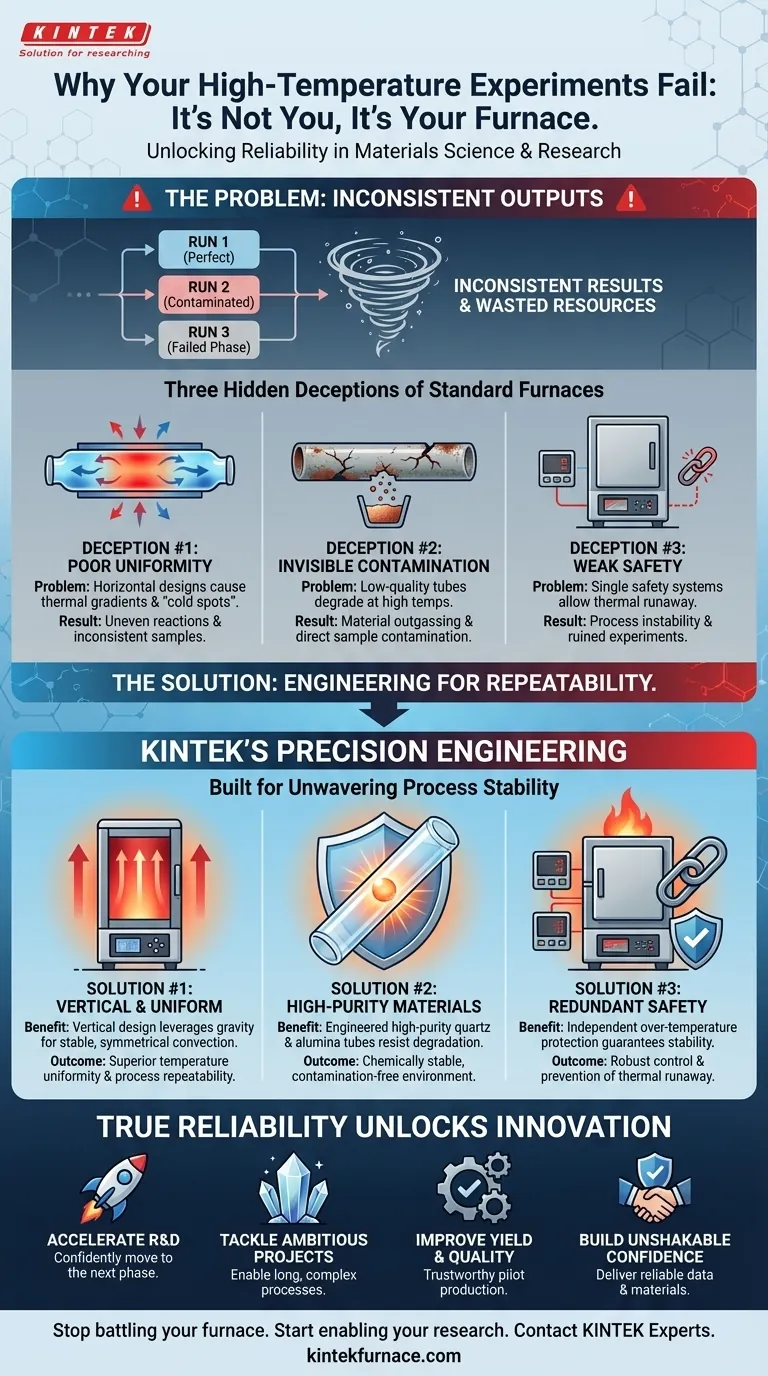

You’ve run the same high-temperature process three times this week. The first run was perfect. The second produced a contaminated sample. The third failed to achieve the desired material phase. The parameters were identical, yet the results are scattered across the board. You're left questioning your materials, your methodology, and maybe even your sanity. This isn't just a minor inconvenience; it's a barrier to progress.

The Frustration of Identical Inputs, Inconsistent Outputs

This scenario is frustratingly common in materials science, chemistry, and semiconductor research. A furnace is expected to be a reliable workhorse—a stable environment where controlled reactions can happen. Yet, for many labs, it becomes a source of unpredictable variables that are maddeningly difficult to pin down.

When an experiment yields inconsistent results, the troubleshooting checklist is predictable:

- "Let's re-verify the precursor materials."

- "Maybe we should clean the chamber again."

- "Let’s recalibrate the temperature controller and run it one more time."

