You’ve done everything right. The material synthesis was flawless, the sample preparation meticulous, and the furnace cycle programmed exactly to protocol. You wait hours, anticipating a successful result. Yet, when you open the chamber, the sample is cracked, warped, or exhibits properties that are wildly inconsistent with the last batch. The entire run is a write-off.

It’s a deeply frustrating scenario, one that plays out in R&D labs and production facilities far too often.

Chasing Ghosts: Why Your Troubleshooting Hits a Dead End

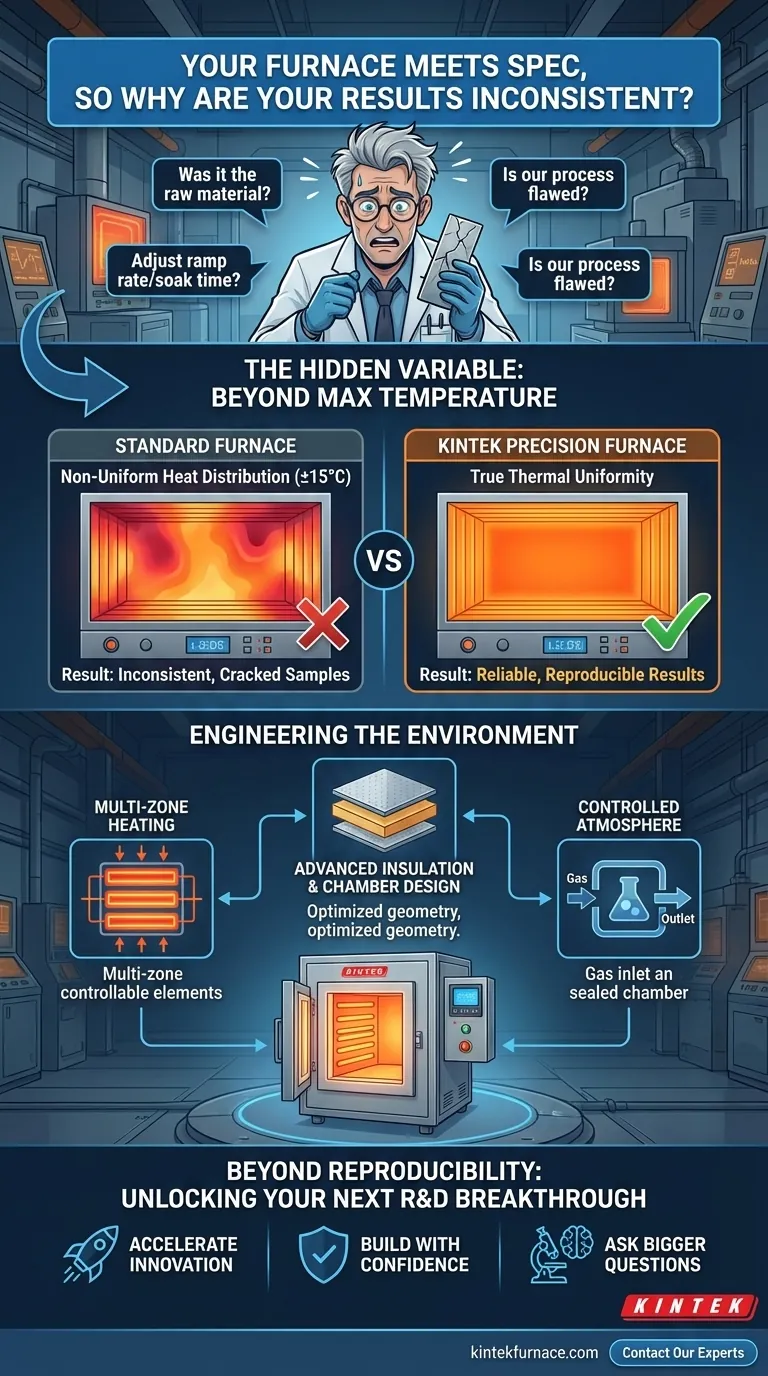

When faced with inconsistent thermal processing results, the troubleshooting cycle begins. You start to question everything:

- "Was there an issue with the raw material?" You spend time and money analyzing a new batch, only to get the same unpredictable outcome.

- "Should I adjust the ramp rate or soak time?" You run dozens of iterative tests, burning through valuable time and expensive materials, yet the results remain stubbornly unreliable.

- "Is our process fundamentally flawed?" Doubt creeps in, threatening the timeline of a critical project.

This cycle of trial and error is more than just frustrating; it has severe business consequences. Each failed batch represents wasted materials, lost man-hours, and delayed project milestones. For a company trying to innovate, this uncertainty is a direct barrier to developing new materials, improving product quality, and getting to market faster.

You check the furnace’s spec sheet again. It's rated for the correct maximum temperature, so the equipment should be working. The problem, however, is rarely the furnace's ability to get hot. The problem is a hidden variable that most standard spec sheets don't adequately address.

The Hidden Variable: Beyond Max Temperature to True Thermal Uniformity

The fundamental misunderstanding that leads to this struggle is the difference between a furnace's maximum temperature and its temperature uniformity.

Think of a home oven. You know there are hot spots where cookies on the edge of the tray burn, and cooler spots where the ones in the middle are undercooked. A standard industrial or lab furnace, despite being far more advanced, operates on a similar principle. While the controller’s sensor might read a stable 1000°C, one corner of the chamber could be 985°C while another is 1015°C.

For many basic applications, this standard uniformity of ±15°C (or ±25°F) is acceptable. But for advanced materials science, semiconductor research, or aerospace components, that temperature gradient is a disaster. It means one part of your sample is undergoing a different thermal process than another, leading to internal stresses, incomplete phase transitions, and inconsistent grain structures—the very root of the failures you're experiencing.

This is why your previous troubleshooting failed. Adjusting ramp rates or blaming raw materials is like trying to fix a crooked picture by repainting the wall. You are addressing symptoms, not the root cause: the thermal environment itself is not uniform enough for your specific application.

Engineering the Environment: From a Standard Box to a Precision Tool

To solve this problem permanently, you don’t just need a box that gets hot. You need a precisely controlled thermal environment engineered for your exact process. The solution lies in specifying a furnace where temperature uniformity is a primary design criterion, not an afterthought.

This is where KINTEK's deep customization capability becomes critical. A truly precise furnace is a system designed from the ground up to eliminate thermal variance. This is achieved by engineering key components to work in harmony:

- Multi-Zone Heating: Instead of one massive heat source, multiple, independently controlled heating zones are used. Smart controllers actively adjust power to each zone, neutralizing hot and cold spots to maintain a uniform temperature field across the entire workload.

- Advanced Insulation and Chamber Design: High-efficiency ceramic fiber insulation isn't just for saving energy; it's about preventing heat loss in specific areas, which is a major cause of temperature gradients. The chamber geometry itself is optimized to promote even heat distribution.

- Controlled Atmosphere: Introducing an inert gas like argon or nitrogen can improve heat transfer and prevent unwanted chemical reactions, but only if the chamber is properly sealed and gas flow is managed. Our atmosphere furnaces are designed to ensure the gas provides a consistent, stable environment.

A KINTEK furnace isn't an off-the-shelf product; it's the physical embodiment of a solution. It is designed based on a deep understanding of the thermal physics that dictates experimental success. We build the tool that delivers the precise, uniform environment your work demands.

Beyond Reproducibility: Unlocking Your Next R&D Breakthrough

When your furnace delivers a truly uniform thermal environment, everything changes. The "ghost" variables disappear, and your results become reliably reproducible. But the benefits go far beyond simply fixing a nagging problem.

- Accelerate Innovation: You can stop wasting weeks troubleshooting and start focusing on genuine R&D. You can confidently test more sensitive, next-generation materials that were previously impossible to process reliably.

- Build with Confidence: You can trust that the material properties you characterize in the lab can be consistently reproduced, enabling a smoother transition from research to pilot production.

- Ask Bigger Questions: With a stable and predictable processing environment, you can begin to explore the finer nuances of your materials, pushing the boundaries of what's possible and securing a competitive edge.

Your material, your process, and your research goals are unique. A one-size-fits-all furnace will always be a source of compromise and uncertainty. To move forward, you need a partner who understands the physics behind your challenges and can engineer the precise solution you require.

Let's discuss the specific thermal challenges you're facing in your projects. Our team is ready to help you configure a furnace that eliminates inconsistency and empowers your next breakthrough. Contact Our Experts.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Why Your Crystal Growth Experiments Are Failing: The Hidden Culprit in Your Tube Furnace

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good

- Why Your High-Temperature Furnace Delivers Inconsistent Results—And How Geometry Is the Key to Fixing It