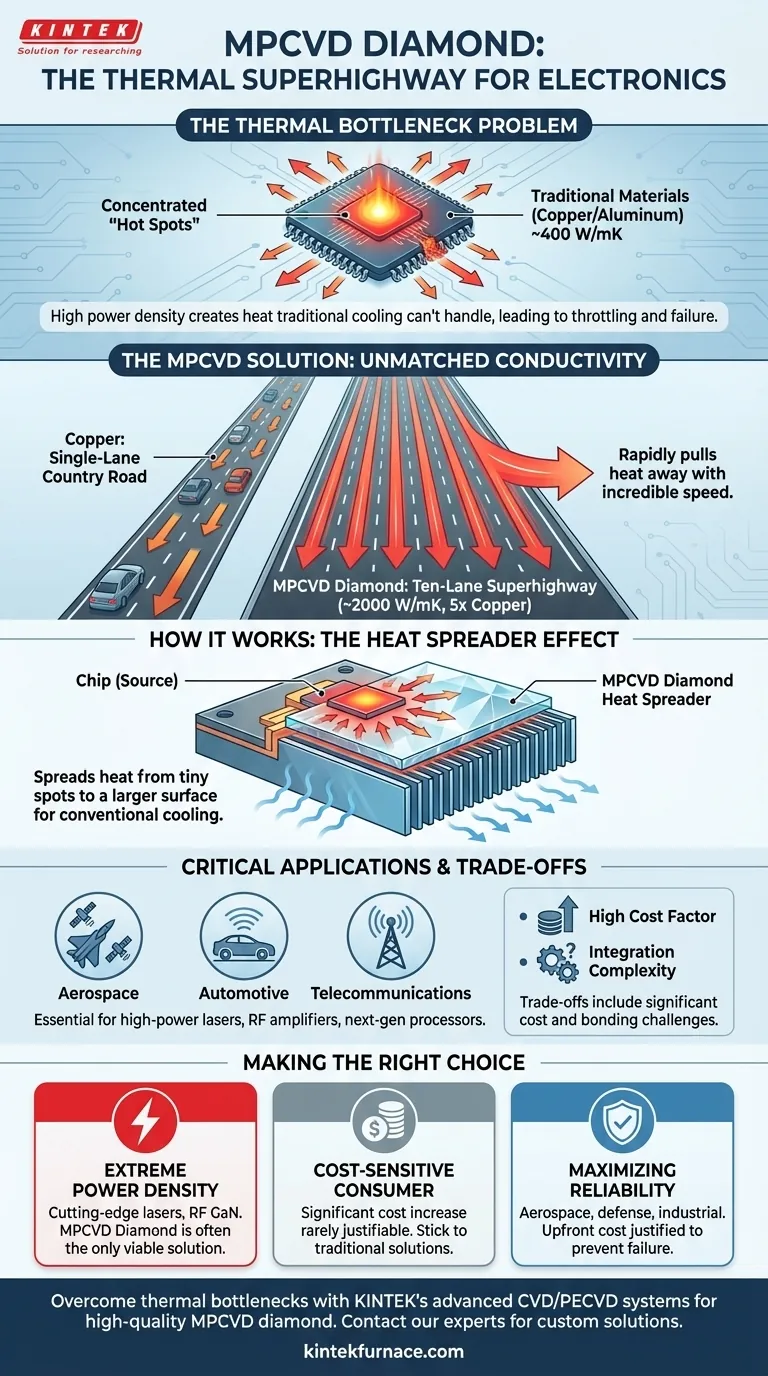

In the world of high-performance electronics, managing heat is the primary barrier to unlocking greater power and speed. Microwave Plasma Chemical Vapor Deposition (MPCVD) is a critical manufacturing process because it enables the growth of single-crystal diamonds, which possess a thermal conductivity far superior to any traditional material. These diamonds act as exceptionally efficient heat spreaders, pulling damaging heat away from sensitive components.

The core challenge in modern electronics isn't a lack of processing power, but the inability to effectively remove the intense heat generated in tiny areas. MPCVD provides the solution by creating a near-perfect material—diamond—that functions as a thermal superhighway, preventing performance bottlenecks and catastrophic failure.

The Core Problem: The Thermal Bottleneck

Modern electronic components are shrinking in size while increasing in power density. This creates concentrated "hot spots" that traditional cooling methods struggle to handle.

Why Traditional Materials Are Hitting a Limit

Materials like copper and aluminum have long been the standard for heat sinks. While effective for general heat dissipation, they lack the thermal conductivity needed to draw heat away from a microscopic hot spot quickly enough.

This creates a thermal traffic jam, causing temperatures to rise rapidly at the source, even if the overall device feels cool.

The Impact of Heat on Performance and Lifespan

Excessive heat is not just a risk; it's a guarantee of poor performance and eventual failure.

