It’s the end of a long day in the lab. A critical process is running overnight in the high-temperature furnace. As you turn off the lights, a nagging question surfaces: "Is it truly safe?" You know it has an over-temperature alarm, but is that enough? This quiet uncertainty is a familiar feeling for any lab manager or technician responsible for valuable materials and expensive equipment.

The High Cost of "Good Enough" Safety

This unease is widespread because many laboratories operate with a hidden vulnerability. They rely on a safety approach that feels sufficient on the surface but is dangerously incomplete.

The common strategy is to treat safety as a checkbox during procurement. Does it have an automatic shut-off? Yes. Does it have an alarm? Yes. Problem solved. Operators are then told to "be careful" and rely on these basic alarms to prevent disaster.

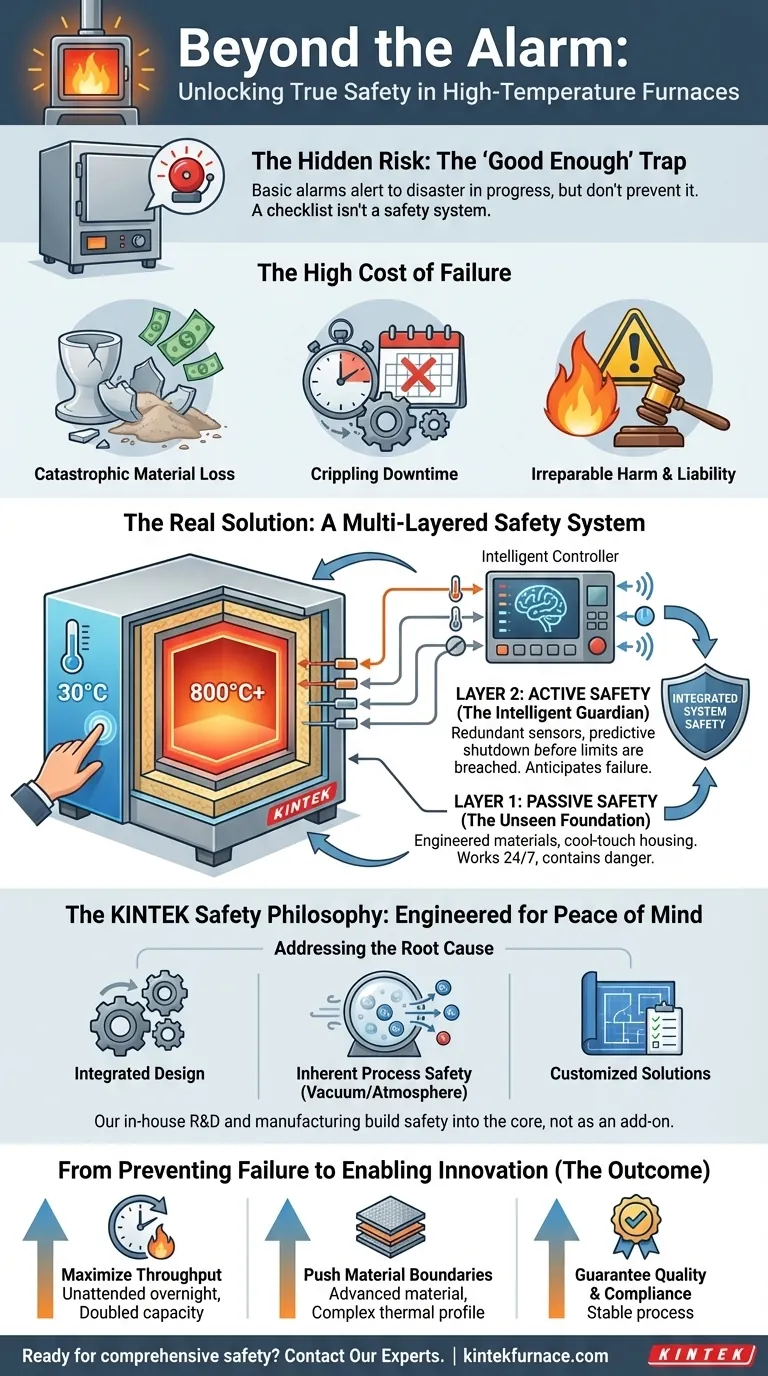

But this approach ignores the harsh reality of what a single failure can mean:

- Catastrophic Material Loss: A single overheating event can destroy an entire batch of custom zirconia crowns, advanced ceramics, or sensitive metal components, instantly wiping out thousands of dollars in materials and labor.

- Crippling Downtime: A damaged furnace isn't a quick fix. It can lead to weeks or even months of downtime, derailing research projects, delaying customer orders, and bringing productivity to a halt.

- Irreparable Harm: In the worst-case scenario, a failure can lead to fire or personal injury, creating significant safety hazards and exposing the entire organization to liability and reputational damage.

Relying on a simple alarm is like relying on a smoke detector to prevent a fire. It alerts you to a disaster already in progress, but it does nothing to stop it from starting in the first place.

The Real Culprit: A Feature Checklist Isn't a Safety System

If basic features aren't enough, what is the real root of the problem? The fundamental issue is viewing furnace safety as a list of independent components rather than as a single, integrated system. True safety is a holistic philosophy, built on two distinct but interconnected layers: passive safety and active safety.

Layer 1: Passive Safety — The Unseen Foundation

Passive safety is the furnace's first line of defense. It’s the safety that works 24/7 without ever being switched on. It's engineered into the very structure and materials of the equipment.

Think of it like the frame and crumple zones of a car. You hope you never need them, but their robust design is critical for containing dangerous forces in a worst-case scenario.

A prime example is a cool-touch double housing. By creating an engineered air gap between the inner heating chamber and the outer casing, the external surface remains safe to the touch (often around 30°C) even when the internal temperature is soaring past 800°C. This isn't just a convenience; it's a fundamental design choice that passively protects your operators from severe burns, every single minute the furnace is running.

Layer 2: Active Safety — The Intelligent Guardian

Active safety systems are the furnace's brain and nervous system. They are the intelligent, automated systems that monitor operations in real-time to prevent conditions from ever becoming dangerous.

This is where a simple feature checklist fails. A basic "over-temperature shut-off" might rely on a single sensor. But what if that sensor fails? An advanced active safety system builds in redundancy. It uses multiple sensors and intelligent controllers that don't just react to a limit but can identify abnormal heating rates or pressure changes, shutting down the system before a limit is ever breached. It anticipates failure instead of just reacting to it.

The common "solutions" fail because they treat these two layers as separate. A poorly constructed furnace (weak passive safety) with a basic alarm (weak active safety) creates multiple points of failure. A truly safe furnace is one where these two systems are designed to work in perfect concert.

Engineered for Peace of Mind: The KINTEK Safety Philosophy

To resolve this fundamental safety gap, you need more than just a furnace; you need a partner who engineers safety into the core of their designs. This is where a deep understanding of thermodynamics, materials science, and control systems becomes non-negotiable.

At KINTEK, our in-house R&D and manufacturing capabilities allow us to build this multi-layered safety philosophy into every furnace we produce. Our solutions are not just an assembly of parts; they are integrated systems designed to provide true peace of mind.

- Addressing the Root Cause: Instead of just adding an alarm, our Muffle, Tube, and Vacuum Furnaces are built with robust, high-integrity materials and standard cool-touch housings (passive safety) that work in concert with precise, multi-stage automatic shut-off systems (active safety).

- Inherent Process Safety: For applications where fire risk is a primary concern, our Vacuum & Atmosphere Furnaces offer an inherently safer environment. By removing oxygen—a key component of combustion—the design itself eliminates the risk, representing the ultimate form of proactive safety.

- Customized for Your Unique Risks: No two labs have identical needs. Our deep customization capability means we don't offer a one-size-fits-all solution. We work with you to understand your specific materials and processes, engineering a safety system—from specialized gas leak detectors to reinforced chamber designs—that is precisely tailored to mitigate your unique risks.

From Preventing Failure to Enabling Innovation

When your team is no longer worried about catastrophic equipment failure, what becomes possible? True operational safety doesn't just prevent disaster; it unlocks new potential.

With the confidence that your furnace is fundamentally safe, you can:

- Maximize Throughput: Run long-term, unattended processes overnight, effectively doubling your lab's capacity without increasing headcount.

- Push Material Boundaries: Experiment with advanced, high-temperature materials and complex thermal profiles, knowing your equipment is built to handle the challenge.

- Guarantee Quality and Compliance: Achieve the process stability and repeatability required for demanding applications, from medical device manufacturing to aerospace components.

Ultimately, a truly safe furnace transforms from a potential liability into a reliable asset that drives your research and production forward.

Your work is too important to be compromised by hidden risks. If you're ready to move beyond a simple safety checklist and implement a comprehensive safety system for your thermal processes, our team is here to help. Let's discuss the unique requirements of your projects and design a solution that protects your people, your materials, and your mission. Contact Our Experts.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

Related Articles

- Cracked Crucibles, Inconsistent Data? The Post-Heating Step You're Missing

- The Invisible Saboteur: Why Your High-Temp Furnace Fails (And How to Stop It)

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- Beyond the Program: Why Your Sintering Fails and How to Guarantee Uniformity

- Why Your High-Temperature Synthesis Results Are Unreliable—And How to Fix It