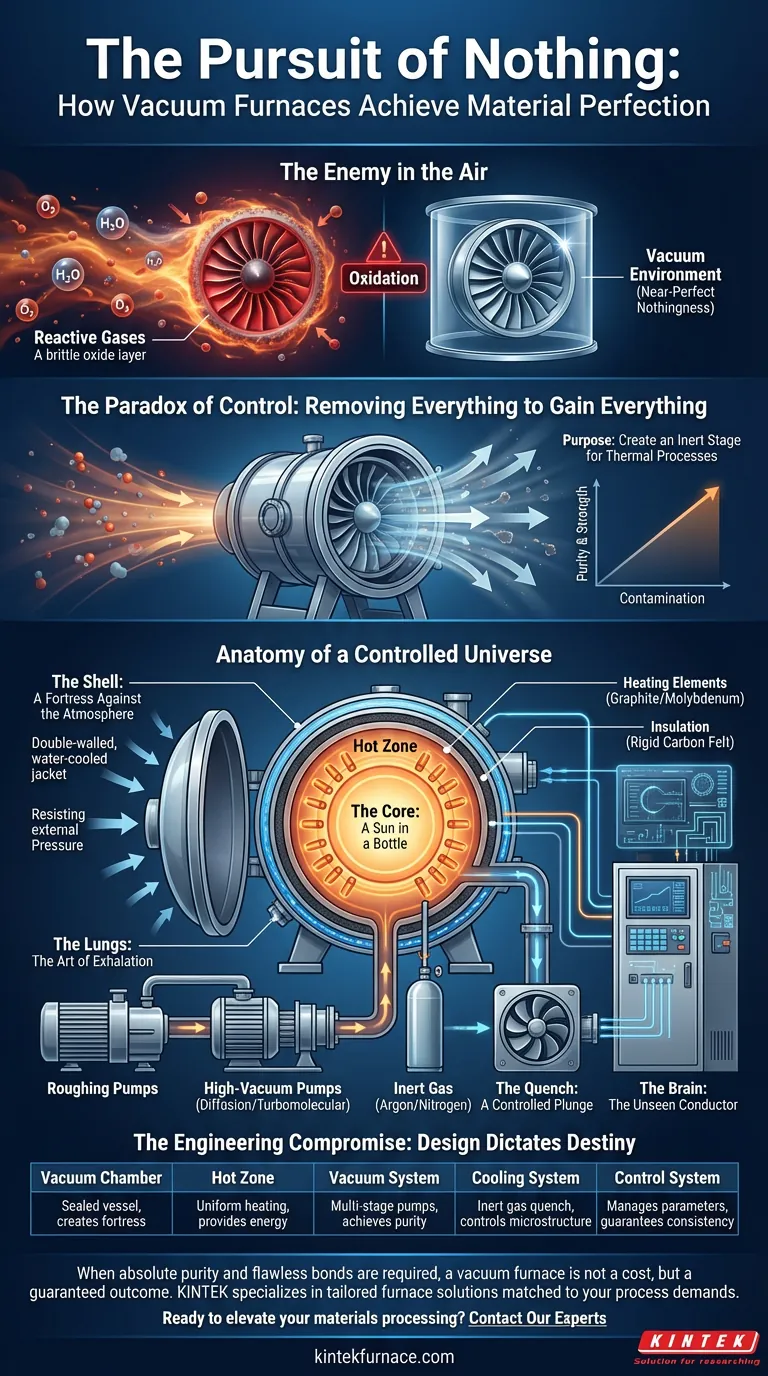

The Enemy in the Air

Imagine a jet engine turbine blade, spinning at 10,000 RPM while glowing cherry-red. It’s forged from a superalloy, a material pushed to the absolute limits of physics. Its survival depends on flawless internal structure and a perfectly clean surface.

The greatest threat to this perfection isn't just the extreme heat of its operating environment, but the very air we breathe. At high temperatures, the oxygen in the atmosphere becomes a highly reactive agent, aggressively attacking the metal's surface. This is oxidation.

This reaction doesn't just cause discoloration. It creates a brittle, microscopic layer of contamination—a seed of potential failure. For critical components in aerospace, medical implants, or advanced electronics, such a flaw is unacceptable.

The solution is not to fight the air, but to remove it entirely.

The Paradox of Control: Removing Everything to Gain Everything

A vacuum furnace is fundamentally an instrument of control. Its purpose is to create an environment of near-perfect nothingness.

By evacuating the chamber, we remove the reactive gases—oxygen, water vapor, and others. This isn't a passive act; it's the active creation of an inert stage where thermal processes can occur without unwanted chemical side effects.

The psychological drive behind this is the pursuit of certainty. In the controlled void of a vacuum, you eliminate the variable of atmospheric contamination. This ensures that the material you put in is the material you get out, only stronger, purer, and metallurgically cleaner.

This purity allows for processes that are impossible in open air, like high-temperature brazing, where perfectly clean surfaces must meet to form a seamless metallurgical bond.

Anatomy of a Controlled Universe

A vacuum furnace is a complex system where each part serves one master: maintaining the integrity of the void.

The Shell: A Fortress Against the Atmosphere

The vacuum chamber is the first line of defense. Built from high-strength steel, it must withstand over 14 pounds per square inch of external atmospheric pressure trying to crush it. Most high-performance designs, like those from KINTEK, feature a double-walled, water-cooled jacket. This keeps the exterior cool and safe, even when the interior rages at thousands of degrees.

The Core: A Sun in a Bottle

Inside the chamber lies the hot zone—the heart of the furnace. It consists of two key elements:

- Heating Elements: Made from materials like graphite or molybdenum that thrive in a vacuum, these elements are arranged to provide uniform, 360-degree heat.

- Insulation: Layers of rigid carbon felt or graphite paper line the hot zone, trapping thermal energy with incredible efficiency. This allows for rapid heating, precise temperature control, and fast cooling cycles.

The Lungs: The Art of Exhalation

Creating the vacuum requires a multi-stage system of pumps. It’s a process of systematic air removal.

- Roughing Pumps: These mechanical pumps remove the bulk of the air, taking the chamber from atmospheric pressure down to a rough vacuum.

- High-Vacuum Pumps: A diffusion or turbomolecular pump then takes over, capturing the remaining stray molecules to achieve the final, deep vacuum level required for high-purity processing.

The Quench: A Controlled Plunge

After heating, parts often need to be cooled rapidly and uniformly. The furnace achieves this by backfilling the chamber with a high-purity inert gas like argon or nitrogen. A powerful fan circulates this gas, efficiently transferring heat from the parts to the water-cooled chamber walls.

The Brain: The Unseen Conductor

A sophisticated control system is the furnace’s nervous system. It precisely manages the temperature profile and vacuum levels, ensuring every cycle is stable, repeatable, and perfectly aligned with the material's specifications.

The Engineering Compromise: Design Dictates Destiny

Not all vacuum furnaces are created equal. The design is a series of deliberate choices and trade-offs, balancing cost against capability.

The most critical choice is between a "cold wall" and "hot wall" design. Cold wall furnaces, where the heating elements are inside a water-cooled chamber, are the standard for high-performance applications. They enable extremely high temperatures, fast cycles, and superior uniformity.

The primary trade-off is always cost versus certainty. A vacuum furnace is a significant investment because creating and maintaining a perfect void is an engineering challenge. You are paying for the complex pumps, the robust chamber, and the precision controls. What you are buying, however, is not just a machine; it's a guaranteed outcome.

| Component | Primary Function | The "Why" Behind It |

|---|---|---|

| Vacuum Chamber | Sealed vessel to maintain vacuum & withstand pressure | Creates a fortress against atmospheric contamination. |

| Hot Zone | Uniform, high-temperature heating environment | Provides the energy for treatment without hot spots. |

| Vacuum System | Multi-stage pumps to remove air | Achieves the purity needed for advanced processes. |

| Cooling System | Uses inert gas and fans for rapid cooling | Controls the material's final microstructure. |

| Control System | Manages temperature and vacuum for repeatable cycles | Guarantees consistency and quality from batch to batch. |

When your work involves reactive metals like titanium, requires the absolute purity of medical-grade materials, or depends on the flawless bonds of high-strength brazing, the question isn't whether you can afford a vacuum furnace. It's whether you can afford the consequences of not using one.

This is where specialized engineering comes in. At KINTEK, we focus on building Muffle, Tube, and Vacuum Furnace systems that are not just standard products, but tailored solutions. Our deep customization capabilities ensure that your furnace is precisely matched to the demands of your material and your process, giving you absolute control over your results.

Ready to elevate your materials processing with unmatched precision and purity? Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Beyond the Batch: How Continuous Vacuum Furnaces Redefine Industrial Metallurgy