High temperatures cause processors to throttle (intentionally slow down), reduce the efficiency and accuracy of components like laser diodes, and accelerate the physical degradation of the device, dramatically shortening its lifespan.

How MPCVD-Grown Diamond Solves the Heat Problem

MPCVD technology directly addresses the thermal bottleneck by creating a material perfectly suited for extreme heat transfer.

Unmatched Thermal Conductivity

The single-crystal diamonds grown via MPCVD have a thermal conductivity approximately 5 times higher than copper. This allows them to pull heat away from a source with incredible speed and efficiency.

Think of it as the difference between a single-lane country road (copper) and a ten-lane superhighway (diamond) for heat transfer.

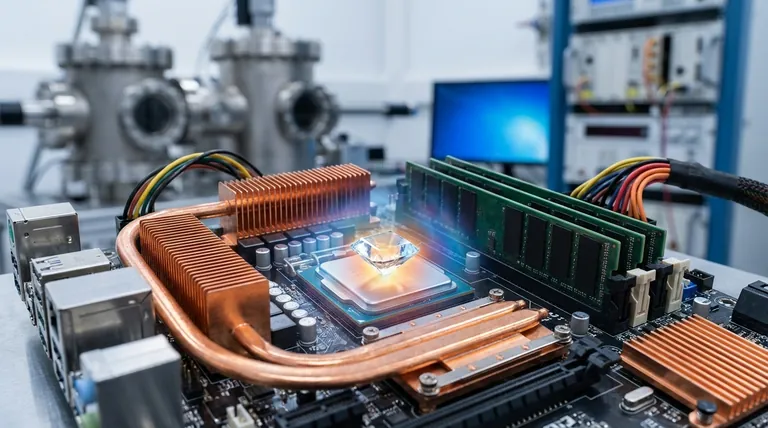

Functioning as a "Heat Spreader"

In most applications, the diamond is not the entire heat sink. Instead, a small diamond chip is bonded directly to the heat-generating component (like a processor die or laser).

This diamond acts as a heat spreader, rapidly pulling heat from the tiny hot spot and distributing it over a much larger surface area. From there, a conventional, larger heat sink made of copper or aluminum can easily dissipate the now-spread-out heat.

Critical Applications

This capability is essential in devices where performance and reliability are non-negotiable.

Key examples include high-power laser diodes, advanced radio-frequency (RF) amplifiers, and next-generation processors used in aerospace, automotive, and telecommunications sectors.

Understanding the Trade-offs

While its thermal performance is unmatched, MPCVD-grown diamond is not a universal replacement for conventional materials. Its application involves specific trade-offs.

The Significant Cost Factor

Manufacturing high-quality, single-crystal diamond is an expensive and energy-intensive process. The cost of a diamond heat spreader is orders of magnitude higher than a similarly sized piece of copper.

This high cost means its use is typically reserved for applications where no other material can meet the thermal requirements.

Integration and Manufacturing Complexity

Bonding a diamond spreader to a silicon chip is a complex engineering challenge. The two materials expand and contract at different rates with temperature changes, which can create stress and lead to failure if not managed perfectly.

This adds another layer of complexity and cost to the manufacturing process.

Making the Right Choice for Your Application

Selecting the right thermal management solution requires balancing performance needs against system-level costs and complexity.

- If your primary focus is managing extreme power density: For cutting-edge laser diodes or RF GaN devices with intense hot spots, an MPCVD diamond heat spreader is often the only viable solution.

- If your primary focus is cost-sensitive consumer products: The significant cost increase for diamond is rarely justifiable, and traditional copper or aluminum solutions remain the standard.

- If your primary focus is maximizing reliability in critical systems: In aerospace, defense, or high-reliability industrial applications, the upfront cost of a diamond spreader is justified by its ability to prevent thermal failure and extend the system's operational life.

By strategically applying this remarkable material, you can overcome the thermal barriers that limit the next generation of electronic performance.

Summary Table:

| Challenge | Traditional Solution | MPCVD Diamond Solution |

|---|---|---|

| High Power Density | Copper/Aluminum Heat Sink | Single-Crystal Diamond Heat Spreader |

| Thermal Conductivity | ~400 W/mK (Copper) | ~2000 W/mK (5x Copper) |

| Key Benefit | Cost-Effective for General Use | Prevents Throttling & Failure in Critical Systems |

| Ideal Application | Consumer Electronics | Aerospace, Telecom, High-Power Lasers |

Overcome thermal bottlenecks in your most demanding applications. KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems essential for producing high-quality MPCVD diamond. Our deep customization capabilities ensure your specific thermal management requirements are met precisely. Contact our experts today to discuss how our technology can enhance your electronic device performance and reliability.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials