The Psychology of Purity

At the high temperatures required for material processing, the world becomes hostile. The very air we breathe—a benign mix of nitrogen, oxygen, and trace gases—transforms into a reactive agent, eager to oxidize, contaminate, and compromise the integrity of a carefully engineered material.

This creates a fundamental tension for any materials scientist or engineer. To achieve the desired properties, you must heat the material. But in doing so, you expose its vulnerability.

The solution is not just a furnace, but a precisely controlled environment. The choice of furnace, therefore, comes down to a philosophical question with profound practical consequences: Do you wish to control the atmosphere, or eliminate it entirely?

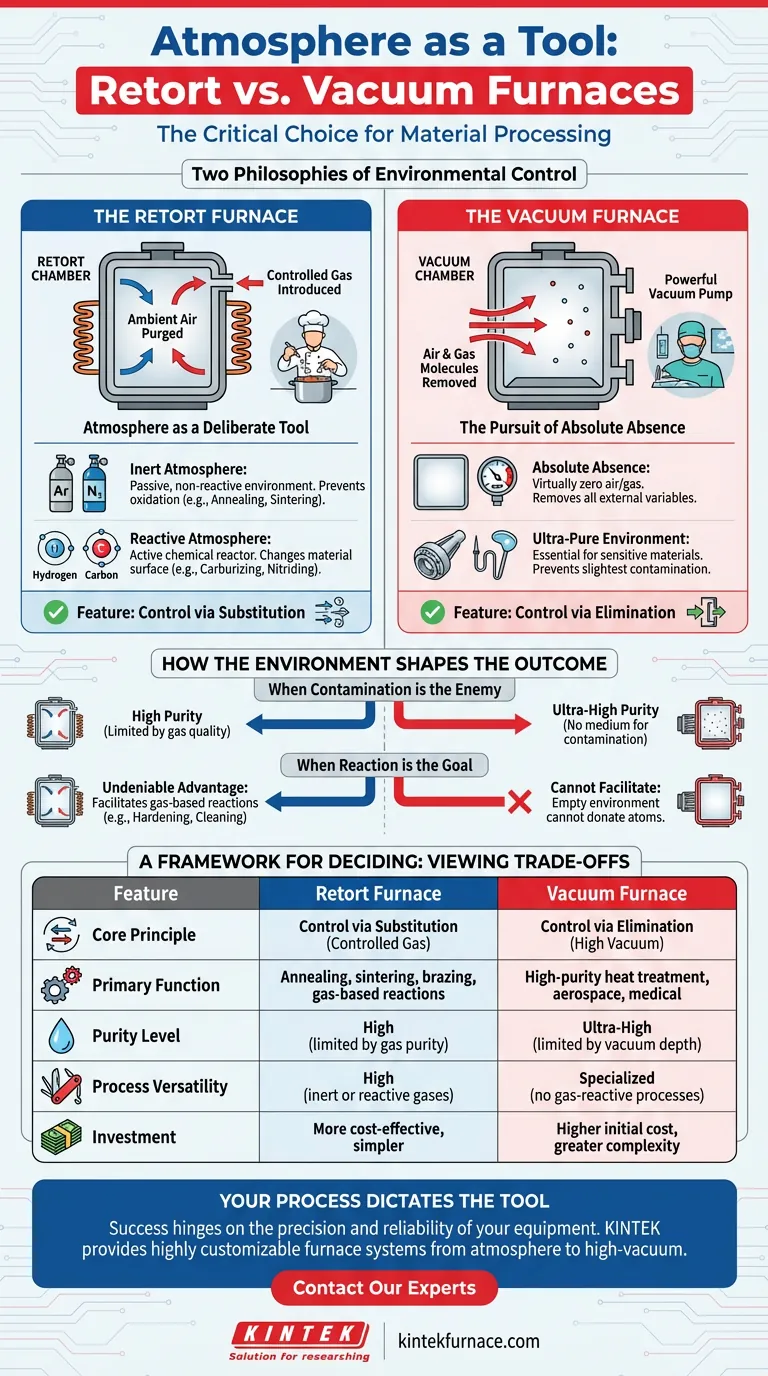

Two Philosophies of Environmental Control

This question leads to two distinct technologies: the retort furnace and the vacuum furnace. They are not merely different types of ovens; they represent two opposing strategies for mastering the environment at a microscopic level.

The Retort Furnace: Atmosphere as a Deliberate Tool

A retort furnace operates on the principle of substitution. It uses a sealed container—the retort—which is placed inside the heating chamber. The ambient air is first purged, then replaced with a specific, high-purity gas.

Think of it like a chef creating a specialized marinade. The atmosphere isn't just a protective blanket; it can be an active ingredient.

- Inert Atmosphere: Using gases like argon or nitrogen, the furnace creates a passive, non-reactive environment to prevent oxidation during processes like annealing or sintering.

- Reactive Atmosphere: By introducing gases like hydrogen or nitrogen, the furnace becomes a chemical reactor. It can actively change the material's surface, enabling processes like hydrogen reduction, carburizing (adding carbon), or nitriding (adding nitrogen).

In this philosophy, the atmosphere is a tool to be wielded with precision.

The Vacuum Furnace: The Pursuit of Absolute Absence

A vacuum furnace embodies a different philosophy: the only safe environment is no environment. Equipped with powerful pumps, it is designed to do one thing with ruthless efficiency: remove virtually every molecule of air and gas from its sealed chamber.

This is the equivalent of a surgeon creating a sterile operating field. The goal is to eliminate all external variables, ensuring that the heat treatment process occurs with no unintended chemical interactions.

This pursuit of absence creates an ultra-pure environment, essential when even the slightest contamination is a critical failure point, particularly for highly reactive metals like titanium or aerospace superalloys.

How the Environment Shapes the Outcome

The choice between a controlled gas and a high vacuum has direct, measurable consequences on the final material.

When Contamination is the Enemy

Both furnaces prevent oxidation, but to different degrees. A retort furnace's purity is limited by the purity of its source gas. For most applications, this is more than sufficient.

A vacuum furnace, however, offers a level of purity that a gas-purged system can never match. By removing the medium for contamination, it protects the most sensitive materials from any atmospheric interaction. This is non-negotiable for medical implants or mission-critical aerospace components.

When Reaction is the Goal

Here, the retort furnace has an undeniable advantage. A vacuum is, by definition, empty. It cannot facilitate processes that rely on a specific gas to donate atoms to a material's surface.

If your goal is to harden a steel surface through nitriding or clean a part through hydrogen reduction, a retort furnace is not just the better choice—it is the only choice.

A Framework for Deciding

Your material's chemistry and your process goals are the only variables that matter. The choice becomes clear when viewed through a simple lens of trade-offs.

| Feature | Retort Furnace | Vacuum Furnace |

|---|---|---|

| Core Principle | Control via Substitution (Controlled Gas) | Control via Elimination (High Vacuum) |

| Primary Function | Annealing, sintering, brazing, gas-based reactions | High-purity heat treatment, aerospace, medical |

| Purity Level | High (limited by gas purity) | Ultra-High (limited by vacuum depth) |

| Process Versatility | High (can use inert or reactive gases) | Specialized (cannot perform gas-reactive processes) |

| Investment | More cost-effective, simpler systems | Higher initial cost, greater complexity |

Your Process Dictates the Tool

Ultimately, the furnace is an instrument to execute a specific material science vision. The decision between a retort and a vacuum system is a strategic one, rooted in the fundamental physics and chemistry of your work.

Whether your process demands the versatile, reactive environment of a muffle or tube furnace, or the absolute purity of a high-vacuum system, success hinges on the precision and reliability of your equipment. At KINTEK, our deep R&D and manufacturing expertise allows us to build highly customizable furnace systems—from vacuum and atmosphere furnaces to advanced CVD platforms—that provide the exact environmental control your work requires.

To ensure your equipment perfectly matches your scientific goals, Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

Related Articles

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- Why Your High-Temp Experiments Fail: It’s Not the Heat, It’s the Atmosphere

- The Architecture of Nothing: Inside the Controlled Universe of a Vacuum Furnace

- Beyond Temperature: Mastering the Invisible Environment in a Tube Furnace