Each of these steps consumes valuable time and expensive, high-purity materials. The business consequences are severe. Project timelines stretch from weeks into months. R&D budgets are drained by repetitive, non-productive runs. Most importantly, confidence in your lab's ability to produce reliable, scalable results begins to erode. You're stuck chasing ghosts in the system instead of innovating.

The Real Culprit: When Your Furnace Becomes the Uncontrolled Variable

The problem is that we often treat the furnace as a simple "hot box." We assume that if the display reads 1000°C, the entire process environment is a stable, pure, and uniform 1000°C. But the reality is far more complex. The root cause of your inconsistency is often not your process, but the furnace’s fundamental design philosophy.

Common "solutions" fail because they only address the symptoms. The real problem lies in three hidden deceptions baked into many standard furnace designs.

Deception #1: The Myth of "Good Enough" Temperature Uniformity

A single temperature reading at the center of a furnace tube can be misleading. In reality, significant temperature gradients can exist along the length of the sample. These "cold spots" can cause uneven reactions, incomplete crystallization, or inconsistent film deposition. In a horizontal tube furnace, natural convection can be asymmetrical and turbulent. However, a vertical furnace orientation uses gravity to its advantage, creating a more stable, symmetrical convection column. This inherently leads to superior temperature uniformity—a critical but often overlooked factor for process repeatability.

Deception #2: The Invisible Contamination from Within

When a sample is contaminated, we tend to look for external sources. But what if the contaminant is coming from the furnace itself? At extreme temperatures, the furnace tube material is under immense stress. A low-quality tube can degrade, outgas, or shed microscopic particles that directly contaminate your sample. This is why the choice of tube material is not a minor detail; it's the foundation of process integrity. Using high-purity quartz or alumina ceramic tubes that are engineered to resist thermal shock and chemical corrosion is the only way to ensure your processing environment remains pristine run after run.

Deception #3: Viewing Safety as a Checkbox, Not a Performance Feature

Safety features like over-temperature protection are often seen merely as a way to prevent catastrophic failure. But they are much more than that. A system with a secondary, independent over-temperature controller isn't just safer; it's a sign of a more robust and stable control philosophy. This same precision prevents subtle thermal runaway events that can ruin an experiment long before they trigger an alarm. Redundant safety systems are a direct indicator of a furnace built for unwavering process stability, ensuring the temperature you set is the temperature you consistently get.

From Unstable Box to Precision Instrument: Engineering for Repeatability

To achieve true consistency, you don't need to work harder at troubleshooting. You need a better tool—one that is engineered from the ground up to eliminate these hidden variables. A truly reliable furnace is not just an assembly of heating elements and controllers; it's an integrated system designed to create a perfectly stable and pure processing environment.

This is the design philosophy behind KINTEK’s advanced furnace solutions. We recognize that true reliability is the outcome of intentional engineering choices:

- Solving Uniformity at the Source: Our vertical tube furnaces are designed to leverage natural physics for superior temperature uniformity, ensuring your entire sample experiences the exact same thermal conditions.

- Guaranteeing Process Purity: We utilize only high-purity furnace tube materials, building a foundation of chemical and thermal stability that prevents the furnace itself from becoming a source of contamination.

- Embedding Stability in Safety: Our furnaces incorporate robust, automated protection systems. These features provide more than just safety; they deliver the rock-solid thermal control necessary for the most sensitive and repeatable processes.

Beyond Troubleshooting: What Will You Achieve with True Reliability?

When your furnace transforms from an unpredictable variable into a dependable constant, it unlocks entirely new possibilities. The time and resources once spent on re-running failed experiments can be reinvested into genuine innovation.

With a truly reliable furnace, you can:

- Accelerate Your R&D Cycle: Confidently move on to the next phase of your research instead of repeating the last one.

- Tackle More Ambitious Projects: Undertake longer, more complex processes like large-format crystal growth or multi-day annealing, knowing the environment will remain stable.

- Improve Process Yield and Quality: Transition from research to pilot production with a process you can trust to deliver consistent, high-quality results.

- Build Unshakable Confidence: Deliver data and materials that are reliable, repeatable, and ready for the next stage of development or commercialization.

Your work is too important to be derailed by unreliable equipment. Stop battling your furnace and start enabling your research. If you're ready to move past the cycle of inconsistent results and unlock the full potential of your lab, our team of experts is here to help you configure a furnace solution built for the precision and reliability your work demands. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- Why Your High-Temperature Furnace Fails: It’s Not the Heating Element, It’s the Physics

- Why Your Thermal Processing Fails: The Hidden Mismatch in Your Furnace

- Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing