In short, a tube furnace is chosen over a chamber furnace when the process demands precise atmospheric control, protection from contamination, or rapid heating cycles for smaller samples. Its sealed tube design is uniquely suited for creating vacuum or inert gas environments that are impractical or impossible to achieve in a standard chamber furnace.

The decision between a tube and chamber furnace is not about which is "better," but which is architecturally suited for the task. A tube furnace prioritizes atmospheric integrity and speed for smaller volumes, whereas a chamber furnace prioritizes capacity and versatility for processes conducted in air.

The Core Advantage: Atmospheric Control

The single most important reason to select a tube furnace is its ability to tightly control the gaseous environment around a sample. This capability stems directly from its fundamental design.

Sealed Environments for Purity

A tube furnace uses a ceramic, quartz, or metal work tube that is sealed at the ends. This isolates the sample from the outside air and the furnace's heating elements.

This sealed system allows you to introduce modified atmospheres. You can pull a vacuum to remove ambient gases or flow a specific gas, such as nitrogen or argon, to create an inert environment for sensitive materials.

Protection from Contamination

The work tube serves as a protective barrier in two directions. It shields the sample from any particles shed by the furnace insulation or heating elements.

Simultaneously, it protects the furnace itself. If a sample releases corrosive vapors or byproducts during heating, those contaminants are contained within the tube, preventing damage to the more expensive furnace components.

When Sample Size and Speed Matter

Beyond atmospheric control, the physical geometry of a tube furnace offers distinct advantages for specific applications, particularly in research and development settings.

Ideal for Smaller Samples

Tube furnaces are inherently designed for smaller sample sizes. Their limited internal volume is not a flaw but a feature for applications where only small amounts of material are being tested or synthesized.

Rapid Heating and Cooling

Due to their smaller thermal mass compared to a bulky chamber furnace, tube furnaces can heat up and cool down much faster. This allows for quicker process cycles, increasing throughput for rapid testing or experimentation.

Understanding the Trade-offs

Choosing a tube furnace means accepting a clear set of limitations in exchange for its specialized benefits.

Limited Capacity and Throughput

The most obvious trade-off is volume. A tube furnace cannot handle large or bulky parts. It is fundamentally a low-volume, high-precision tool, making it unsuitable for bulk heat treatment or large-scale production.

Constraints on Sample Geometry

Your samples must physically fit inside the tube's diameter. This restricts the shape and size of what can be processed far more than the open box design of a chamber furnace.

Increased System Complexity

Achieving a controlled atmosphere requires additional equipment, such as vacuum pumps, gas flow controllers, and sealing flanges. This adds a layer of operational complexity and cost not present with a simple chamber furnace operating in ambient air.

Making the Right Choice for Your Process

Your specific goal determines the correct tool for the job.

- If your primary focus is high-purity processing or working with air-sensitive materials: A tube furnace is the only viable choice due to its ability to maintain a sealed, controlled atmosphere.

- If your primary focus is heat-treating a large number of parts or bulky items in air: A chamber furnace provides the necessary capacity and simplicity.

- If your primary focus is rapid material testing or developing new processes on small samples: A tube furnace offers the speed and control needed for efficient research and development.

By understanding the fundamental design differences, you can confidently select the furnace that directly serves your processing needs.

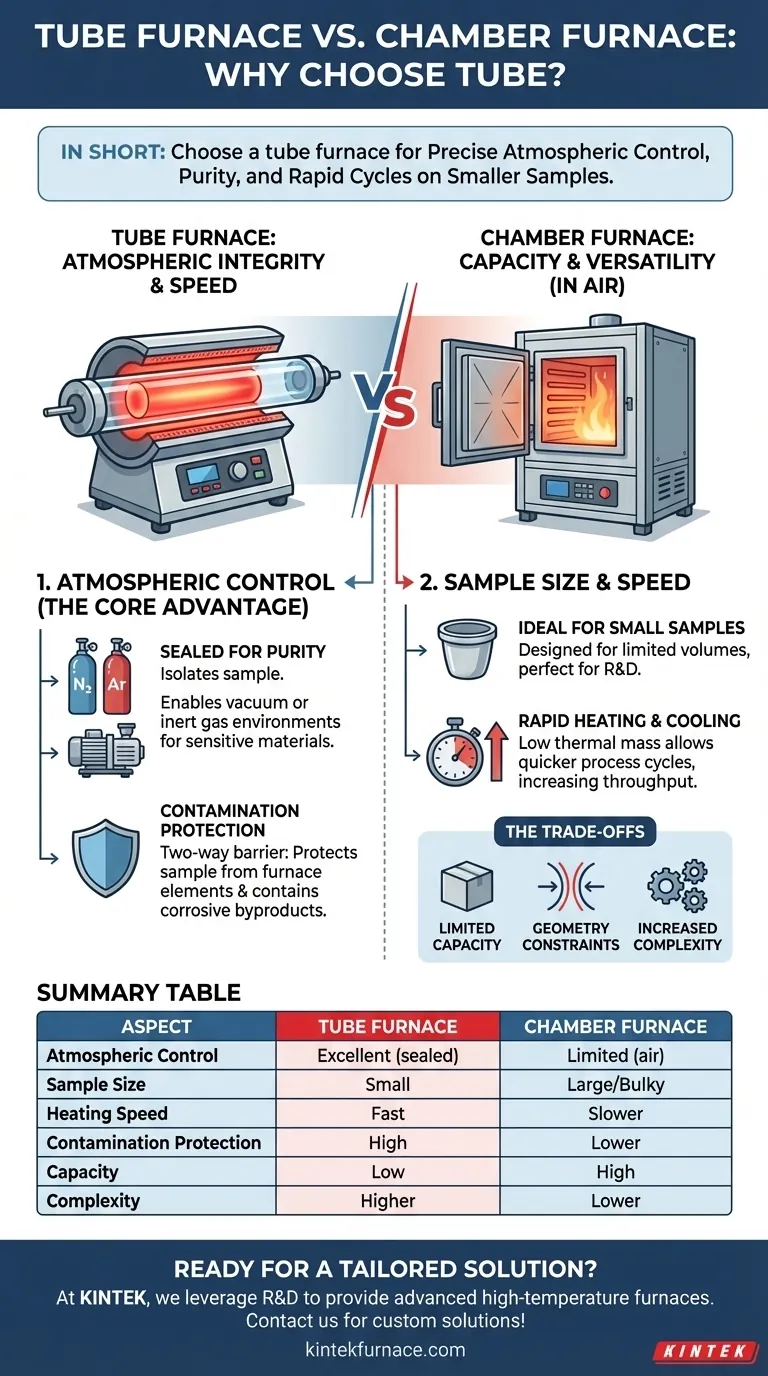

Summary Table:

| Aspect | Tube Furnace | Chamber Furnace |

|---|---|---|

| Atmospheric Control | Excellent (sealed tube for vacuum/inert gas) | Limited (typically open to air) |

| Sample Size | Ideal for small samples | Better for large/bulky items |

| Heating/Cooling Speed | Fast (low thermal mass) | Slower (high thermal mass) |

| Contamination Protection | High (isolates sample) | Lower (exposed to elements) |

| Capacity | Low volume | High volume |

| Complexity | Higher (requires extra equipment) | Lower (simpler operation) |

Ready to enhance your lab's capabilities with a tailored furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces like Tube, Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for atmospheric control, purity, and efficiency. Contact us today to discuss how our solutions can optimize your processes and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab