You’ve done everything right. The design is flawless, the machining is to the micron, and the assembly is meticulously prepared. You complete the joining process, and then comes the moment of truth: you place the part on the inspection table, only to find it’s twisted, bent, or warped. A high-value, complex component is now scrap. Hours of skilled labor and expensive materials are wasted, and the project timeline has taken a serious hit.

This frustrating scenario is a familiar story in advanced manufacturing, especially when dealing with complex geometries or tight tolerances. It's a problem that sends engineers and technicians on a frustrating and often fruitless quest for a solution.

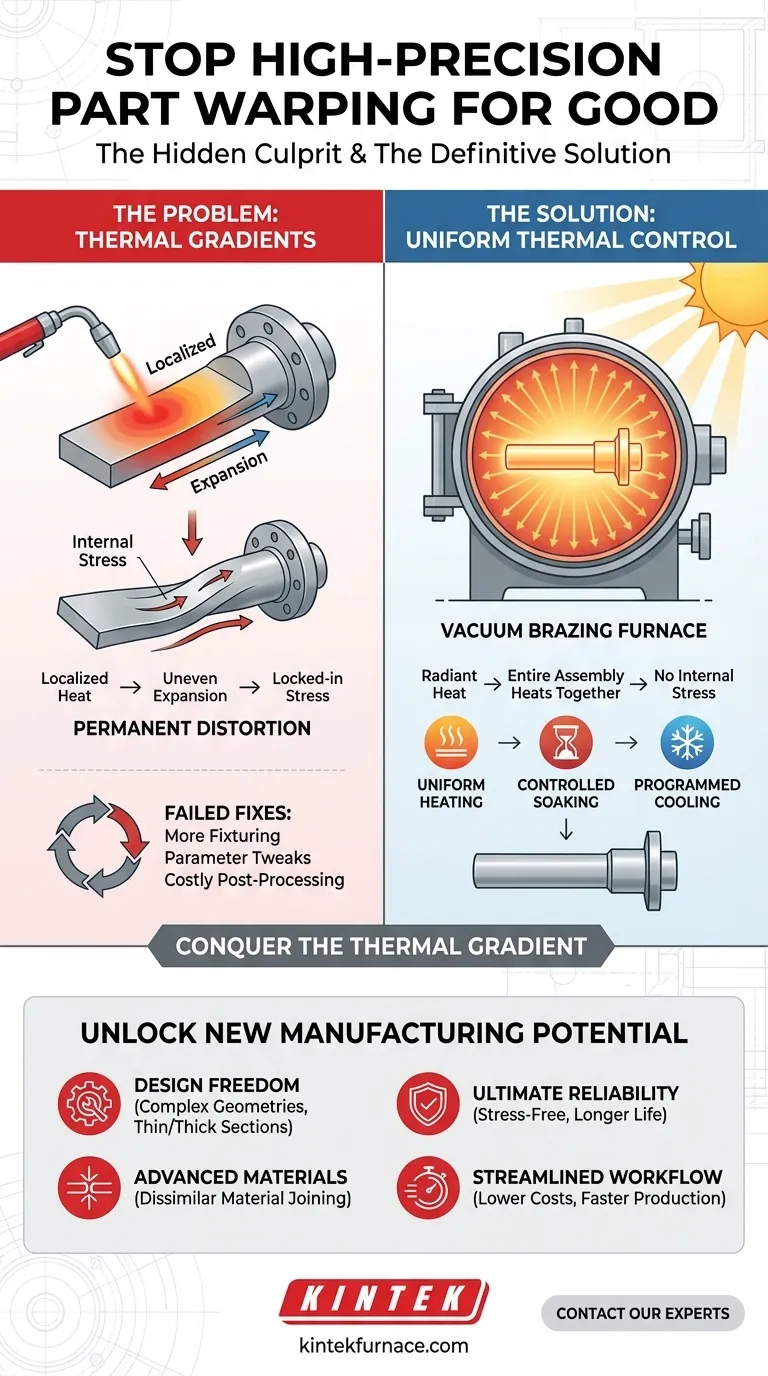

Wrestling with Symptoms: The Cycle of Failed Fixes

When distortion occurs, the immediate reaction is often to treat the symptoms. Teams might try:

- More complex and rigid fixturing: Attempting to physically force the part to hold its shape.

- Altering welding or torch parameters: Tweaking the technique in hopes of finding a magic combination.

- Implementing costly post-processing steps: Adding straightening, machining, or stress-relieving operations that introduce their own costs, delays, and potential for error.

These efforts may yield marginal improvements, but they rarely solve the problem at its core. That’s because they fail to address the fundamental physics at play.

The business consequences of this ongoing struggle are significant. It leads to unpredictable production schedules, inflated manufacturing costs due to high scrap rates, and—most critically—a compromised final product. A part that has been "corrected" after warping can still harbor hidden internal stresses, making it a candidate for premature failure in the field.

The Hidden Culprit: It's Not Just the Heat, It's the Difference in Heat

The root cause of distortion is not simply the application of heat. It is a thermal gradient—a significant difference in temperature across different areas of the same component at the same time.

Here’s the simple physics:

- Metal Expands When Heated: When you apply a concentrated heat source like a welding arc or a torch flame to a joint, that small area gets extremely hot, very quickly. It tries to expand.

- Internal Stresses Form: The surrounding cool metal resists this expansion, creating immense internal stress. This is like trying to force a puzzle piece into a space that's too small.

- Distortion Becomes Permanent: As the part cools unevenly, these stresses become "locked in," pulling and twisting the material out of its intended shape.

The common fixes fail because they are fighting a battle against physics. No amount of clamping can completely overcome the powerful forces of thermal expansion and contraction. You are merely wrestling with the symptom, not curing the disease.

The Solution Embodied: Conquering the Thermal Gradient

To truly eliminate distortion, you must stop creating severe thermal gradients in the first place. This requires a fundamental shift in approach: instead of heating a small part of the assembly, you must heat the entire assembly as a single, unified system.

This is the core principle behind a vacuum brazing furnace.

It is a tool designed from the ground up to achieve ultimate thermal control. By removing the atmosphere inside the chamber, the furnace changes the way heat is transferred. Instead of the chaotic, localized heat of a flame (convection), it uses radiant heat.

Think of it like the difference between standing in front of a powerful space heater and standing in the gentle, all-encompassing warmth of the sun. Radiant heat warms all surfaces of your component—top, bottom, and deep inside complex channels—simultaneously and gently.

The process ensures:

- Uniform Heating: The entire assembly is slowly brought up to brazing temperature together. No single area gets hotter faster than another, preventing the formation of internal stress.

- Controlled Soaking: The component is held at a stable, uniform temperature, allowing the brazing alloy to flow into the joints cleanly.

- Programmed Cooling: Just as critically, the entire assembly is cooled at a slow, controlled rate. This allows the whole part to contract together, preventing new stresses from forming and locking in perfect dimensional accuracy.

At KINTEK, we don't just build furnaces; we engineer complete thermal management solutions. Our deep customization capabilities mean we design vacuum furnace systems—from muffle and tube furnaces to advanced CVD systems—that are precisely tailored to the mass, geometry, and material of your specific components, ensuring that the principle of uniform thermal control is perfectly executed every time.

Beyond the Fix: Unlocking New Manufacturing Potential

When you eliminate distortion at its source, you do more than just solve a nagging production problem. You open the door to new levels of innovation and efficiency.

- Design Freedom: Engineers can create more complex and ambitious designs, joining thin walls to thick sections or creating intricate internal channels without fear of distortion.

- Advanced Materials: You can reliably join dissimilar materials, like ceramic to metal, that would be impossible with conventional methods.

- Ultimate Reliability: Your components are free from residual stress, leading to superior performance and a longer operational life, which is non-negotiable in aerospace, medical, and other critical industries.

- Streamlined Workflow: By eliminating the need for post-process straightening or stress-relieving, you shorten your overall production time, lower costs, and create a more predictable manufacturing process.

Solving distortion isn't just a technical victory; it's a strategic advantage that allows you to build better products, faster and more reliably than your competition. If you're ready to stop wrestling with the symptoms of thermal distortion and start addressing the root cause, our team is here to help you design the perfect thermal process for your most critical components. Contact Our Experts to discuss your unique application.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- Your Vacuum Furnace Is a System, Not a Component—Here’s Why That Changes Everything

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- Engineering for Zero Failure: The Indispensable Role of Vacuum Furnaces in Aerospace

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace