The Compliance Hurdle: A Roadblock to Innovation?

Imagine this: your team has a groundbreaking idea for a new material. The research is promising, the potential is enormous, but a familiar roadblock appears—the high-temperature processing required. Immediately, the conversation shifts from scientific discovery to regulatory hurdles.

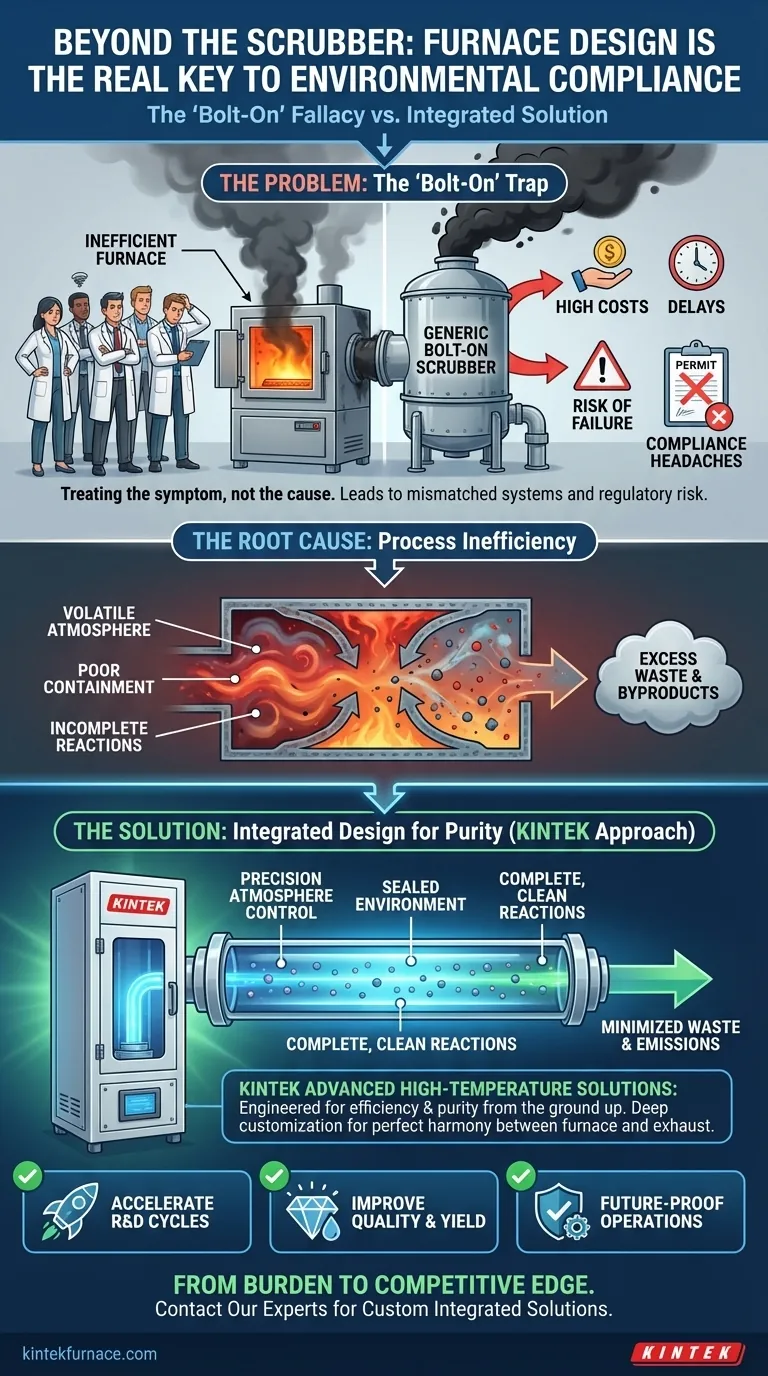

You start picturing complex, expensive exhaust scrubbers, endless paperwork for permits, and the daunting prospect of a system that might not even pass inspection. The project's budget bloats, the timeline stretches, and the initial excitement is replaced by a sense of dread. For many labs and R&D departments, this isn't a hypothetical; it's a recurring reality where environmental compliance feels less like a responsible goal and more like a barrier to progress.

The 'Bolt-On' Fallacy: Why Common Compliance Strategies Fail

Faced with this challenge, most teams follow a predictable path. They procure a high-temperature furnace based on its heating specifications and then try to solve the emissions problem separately. This leads to a few common, yet flawed, approaches:

- The "Bolt-On" Scrubber: A generic, often oversized, waste gas treatment system is purchased and attached to the furnace exhaust. It’s treated as a separate, necessary evil.

- The "Process Tweak": Engineers spend weeks trying to alter reaction parameters to reduce harmful outputs, often working blind without precise atmospheric control, which leads to inconsistent results and compromised product quality.

- The "Safe Route": The team abandons the most promising materials in favor of less effective ones that generate fewer regulated byproducts, stifling innovation from the outset.

These strategies share a common flaw: they treat the symptom, not the cause. The business consequences are significant and measurable. Projects are delayed for months while mismatched systems are integrated. Capital budgets are consumed by inefficient, "one-size-fits-all" treatment units. Worst of all, the risk of a failed emissions test looms, threatening costly fines, operational shutdowns, and damage to your company's reputation.

The Root of the Problem: It’s Not What Comes Out, It’s What Happens Inside

Here is the fundamental shift in thinking that changes everything: the most critical point of environmental control isn't at the exhaust pipe; it's inside the furnace tube itself.

The core issue is process inefficiency. In any high-temperature reaction, the goal is to convert input materials into a desired output product. Unwanted byproducts—the very fumes, particles, and gases that regulations target—are fundamentally a sign of an incomplete or poorly controlled reaction.

When a furnace provides a volatile atmosphere, imprecise temperature uniformity, or poor containment, reactions become messy and inefficient. This inefficiency is what generates the excess waste that you are then forced to treat.

This is precisely why the "bolt-on" strategies fail. Attaching a massive scrubber to an inefficient furnace is like putting a giant bucket under a constantly overflowing sink. You're working tirelessly to manage the mess, instead of simply fixing the leaky faucet. The real solution is to prevent the mess from being created in the first place.

The Integrated Solution: Designing a Furnace for Purity and Compliance

To solve the emissions problem at its source, you need a furnace that is engineered not just as a heater, but as a highly controlled reaction environment. The goal is to create the perfect conditions for your process to run so efficiently that the creation of waste is minimized from the very beginning.

This is the principle behind KINTEK's advanced high-temperature furnace solutions. Our systems are designed from the ground up based on a deep understanding of process chemistry and physics.

- Purity through Atmosphere Control: Our vertical tube furnaces provide an exceptionally sealed and controlled environment. This precision ensures that reactions are clean and complete, maximizing your product yield while inherently minimizing the generation of unwanted particles and waste gases.

- Efficiency by Design: Every KINTEK furnace is engineered for outstanding energy efficiency. By using less energy to achieve and maintain target temperatures, the system's overall carbon footprint is significantly reduced, directly supporting your organization's sustainability goals.

Critically, we recognize that no two processes are alike. For the byproducts that are an unavoidable part of your specific chemistry, our deep customization capability is key. We don't sell you a furnace and leave you to find a scrubber. We work with you to design a fully integrated system, where the furnace and the exhaust treatment work in perfect harmony, tailored specifically to the materials you use. This turns a complex, multi-vendor puzzle into a single, elegant, and guaranteed solution.

From Compliance Burden to Competitive Edge

When your furnace is no longer a source of compliance problems but the foundation of your solution, a remarkable shift occurs. Environmental responsibility ceases to be a burdensome cost center and becomes a strategic advantage.

With an integrated, high-purity system, you can:

- Accelerate R&D Cycles: Confidently explore and scale up processes using advanced materials, knowing your system is built to handle the compliance requirements from day one.

- Improve Product Quality and Yield: The same process control that ensures clean emissions also produces a purer, more consistent end product, reducing defects and saving on raw material costs.

- Future-Proof Your Operations: By investing in a core platform built for both performance and environmental stewardship, you equip your lab to meet not only today's regulations but also the more stringent standards of tomorrow.

By shifting your focus from end-of-pipe fixes to core process control, you transform a persistent challenge into a powerful asset that drives innovation, efficiency, and growth.

Your research is unique, and your compliance strategy should be too. If you're ready to move beyond the "bolt-on" fallacy and build a high-temperature process that is both high-performance and environmentally sound, our team is here to help you design the right integrated system for your specific needs. To explore how a customized furnace solution can resolve your most complex process challenges, Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

Related Articles

- The Controlled Void: How Vacuum Furnaces Forge the Materials of Tomorrow

- Why Your High-Temp Experiments Fail: It’s Not the Heat, It’s the Atmosphere

- The Cascading Logic of Safety: Rethinking the Modern Vacuum Furnace

- The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

- The Physics of Absence: How Vacuum Furnaces Defy the Limits of Heat