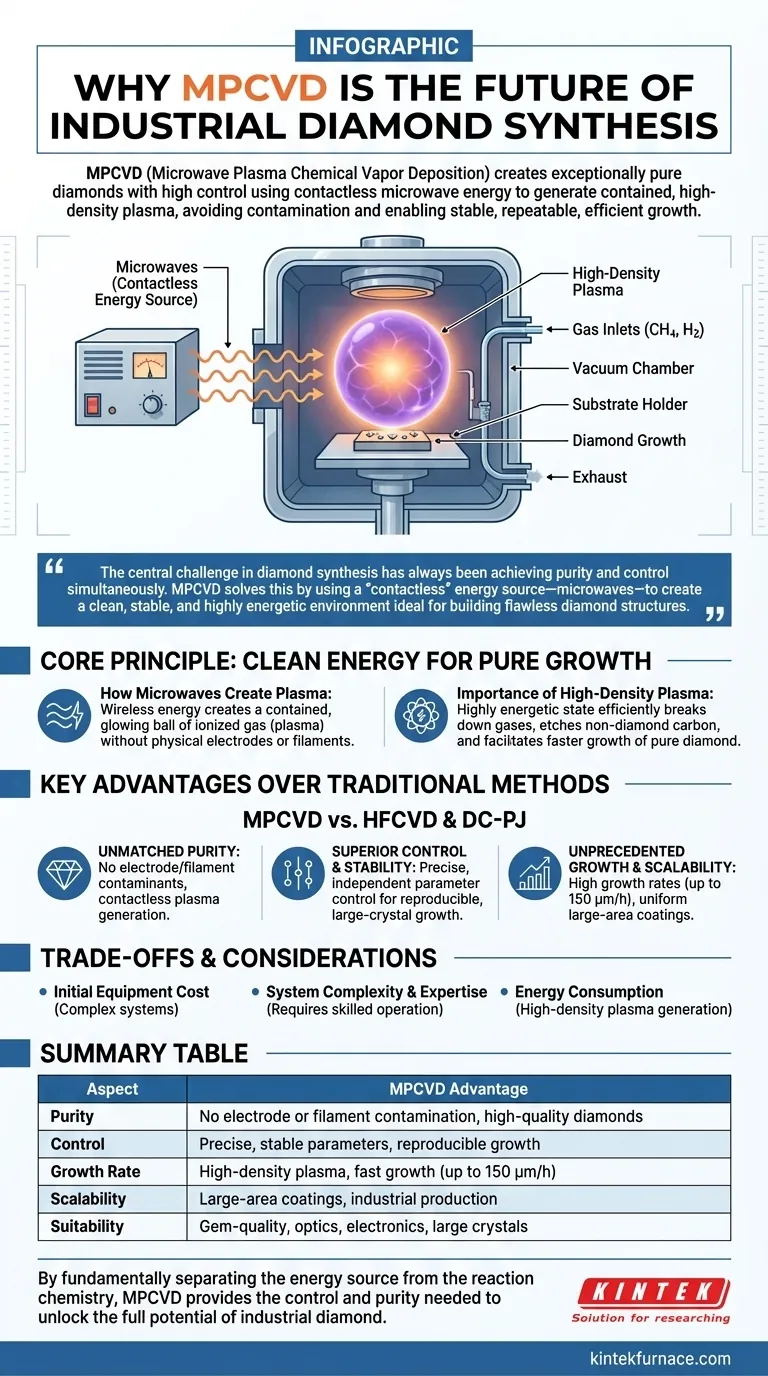

In short, the Microwave Plasma Chemical Vapor Deposition (MPCVD) method is considered the most promising for industrial diamond synthesis because it creates exceptionally pure diamonds with a high degree of control. It uses microwaves to generate a contained, high-density plasma, which avoids the contamination from electrodes or filaments common in older methods, while enabling stable, repeatable, and efficient growth of large, high-quality diamond crystals.

The central challenge in diamond synthesis has always been achieving purity and control simultaneously. MPCVD solves this by using a "contactless" energy source—microwaves—to create a clean, stable, and highly energetic environment ideal for building flawless diamond structures.

The Core Principle of MPCVD: Clean Energy for Pure Growth

To understand why MPCVD is superior, you must first understand how it differs from its predecessors. Its primary innovation lies in how it energizes the carbon-containing gas to deposit diamond.

How Microwaves Create a Contained Plasma

MPCVD systems use microwave energy to excite a mixture of gases (typically methane and hydrogen) inside a vacuum chamber. This intense energy strips electrons from the gas atoms, creating a glowing ball of ionized gas, or plasma.

Crucially, this process requires no physical electrodes or hot filaments inside the chamber near the substrate. The energy is delivered wirelessly, creating a chemically pure reaction environment.

The Importance of High-Density Plasma

The microwave-generated plasma is not only clean but also has a very high density of reactive chemical species. This highly energetic state efficiently breaks down the precursor gases and provides the atomic hydrogen necessary to selectively etch away any non-diamond carbon (like graphite) that forms.

This results in a purer diamond structure and enables significantly higher growth rates compared to less energetic methods.

Key Advantages Over Traditional Methods

When compared directly to older techniques like Hot Filament CVD (HFCVD) or Direct Current Plasma Jet (DC-PJ) CVD, the benefits of MPCVD become clear.

Unmatched Purity: No Contaminants

This is the most significant advantage of MPCVD. Methods like HFCVD rely on heating a metal filament (like tungsten) to very high temperatures, which can degrade and introduce metal contaminants into the diamond film.

Similarly, DC-PJ CVD uses electrodes that can erode over time, polluting the diamond. MPCVD's contactless plasma generation completely eliminates this fundamental source of contamination, leading to higher-quality diamond.

Superior Process Control and Stability

MPCVD allows for precise and independent control over critical parameters like temperature, pressure, and gas composition. Because the plasma is stable and well-contained, conditions can be held constant for long periods.

This stability is essential for achieving reproducible sample quality and for growing large, single-crystal diamonds, which can take hundreds of hours.

Unprecedented Growth and Scalability

The high-density plasma in MPCVD systems facilitates exceptionally high growth rates, reaching up to 150 μm/h in some advanced processes. This is orders of magnitude faster than many standard techniques.

Furthermore, the plasma can be generated over a large and uniform area, allowing for the coating of larger substrates or the simultaneous growth of multiple diamond seeds, making it highly scalable for industrial production.

Understanding the Trade-offs and Considerations

While MPCVD is a superior technology, it is not without its own set of practical considerations. Objectivity requires acknowledging these factors.

Initial Equipment Cost

MPCVD reactors are complex systems involving sophisticated microwave generators, vacuum chambers, cooling systems, and precise gas-handling equipment. This results in a higher initial capital investment compared to simpler HFCVD setups.

System Complexity and Expertise

Operating an MPCVD system effectively requires a higher level of technical expertise. Optimizing the numerous process parameters to achieve specific diamond properties can be a complex task demanding significant process knowledge.

Energy Consumption

Generating a stable, high-density microwave plasma is an energy-intensive process. For large-scale industrial production, the cost of electricity can be a significant operational factor to consider.

Making the Right Choice for Your Goal

Ultimately, the choice of synthesis method depends on the specific requirements of the final application.

- If your primary focus is ultimate purity and performance (e.g., gem-quality, optics, electronics): MPCVD is the undisputed choice due to its contamination-free process and precise control.

- If your primary focus is scalability for producing large, single-crystal diamonds: MPCVD provides the stable, long-duration growth environment necessary for this demanding application.

- If your primary focus is lower-cost polycrystalline coatings where minor impurities are acceptable: While older methods might seem viable, the increasing efficiency and falling operational costs of MPCVD are making it the dominant choice across the board.

By fundamentally separating the energy source from the reaction chemistry, MPCVD provides the control and purity needed to unlock the full potential of industrial diamond.

Summary Table:

| Aspect | MPCVD Advantage |

|---|---|

| Purity | No electrode or filament contamination, leading to high-quality diamonds |

| Control | Precise and stable process parameters for reproducible growth |

| Growth Rate | High-density plasma enables fast growth up to 150 μm/h |

| Scalability | Suitable for large-area coatings and industrial production |

| Suitability | Ideal for gem-quality, optics, electronics, and large crystals |

Unlock the full potential of your diamond synthesis with KINTEK's advanced MPCVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnace systems like CVD/PECVD Systems tailored for laboratories. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior purity, control, and scalability. Contact us today to discuss how our expertise can enhance your industrial diamond production!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth