You know the feeling. Weeks of preparation, a valuable and carefully prepared sample loaded, and a critical high-temperature process running in your vacuum furnace. You wait, hopeful. But when you inspect the results, it’s a disaster. One part of the sample is perfectly treated, while another is under-processed or, worse, damaged by a hot spot. The data is unusable. The batch is ruined. The clock has to be reset.

If this scenario sounds painfully familiar, you're not alone.

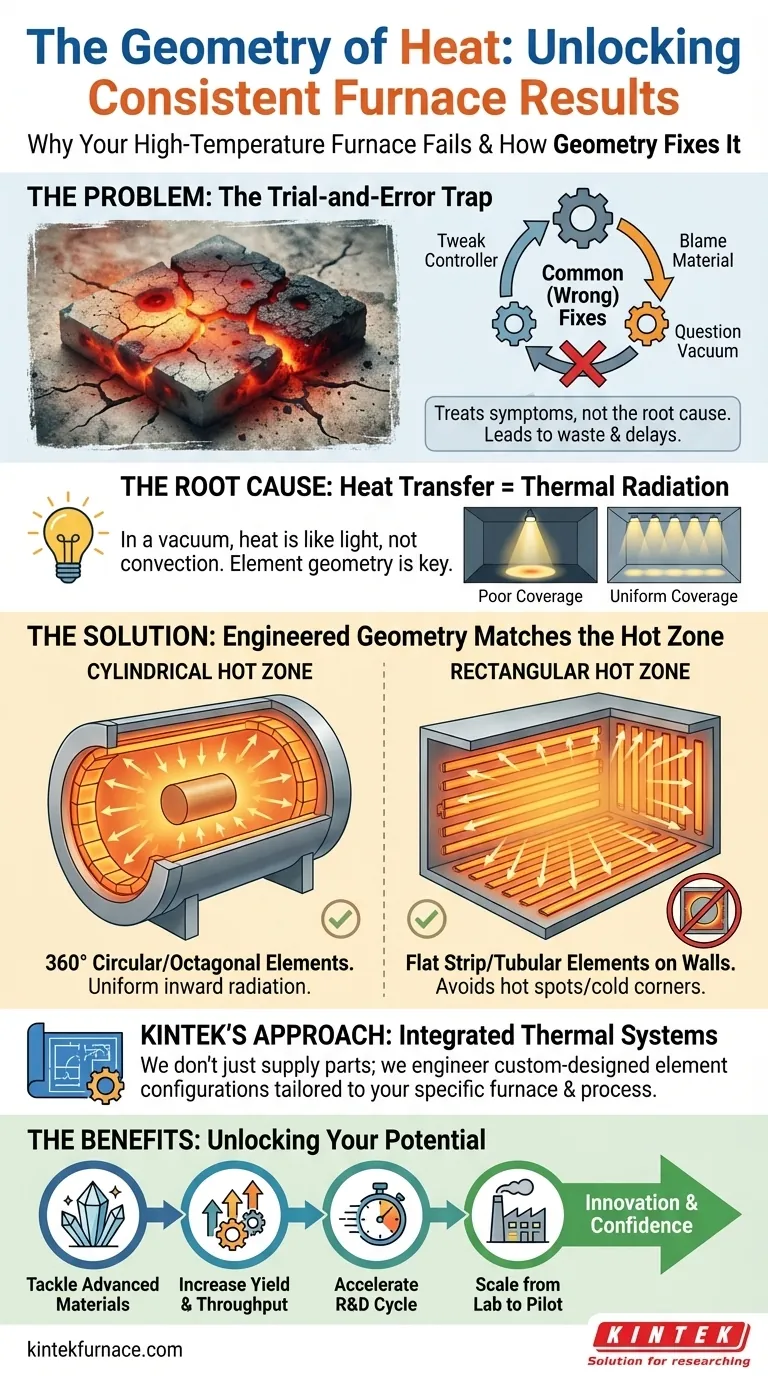

The Trial-and-Error Trap: Why Common Fixes Don't Work

Across countless advanced material labs and production facilities, this struggle with inconsistent thermal processing is a constant source of frustration. In response, teams often fall into a predictable and costly cycle of troubleshooting:

- Tweak the controller: "Maybe if we just increase the setpoint by a few degrees or extend the soak time?"

- Blame the material: "Perhaps this graphite element is just old. Let's order a standard replacement."

- Question the vacuum: "Is the pump pulling a deep enough vacuum? Let's spend a day checking for leaks."

While these factors can play a role, they are rarely the true culprit. These efforts are often shots in the dark, treating symptoms instead of the underlying disease.

This isn't just an academic problem; it has severe business consequences. Each failed run translates directly into wasted high-value materials, critical project delays that push back product launches, and a growing uncertainty that erodes confidence in your lab's capabilities.

The Root Cause Hiding in Plain Sight: It’s Not the Heat, It’s the Shape

The reason so many attempts at a fix fail is that they overlook a fundamental principle of physics. In the vacuum of a furnace, heat transfer happens almost exclusively through thermal radiation.

Think of your heating element not as a conventional heater, but as a set of powerful light bulbs. To illuminate a room evenly, you wouldn’t use a single, intense spotlight in one corner. You would arrange multiple lights to ensure every part of the room receives uniform coverage.

It's precisely the same with heat in your furnace. The physical geometry of the heating element is a deliberate engineering choice designed to "illuminate" your sample with uniform thermal energy.

- For a cylindrical furnace chamber (hot zone), the ideal solution is a 360° circular or octagonal heating element arrangement. This design surrounds the workload, radiating heat inward evenly from all directions, ensuring exceptional temperature uniformity.

- For a rectangular hot zone, a circular element would be a disaster, creating intense hot spots and cold corners. Here, flat strip or tubular elements must be carefully arranged along the walls to create a uniform field of radiant heat.

This is why simply replacing an aging element with another of the same type, if it was incorrectly specified to begin with, will only perpetuate the cycle of failure. You're just putting a new bulb into the same poorly placed lamp.

From Off-the-Shelf Parts to Engineered Systems: The Right Tool for the Job

To solve the problem of thermal non-uniformity permanently, you need to stop thinking about heating elements as interchangeable parts and start thinking about the furnace as an integrated thermal system. The solution requires a tool where the heating element's geometry is perfectly engineered to match the furnace's hot zone and your specific application.

This is the core of KINTEK's design philosophy. We don't build furnaces from a catalog of standard components; we engineer complete, customized solutions based on a deep understanding of thermal dynamics.

Our exceptional R&D and in-house manufacturing capabilities allow us to design and build the exact heating element configuration your process demands.

- For standard applications: We perfect the 360° graphite heating systems in our cylindrical furnaces to deliver best-in-class uniformity.

- For unique requirements: Our deep customization expertise shines. Whether you need a large rectangular chamber for batch processing or a complex geometry for a CVD system, we design the flat strip or tubular element array that guarantees uniform heat, every time.

Our products are the embodiment of this principle: they are designed from the ground up to solve the fundamental problem of heat distribution, not just to contain a heat source.

Beyond Consistency: Unlocking the Full Potential of Your Research

When you eliminate temperature inconsistency as a variable, you're not just fixing a persistent problem—you are unlocking a new level of potential for your work.

Suddenly, you can:

- Tackle more advanced materials that have a very narrow processing window and are intolerant to temperature variations.

- Increase throughput and yield by eliminating batch failures and the need for costly rework.

- Accelerate your R&D cycle because you can trust your results, allowing you to move from one successful experiment to the next with confidence.

- Scale your process from the lab to pilot production, knowing that the thermal principles that worked for a small sample will hold true for a larger one.

You move from a defensive position of constant firefighting to an offensive one of innovation, pushing the boundaries of what's possible.

Solving the puzzle of thermal uniformity is about more than just a single component; it’s about designing an integrated system tailored to your specific goals. If you're tired of battling inconsistent results and want to ensure your thermal processes are reliable, repeatable, and robust, our team is ready to help. We specialize in moving beyond one-size-fits-all solutions to engineer custom furnaces that empower your most ambitious projects. Let's discuss the unique challenges you're facing. Contact Our Experts.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- Why Your Crystal Growth Experiments Are Failing: The Hidden Culprit in Your Tube Furnace

- Why Your High-Temperature Experiments Fail—And How to Fix Them for Good

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace