The Pursuit of Perfection in an Imperfect World

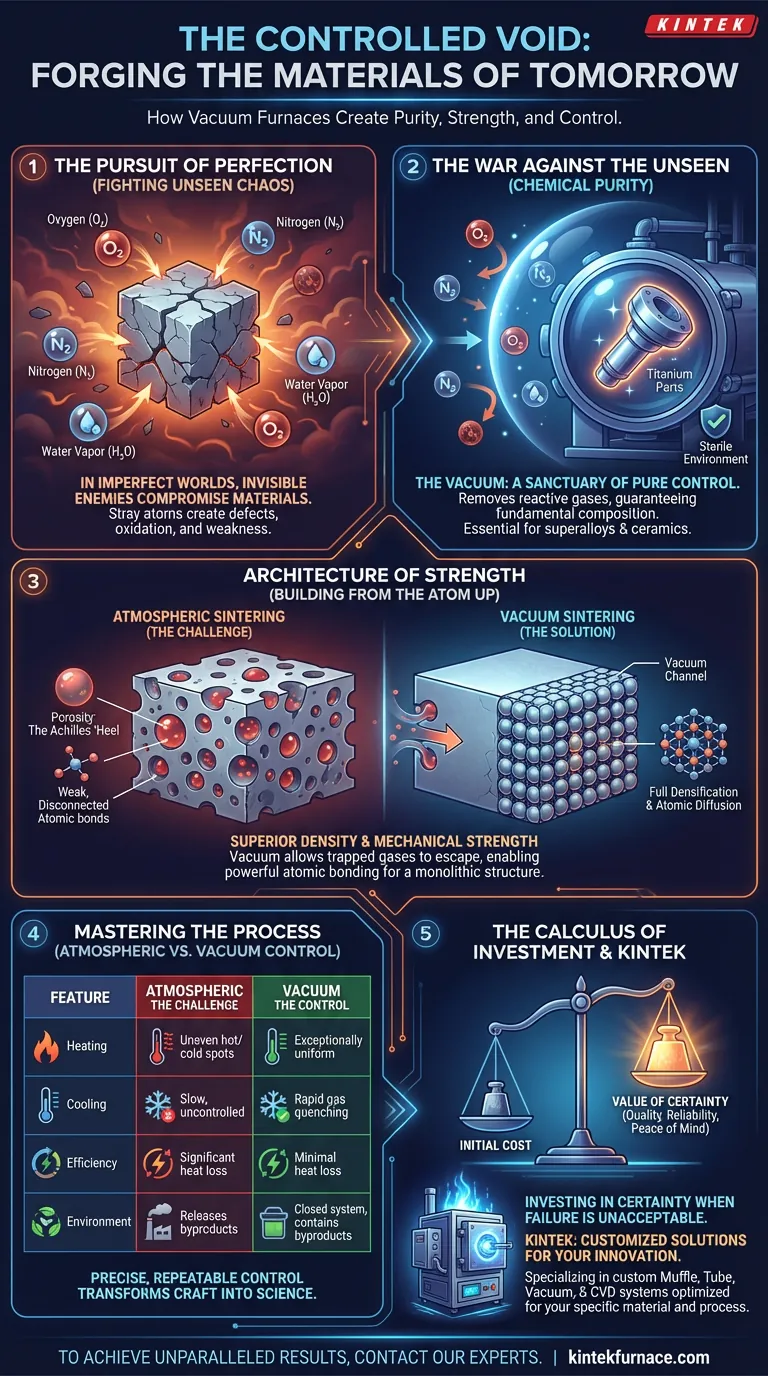

In material science, the greatest enemy is often invisible. It’s the stray oxygen atom that compromises a superalloy's integrity, the trace water vapor that ruins a ceramic's dielectric properties, or the trapped nitrogen that creates a weak point in a sintered part.

Engineers and scientists spend their careers fighting this unseen chaos.

We tend to think of a vacuum as an empty space—a void. But in the context of high-temperature sintering, this is a profound misunderstanding. A vacuum isn't an absence of something; it is the presence of control. It's a purpose-built environment, a sanctuary where materials can become what they were truly designed to be.

The War Against the Unseen: Chemical Purity

The first and most obvious function of a vacuum is to create a chemically pure environment. At high temperatures, materials become highly reactive. An ordinary atmosphere becomes a battlefield of unwanted chemical reactions.

Creating a Sanctuary for Reactive Materials

Imagine forging a part for a satellite from a titanium alloy. In the open air, the high heat would cause oxygen to aggressively bond with the titanium, forming a brittle oxide layer. The material's designed properties would be lost before it was even created.

A vacuum furnace removes the aggressors—oxygen, nitrogen, water vapor—before the battle begins. This is not just about preventing oxidation; it's about guaranteeing the material's fundamental composition remains untarnished. For reactive metals, non-oxide ceramics, and advanced alloys, this sterile environment is non-negotiable.

The Promise of Absolute Purity

This level of purity has tangible consequences. It's the difference between a medical implant that the human body accepts and one it rejects. It's the foundation of a semiconductor that functions flawlessly and one that fails under load.

By eliminating atmospheric contaminants, you aren't just making a cleaner part; you are ensuring its performance, safety, and reliability.

The Architecture of Strength: Building from the Atom Up

Beyond chemical purity, the vacuum directly engineers a material's physical structure, resulting in superior density and mechanical strength.

Escaping the Prison of Pores

During sintering, individual particles of powder are heated until they bond into a solid mass. In a normal atmosphere, gases get trapped in the tiny pores between these particles. These trapped gases act like microscopic pillars, preventing the structure from fully consolidating. The result is porosity—a network of voids that becomes the material's Achilles' heel.

A vacuum acts as an escape route for these trapped gases. As the particles begin to fuse, the vacuum pulls the residual gases out, allowing the structure to collapse into a near-perfectly dense state. This process, called densification, is the key to exceptional strength.

The Freedom to Bond

With atmospheric gases gone, there is nothing to impede the fundamental mechanism of sintering: atomic diffusion. Atoms on the surfaces of adjacent particles are free to move and form powerful, seamless bonds.

The result is a uniform, monolithic structure. You haven't just pressed particles together; you have encouraged them to reform into a single, cohesive whole with a dense and predictable microstructure.

The Conductor's Baton: Mastering the Process

A customized vacuum furnace is a precision instrument. The vacuum itself is a key component that enables a degree of process control that is impossible in other systems.

| Feature | Atmospheric Furnace (The Challenge) | Vacuum Furnace (The Control) |

|---|---|---|

| Heating | Convection currents create uneven hot and cold spots. | Vacuum acts as a perfect insulator, enabling exceptionally uniform heat. |

| Cooling | Slow, uncontrolled cooling can lead to undesirable microstructures. | Allows for rapid gas quenching, precisely locking in desired properties. |

| Efficiency | Significant heat loss to the surrounding atmosphere. | Minimal heat loss, leading to lower energy consumption. |

| Environment | Can release process byproducts into the atmosphere. | A closed system that contains all byproducts, simplifying compliance. |

This control transforms manufacturing from a craft into a science. Every parameter—temperature ramp, vacuum level, cooling rate—can be precisely set and repeated, ensuring that the part you produce today is identical to the one you produce a year from now.

The Calculus of Investment

A vacuum furnace represents a significant investment. The pumps, seals, and control systems add complexity and cost. But the decision is not about initial expense; it's about the cost of failure versus the value of certainty.

When the performance of a single component determines the success of a multi-million dollar aerospace project or a life-saving medical device, the risk of material impurity or structural weakness is unacceptable. The investment in a vacuum furnace is an investment in quality, repeatability, and peace of mind.

This is where customization becomes critical. The required vacuum level for sintering medical-grade titanium is vastly different from that needed for a simple metal tool. A one-size-fits-all solution is either insufficient or excessively expensive.

True process optimization requires a system designed for your specific material, application, and goals. At KINTEK, we specialize in moving beyond standard specifications. Our R&D and manufacturing expertise allows us to engineer custom Muffle, Tube, Vacuum, and CVD furnace systems that provide the exact level of control your process demands. We build the tool that empowers your innovation.

To achieve unparalleled purity, strength, and control in your materials, you need a system as precise as your vision. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- Gravity as an Ally: The Counterintuitive Genius of Vertical Vacuum Furnaces

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Beyond the Batch: How Continuous Vacuum Furnaces Redefine Industrial Metallurgy