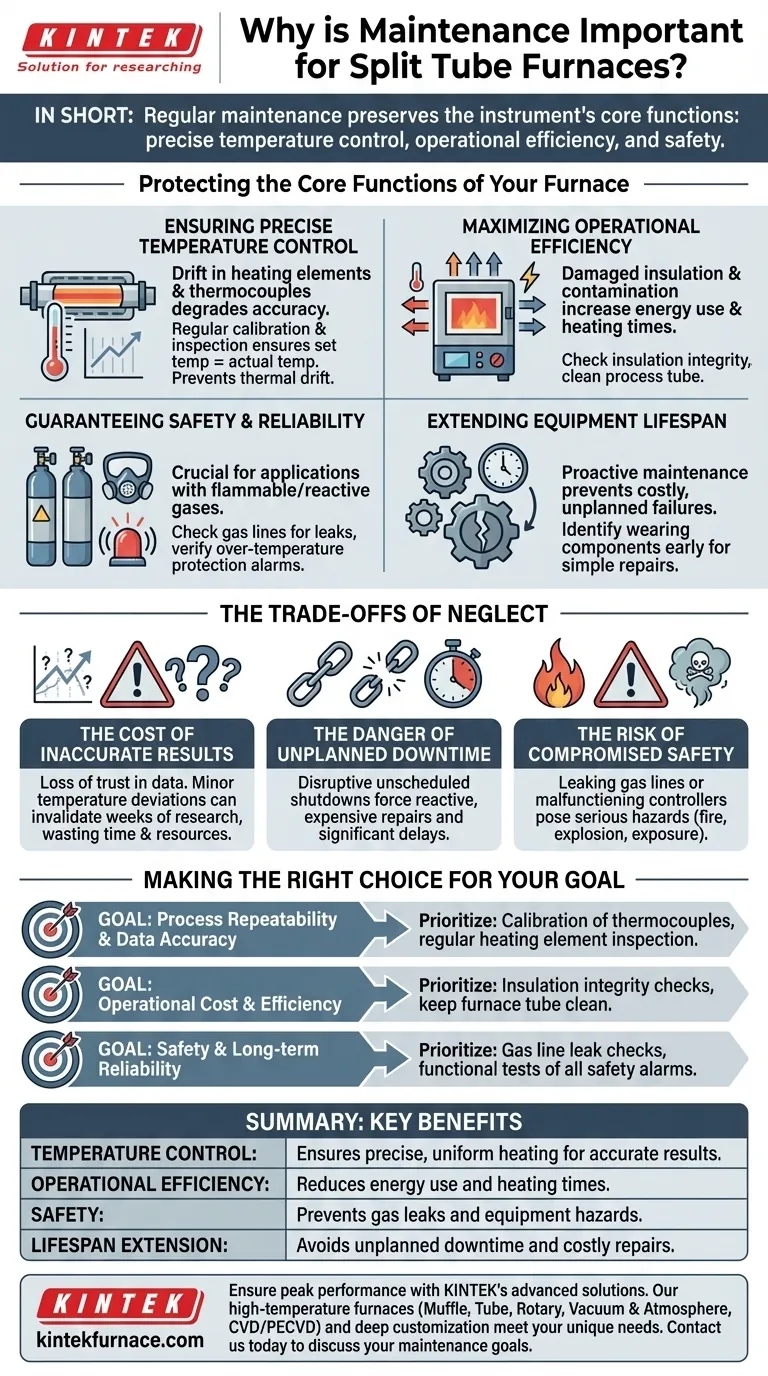

In short, regular maintenance is essential for a split tube furnace because it preserves the instrument's core functions: precise temperature control, operational efficiency, and safety. Neglecting maintenance undermines the very reasons for using such a specialized piece of equipment, leading to inaccurate results, increased operating costs, and significant safety risks.

A split tube furnace is a precision instrument, not just a heater. Proactive maintenance is the only way to ensure it consistently delivers the accurate, repeatable, and safe performance required for high-stakes applications like materials synthesis and chemical vapor deposition.

Protecting the Core Functions of Your Furnace

The value of a split tube furnace lies in its ability to perform specific tasks with high precision. Maintenance is the work required to protect that value.

Ensuring Precise Temperature Control

A split tube furnace's primary function is delivering precise, uniform heat. This capability degrades without maintenance.

Heating elements, often made of resistance wire, can experience thermal drift over time, causing their performance to change. Likewise, thermocouples that measure the temperature can lose accuracy. Regular calibration and inspection are the only ways to counteract this and ensure the set temperature matches the actual temperature inside the tube.

Maximizing Operational Efficiency

Efficiency is measured in both energy and time. Degraded components directly impact both.

Damaged or compressed insulation allows heat to escape, forcing the furnace to consume more energy to maintain its setpoint. Similarly, residue or contamination inside the process tube can act as an insulator, slowing heat transfer to your sample and increasing heating times.

Guaranteeing Safety and Reliability

Many furnace applications, such as chemical vapor deposition (CVD) or pyrolysis, involve flammable or reactive gases.

Regularly checking gas lines and connections for leaks is a non-negotiable safety procedure. Furthermore, built-in safety features like over-temperature protection alarms must be verified to ensure they function correctly, preventing catastrophic failure and protecting personnel.

Extending Equipment Lifespan

Proactive maintenance is an investment that prevents costly, unplanned failures.

Identifying a wearing heating element or a deteriorating section of insulation during a scheduled check allows for a simple, low-cost repair. A sudden failure, by contrast, can cause extensive damage to the furnace chamber, a valuable sample, or connected equipment, resulting in expensive downtime and repairs.

Understanding the Trade-offs of Neglect

Ignoring maintenance isn't a cost-saving measure; it's a deferral of much greater costs down the line. The consequences manifest in three key areas.

The Cost of Inaccurate Results

The most immediate impact of poor maintenance is a loss of trust in your results.

For applications like sintering ceramics or annealing metals, a deviation of just a few degrees can drastically alter the material's final properties. A miscalibrated furnace can invalidate weeks or months of research, leading to wasted time, materials, and resources.

The Danger of Unplanned Downtime

Component failure is never convenient. An unscheduled shutdown during a long-duration test or a critical production run is far more disruptive than a planned maintenance window.

This forces reactive, emergency repairs which are almost always more expensive and lead to significant delays.

The Risk of Compromised Safety

This is the most critical trade-off. A furnace with leaking gas lines or a malfunctioning temperature controller is a serious hazard.

The potential for fire, explosion, or exposure to toxic fumes makes safety-related maintenance an absolute priority. No experiment or production goal is worth compromising the safety of your lab and personnel.

Making the Right Choice for Your Goal

Your maintenance schedule should reflect your primary objectives.

- If your primary focus is process repeatability and data accuracy: Prioritize frequent calibration of thermocouples and regular inspection of heating elements to combat thermal drift.

- If your primary focus is operational cost and efficiency: Emphasize checking insulation integrity and keeping the furnace tube clean to minimize heat loss and ensure efficient heat transfer.

- If your primary focus is safety and long-term reliability: Make gas line integrity checks and functional tests of all safety alarms your non-negotiable first priorities.

Ultimately, consistent maintenance transforms your split tube furnace from a potential liability into a reliable and precise scientific asset.

Summary Table:

| Maintenance Focus | Key Benefits |

|---|---|

| Temperature Control | Ensures precise, uniform heating for accurate results |

| Operational Efficiency | Reduces energy use and heating times |

| Safety | Prevents gas leaks and equipment hazards |

| Lifespan Extension | Avoids unplanned downtime and costly repairs |

Ensure your split tube furnace operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for enhanced precision, safety, and efficiency. Contact us today to discuss how we can support your maintenance goals and deliver reliable performance!

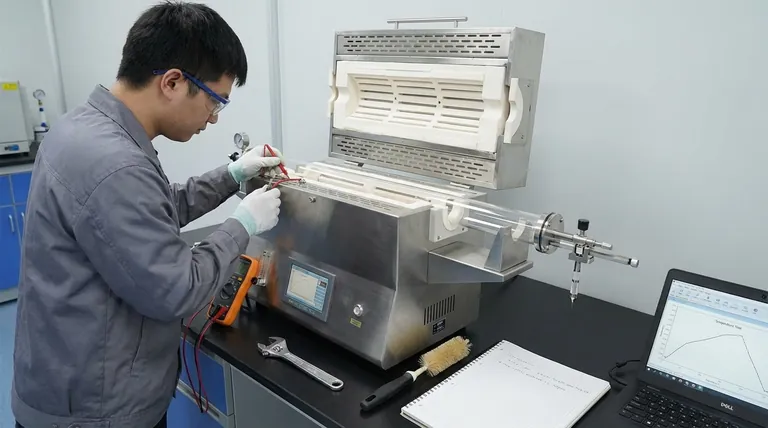

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency