A Joint's Silent Story

An aerospace engineer holds a turbine blade assembly. It’s a marvel of metallurgy, but its integrity hinges on a few microscopic joints. A single void, a whisper of oxidation, and the component could fail catastrophically at 30,000 feet.

The strength of that joint wasn't forged by heat alone. It was born in a carefully chosen environment—a vacuum furnace. And the choice of that furnace was not a simple matter of temperature ratings. It was a decision rooted in physics, geometry, and a deep understanding of how materials behave at their limits.

This is the hidden architecture of reliability.

The Sanctity of the Void

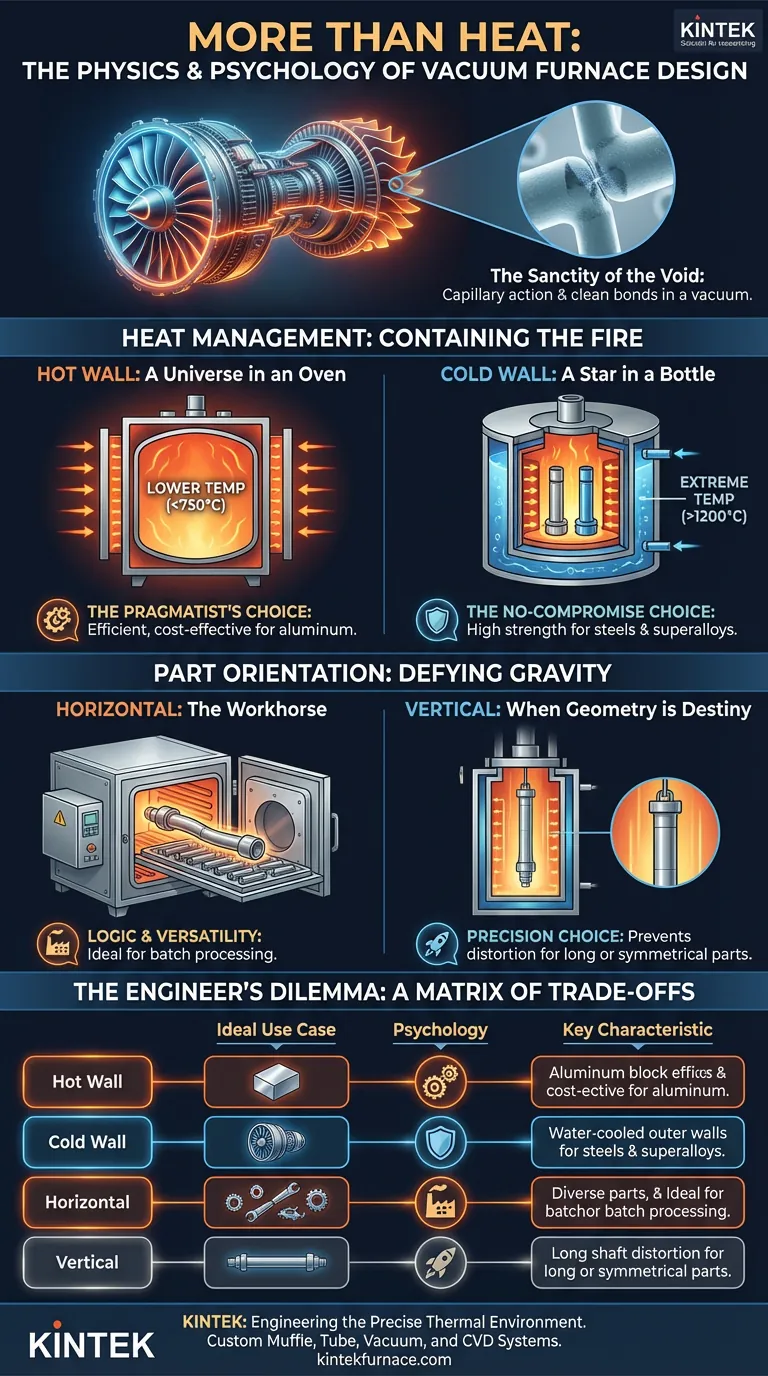

Vacuum brazing is a process of profound elegance. Two components are joined by a filler metal with a lower melting point. In a vacuum, the assembly is heated. The filler melts, flows into the joint via capillary action, and solidifies upon cooling.

The vacuum is the key.

By removing the atmosphere, you remove oxygen. You prevent the formation of oxides that act as a barrier between the filler and the base metals. This ensures a clean, metallurgically perfect bond. It’s why this process is non-negotiable for joining dissimilar materials like titanium, superalloys, or even ceramics in mission-critical applications.

But creating that perfect void is only half the battle. The way you introduce heat into it changes everything.

The First Choice: Containing the Fire

The most fundamental distinction in furnace design is how it manages heat. This decision dictates your temperature limits, your process, and your costs. It's a choice between two philosophies.

H3: The Hot Wall: A Universe in an Oven

In a hot wall furnace, the heating elements are outside the vacuum chamber (the "retort"). The entire chamber gets hot, and its walls radiate heat to the parts inside.

This design is beautifully simple and efficient for lower-temperature applications, typically below 750°C. Think of it as the pragmatic choice. It's the perfect, cost-effective tool for high-volume aluminum brazing. The psychology here is one of precision: using exactly the tool you need, no more, no less.

H3: The Cold Wall: A Star in a Bottle

In a cold wall furnace, the physics are inverted. The heating elements are inside the vacuum chamber, surrounding the parts directly. The chamber's outer wall is water-cooled, remaining cool to the touch even as the interior rages at over 1200°C.

This is an act of engineering brute force and finesse. It allows for extreme temperatures and rapid cooling, making it the standard for high-strength steels, nickel superalloys, and titanium. It's a more complex and expensive system, but it's the choice you make when the material demands it and failure is not an option.

The Second Choice: Defying Gravity

Once you've decided how to generate heat, you must decide how to orient the part within it. This often seems like a simple logistical choice, but at brazing temperatures, it's a profound engineering problem.

H3: The Horizontal Workhorse: Logic and Versatility

The horizontal furnace is the industry standard. Parts are loaded on trays through a front door, like a conventional oven. It’s versatile, easy to load, and ideal for batch-processing a wide variety of components. For most applications, it is the logical and efficient choice.

H3: The Vertical Ascent: When Geometry is Destiny

Now, reconsider that turbine blade. Or imagine a long, slender driveshaft. At 1200°C, a nickel alloy loses much of its rigidity. It behaves less like steel and more like dense putty.

In a horizontal furnace, gravity would pull on that long part, causing it to sag, warp, and distort. The entire component would be ruined.

For parts that are long, round, or susceptible to distortion, a vertical furnace is the only answer. By loading the part from the top or bottom, gravity holds it in perfect alignment. This design is more complex to install and load, but it acknowledges a simple truth: at high temperatures, physics is unforgiving.

The Engineer's Dilemma: A Matrix of Trade-offs

The choice of a vacuum brazing furnace is never about finding the "best" one. It's about navigating a series of critical trade-offs. You are balancing capability against complexity, and performance against cost.

| Furnace Type | Key Characteristic | Ideal Use Case & Psychology |

|---|---|---|

| Hot Wall | External heating, lower temp (<750°C) | The Pragmatist's Choice: Cost-effective for aluminum; avoids over-engineering. |

| Cold Wall | Internal heating, higher temp (>1200°C) | The No-Compromise Choice: For steels & superalloys where integrity is paramount. |

| Horizontal | Front-loading, versatile | The Workhorse: Efficient for batch processing and diverse parts. |

| Vertical | Top/bottom loading, stable | The Precision Choice: Essential for long or symmetrical parts to defeat gravity-induced distortion. |

From Blueprint to Reality

Understanding these core principles reveals that a furnace is more than a piece of equipment; it is the physical embodiment of a process solution. Whether you need the simple efficiency of a hot wall furnace for aluminum heat exchangers or the distortion-defying architecture of a vertical cold wall system for aerospace components, the design must be purpose-built.

At KINTEK, we specialize in translating these complex process needs into reality. With deep expertise in R&D and manufacturing, we build custom Muffle, Tube, Vacuum, and CVD furnace systems tailored to the unique demands of your materials and geometry. We don't just sell furnaces; we engineer the precise thermal environment your components require for uncompromised integrity.

If your process demands more than an off-the-shelf solution, let's discuss the physics and goals of your application. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Architecture of Purity: Deconstructing the Vacuum Furnace System

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- The Most Important Number in a Vacuum Furnace Isn't Its Temperature

- Beyond the Void: The Hidden Costs of a Perfect Vacuum Furnace

- The Three-Axis Logic: How to Choose a Vacuum Furnace That Works