Material compatibility is the fundamental principle governing successful sintering. In short, it ensures your furnace can execute the precise heating protocol a specific material requires without damaging the material or the equipment itself. This alignment is what produces strong, dimensionally accurate, and aesthetically pleasing dental restorations.

Choosing a compatible furnace isn't just about whether a material can be heated; it's about guaranteeing the final restoration has the precise strength, color, and fit required for clinical success. A mismatch between the furnace and the material inevitably leads to compromised quality, wasted resources, and costly rework.

The Critical Link Between Material and Furnace

Understanding material compatibility moves beyond a simple temperature check. It involves a holistic view of the entire sintering process, where the furnace's capabilities must perfectly match the material's chemical and physical demands.

Achieving Target Sintering Temperatures

Different dental materials have vastly different sintering windows. Zirconia, for example, typically requires temperatures between 1450°C and 1550°C to achieve its final density and strength.

In contrast, certain non-precious dental alloys require significantly higher temperatures. A furnace that cannot reliably reach and hold the material's specified peak temperature will produce an under-sintered, porous, and clinically weak restoration.

Controlling the Sintering Atmosphere

The atmosphere inside the furnace chamber is as critical as the temperature. Most zirconia restorations are sintered in ambient air.

However, non-precious metals like cobalt-chromium (CoCr) must be sintered in an inert atmosphere, typically using argon gas. This prevents oxidation, which would otherwise ruin the material's structural integrity and biocompatibility. Using a standard zirconia furnace for metals would lead to catastrophic failure of the restoration.

Ensuring Dimensional Accuracy

Sintering causes significant material shrinkage, and managing this is key to a restoration that fits. A compatible furnace provides precise control over the heating and cooling rates.

Ramps that are too fast or too slow can introduce thermal stress, leading to warpage, cracks, or an inaccurate final fit. The furnace must be able to execute the multi-stage time and temperature profile recommended by the material manufacturer with high fidelity.

Preventing Cross-Contamination

Using incompatible materials in the same furnace, even in different cycles, poses a significant risk of cross-contamination. This is especially true when sintering metals and zirconia in the same chamber.

Volatilized metal oxides can deposit on the furnace insulation and heating elements, only to be released during a subsequent zirconia cycle. This contamination can severely discolor a highly aesthetic zirconia crown, rendering it unusable.

Understanding the Risks and Trade-offs

Ignoring material compatibility isn't a shortcut; it's a direct path to failure that carries significant financial and clinical risks.

The Risk of Material Degradation

An improper sintering environment directly compromises the final product. For zirconia, this can manifest as low translucency, chalkiness, or reduced flexural strength, making it prone to fracture. For metals, oxidation can lead to a weak and brittle framework that fails under oral stresses.

The Danger of Furnace Damage

Using a material in a furnace not designed for it can cause permanent damage. The heating elements in most zirconia furnaces (molybdenum disilicide, or MoSi2) are highly susceptible to chemical attack from the gasses released by some materials.

Furthermore, attempting to sinter metals without proper argon flow can damage the furnace chamber and elements, leading to expensive repairs and significant downtime.

The Hidden Cost of Inefficiency

Even if a furnace is technically capable of reaching a temperature, it may not be optimized for it. A furnace struggling at the top of its temperature range will consume more energy and cause its heating elements to degrade much faster, increasing long-term operational costs.

Making the Right Choice for Your Lab

Selecting a furnace should be a deliberate decision based on the primary materials you work with.

- If your primary focus is zirconia restorations: Prioritize a furnace with exceptional temperature accuracy and clean heating elements (like high-purity MoSi2) to ensure predictable aesthetics and strength.

- If your primary focus is non-precious metal frameworks: You must invest in a furnace with robust inert gas management and the ability to safely reach and maintain temperatures well above 1500°C.

- If you run a versatile, multi-material lab: The safest and most efficient strategy is to operate separate, dedicated furnaces for zirconia and metals to eliminate cross-contamination and optimize the workflow for each.

Ultimately, aligning your furnace capabilities with your material requirements is a non-negotiable step toward predictable, high-quality clinical outcomes.

Summary Table:

| Key Aspect | Importance in Sintering |

|---|---|

| Temperature Control | Achieves precise sintering windows (e.g., 1450-1550°C for zirconia) to ensure density and strength. |

| Atmosphere Control | Prevents oxidation with inert gases like argon for metals, avoiding structural damage. |

| Dimensional Accuracy | Manages heating/cooling rates to prevent warpage and ensure proper fit of restorations. |

| Cross-Contamination Prevention | Avoids discoloration and defects by using dedicated furnaces for different materials. |

| Material Degradation Risk | Mismatches lead to weak, porous, or discolored restorations, risking clinical failure. |

| Furnace Damage Risk | Incompatible materials can harm elements (e.g., MoSi2) and chambers, increasing repair costs. |

Upgrade your dental lab's sintering process with KINTEK's precision furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your furnace perfectly matches materials like zirconia or metals, delivering strong, accurate restorations while preventing contamination and damage. Contact us today to discuss how our tailored high-temperature furnace solutions can boost your lab's efficiency and quality—let's achieve clinical success together!

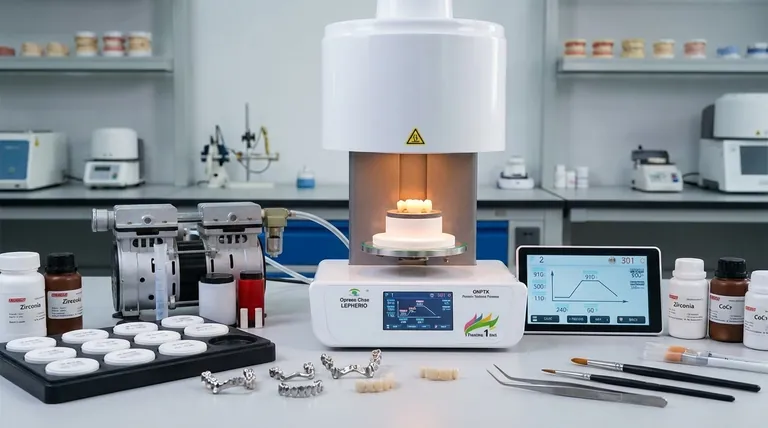

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations