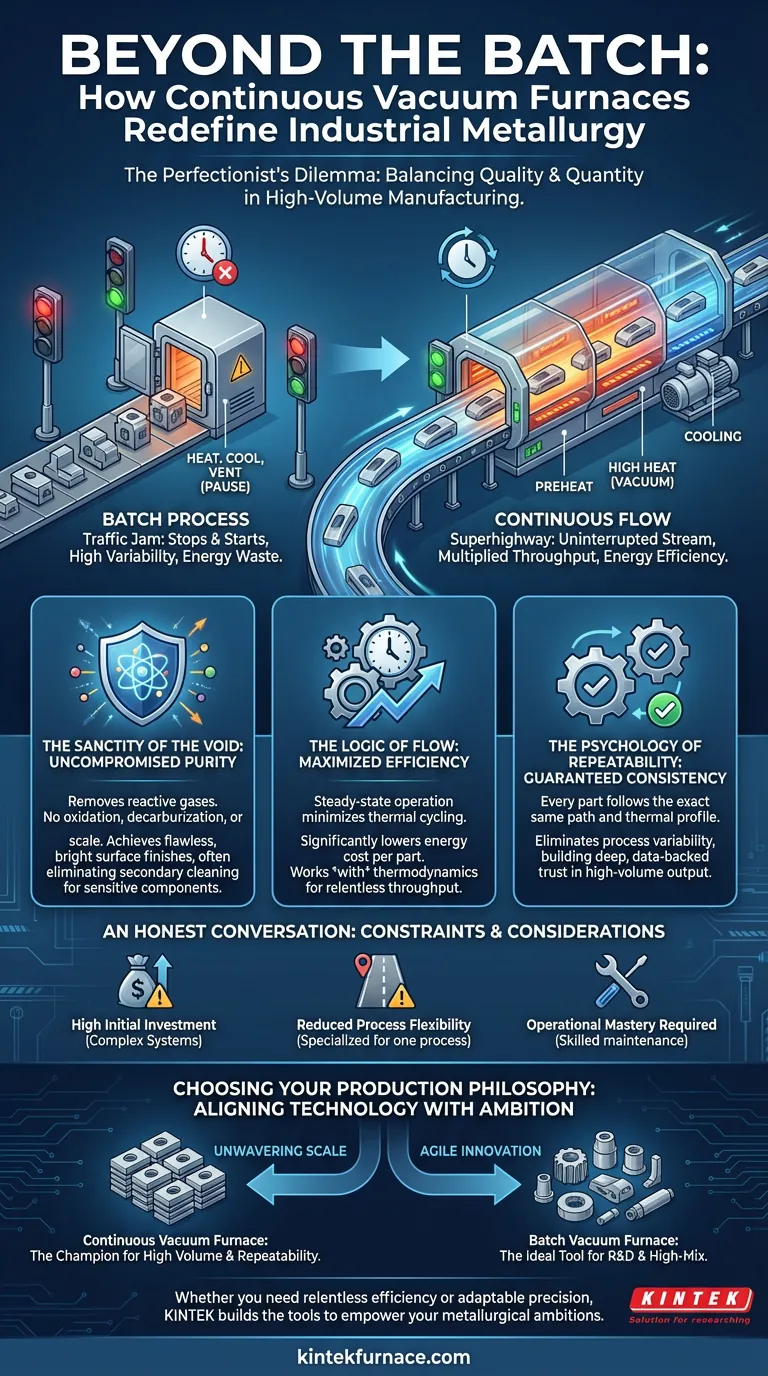

The Perfectionist's Dilemma

In high-volume manufacturing, the goal is not just to make one perfect part. It's to make a million perfect parts, identically. A single component failing due to microscopic material inconsistency can compromise a multi-million dollar aerospace system or a life-saving medical implant.

This creates a fundamental tension: the methods that produce the highest material purity—like vacuum heat treatment—are often slow and deliberate. The methods that deliver speed and scale often introduce variability and compromise.

Engineers face a difficult choice between quality and quantity. The continuous vacuum furnace is the elegant resolution to this paradox. It's where the physics of metallurgical perfection meets the relentless economics of scale.

The Sanctity of the Void

We tend to think of a vacuum as an absence, an emptiness. In metallurgy, it is a precisely controlled presence of nothing. By removing reactive gases like oxygen, we don't just create an empty space; we create an environment where the metal's true potential can be realized without interference.

A Controlled Atmosphere of Purity

At high temperatures, metal is vulnerable. It desperately wants to react with its surroundings. In normal air, this means forming a brittle, flaky layer of oxide (scale) on the surface. It can also lead to decarburization, where carbon leaches from the surface of steel, robbing it of its designed hardness and fatigue life.

A vacuum environment simply removes the threat. It’s a clean room for atoms, ensuring the material that exits the furnace is the same material that was designed on paper, with no unwanted surface chemistry.

The Promise of a Flawless Surface

The result is a workpiece that emerges clean and bright, often with a surface finish that requires no secondary cleaning or machining. For components where every micron matters—like in sensitive electronics or precision gears—this isn't a cosmetic benefit. It's a functional necessity that preserves dimensional accuracy and surface integrity.

The Tyranny of the Clock: The Logic of Continuous Flow

While a vacuum guarantees quality, the continuous process conquers the clock. It fundamentally redesigns the workflow from a series of stops and starts into a smooth, uninterrupted stream.

From Traffic Jam to Superhighway

A traditional "batch" furnace operates like a city street with stoplights. Load, seal, heat, cool, vent, unload. Each step is a pause.

A continuous furnace is a superhighway. Parts move seamlessly through dedicated zones for preheating, heating, and cooling. By eliminating the downtime of cycling the entire furnace for each load, throughput isn't just increased; it's multiplied.

The Physics of Efficiency

This continuous motion is also profoundly more energy-efficient. A batch furnace wastes enormous energy reheating its thermal mass from a low or ambient temperature with every cycle. A continuous furnace holds its distinct zones at a steady operating temperature, minimizing thermal cycling and dramatically lowering the energy cost per part. It works with thermodynamics, not against it.

The Psychology of Repeatability

In a continuous system, every single part follows the exact same path and experiences the exact same thermal profile for the exact same duration. The first part and the ten-thousandth part are treated as identical twins.

This removes process variability and builds a deep, data-backed trust in the output. For industries where quality control is paramount, this level of guaranteed consistency is the ultimate form of operational peace of mind.

An Honest Conversation About Constraints

No single tool is perfect for every job. The power of a continuous vacuum furnace comes with specific trade-offs that demand a clear-eyed assessment.

- High Initial Investment: These are complex, sophisticated systems. Their cost is justified by the return on investment generated through high-volume, continuous production.

- Reduced Process Flexibility: A continuous furnace is a specialist. It is optimized for a specific, repeatable process. It lacks the agility of a batch furnace, which can be easily re-tasked for R&D or high-mix, low-volume production.

- Operational Mastery: The complexity of a multi-zone, automated system requires skilled operation and a robust preventative maintenance schedule to ensure reliability.

Choosing Your Production Philosophy

The right furnace is an extension of your operational strategy. The choice hinges on what you value most.

- For Unwavering Scale: If your mission is to produce a high volume of a single part with maximum efficiency and repeatability, the continuous vacuum furnace is the undisputed champion.

- For Agile Innovation: If you are developing new materials, running varied thermal cycles, or serving a high-mix market, a flexible batch vacuum furnace is your ideal laboratory and production tool.

- When Purity is Paramount: In all cases where material integrity cannot be compromised, a vacuum environment is non-negotiable. Your choice between batch and continuous then becomes a simple question of your required throughput.

Aligning Technology with Ambition

Ultimately, achieving superior material outcomes is about aligning the right furnace technology with your specific metallurgical and business objectives. Whether you require the relentless efficiency of a continuous system or the adaptable precision of a batch furnace, the underlying principles of a controlled thermal process remain the same.

At KINTEK, we build the tools that empower these ambitions. Backed by deep R&D and advanced manufacturing, we provide a comprehensive range of high-temperature solutions, from customizable Vacuum and Tube Furnaces for research to robust systems for industrial production. Our expertise lies in engineering a furnace that doesn't just meet your specifications, but enhances your entire process.

If you are ready to elevate your heat treatment capabilities and achieve new levels of quality and efficiency, we can help build the precise solution for your unique needs. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

Related Articles

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials