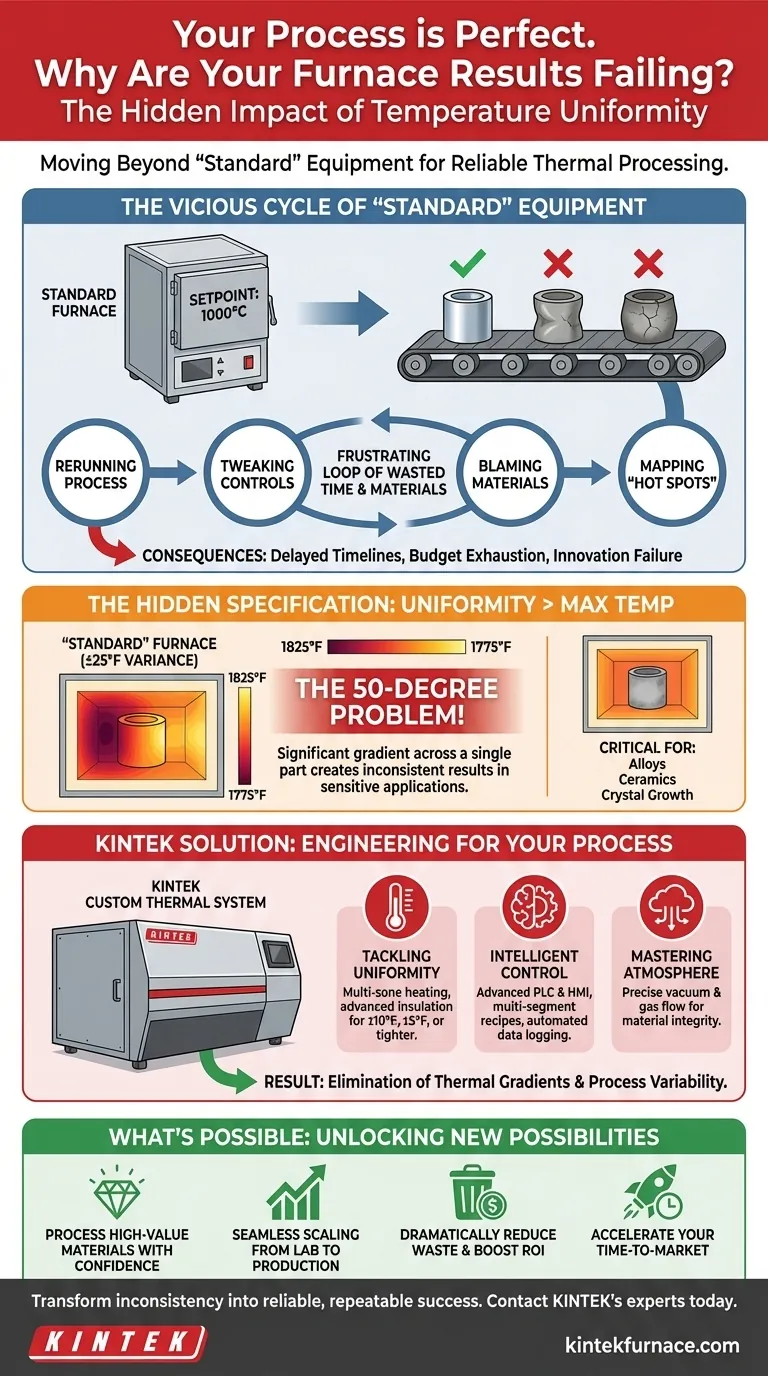

The Vicious Cycle of "Standard" Equipment

If this scenario feels familiar, you are not alone. Many laboratories and manufacturing facilities invest in a "standard" box or tube furnace based on two primary specifications: maximum temperature and chamber size. It seems logical. If you need to process at 1000°C, a furnace rated for 1200°C should be more than capable, right?

This assumption leads to a costly cycle of troubleshooting:

- Rerunning the Process: Hoping that the next batch will magically turn out right.

- Tweaking the Controls: Adjusting ramp rates or soak times on the basic controller, treating the symptom rather than the cause.

- Blaming Materials: Questioning your raw material supply, even when it has passed all incoming inspections.

- Mapping "Hot Spots": You may even notice that samples placed in the center of the furnace behave differently than those near the edges, but you lack the tools to fix it.

The commercial consequences are severe. Project timelines are delayed, R&D budgets are exhausted by material waste, and promising innovations fail to scale because the process isn't repeatable. Confidence in your own data begins to erode. The furnace, intended to be a reliable workhorse, becomes the biggest variable in your entire operation.

The Hidden Specification: Why Uniformity Matters More Than Max Temp

Here is the turning point: The problem isn’t your process. It’s that you're using a generalist tool for a specialist's job. The most critical performance metric of a furnace is often buried in the fine print of a spec sheet: temperature uniformity.

A standard furnace might be rated for ±25°F (or ~±15°C). This is perfectly acceptable for bulk, non-critical processes like general annealing. But what does it mean for your advanced application?

The 50-Degree Problem in a "Standard" Furnace

Imagine your process requires a critical soak at 1800°F. With a uniformity of ±25°F, one part of your component could be experiencing 1775°F while another part is simultaneously at 1825°F. That’s a 50-degree temperature gradient across a single part.

For sensitive metal alloys, advanced ceramics, or crystal growth, this 50-degree variance is the difference between success and catastrophic failure. It’s why one side of a part is perfectly sintered while the other is under-processed. This is the fundamental, physics-based reason why your results are inconsistent. The "common solutions" fail because they can't change the thermal dynamics of the furnace chamber. Tweaking a simple controller cannot correct a 50-degree temperature gradient engineered into the very design of the furnace.

Moving Beyond "Standard": Engineering a Furnace for Your Process

To achieve true process control, you don't need a slightly better standard furnace. You need a thermal system engineered specifically for your desired outcome. This requires a tool designed from the ground up to deliver what actually matters: exceptional temperature uniformity, precise atmospheric control, and intelligent automation.

This is the core principle behind KINTEK’s solutions. We don’t just sell furnaces; we engineer customized thermal processing systems based on a deep understanding of our clients' challenges.

From General-Purpose Box to Precision Instrument

Instead of being limited by off-the-shelf specifications, our approach targets and solves the root cause of process variability:

- Tackling Uniformity Head-On: Where a standard furnace offers ±25°F, we can design multi-zone heating systems with advanced insulation packages to deliver uniformity of ±10°F, ±5°F, or even tighter. This eliminates the thermal gradients that cause inconsistent results.

- Providing Intelligent Control: Instead of basic controllers, we integrate advanced PLC and HMI systems. This allows for complex, multi-segment recipes, automated data logging for process validation, and seamless integration with your workflow.

- Mastering the Atmosphere: For materials sensitive to oxidation, our vacuum and atmosphere furnace systems are designed to provide the exact environment your process demands, ensuring the chemical and physical integrity of your materials.

Our process starts not with a catalog, but with your requirements. By leveraging our R&D expertise and in-house manufacturing, we build the precise tool you need to get the job done right, every time.

What's Possible When Your Furnace Is No Longer the Variable?

When your furnace transforms from a source of uncertainty into a reliable, precision instrument, it unlocks entirely new possibilities. The energy your team once spent on troubleshooting can now be focused on innovation.

With a KINTEK custom-engineered furnace, you can:

- Process High-Value Materials with Confidence: Work with sensitive, next-generation materials that were previously too risky or difficult to process repeatably.

- Seamlessly Scale from Lab to Production: Develop a process in R&D knowing it can be scaled up with predictable, consistent results.

- Dramatically Reduce Waste: Eliminate failed batches and wasted material, delivering a direct and significant return on your investment.

- Accelerate Your Time-to-Market: By removing a major source of process variability, you can get new products and innovations to market faster than your competition.

Your furnace should be a competitive advantage, not a bottleneck. Stop battling a general-purpose tool and let us build the specific solution your work deserves.

Solving process variability is about more than just better hardware; it's about having an expert partner who understands the deep connection between thermal dynamics and material science. Our team is ready to discuss the unique challenges of your project and design a thermal system that transforms inconsistency into reliable, repeatable success. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

- Beyond the Checklist: Why Your High-Temperature Furnace Fails (And How to Ensure It Won't)

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- The Invisible Saboteur: Why Your High-Temp Furnace Fails (And How to Stop It)