A vacuum annealing furnace is the only viable solution for post-processing titanium parts because it solves the critical conflict between the need for heat and the material's chemical reactivity. While heat is strictly required to release the massive internal stresses caused by Laser Powder Bed Fusion (LPBF), exposing titanium to air at these temperatures would instantly degrade the material.

The core function of the vacuum annealing furnace is to create an oxygen-free thermal environment. This allows you to heat the material enough to release residual stress without triggering oxidation or nitrogen absorption, which would render the titanium brittle and structurally unsound.

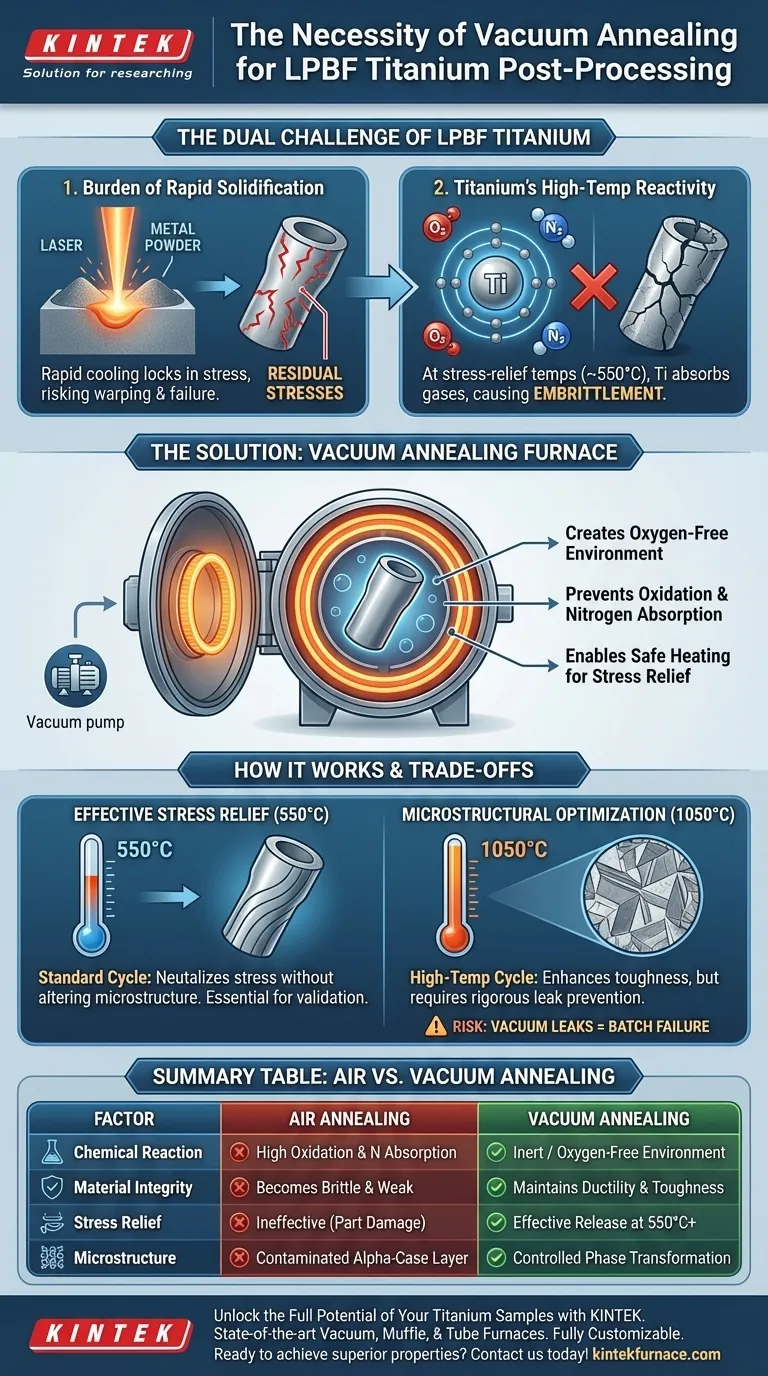

The Dual Challenge of LPBF Titanium

The Burden of Rapid Solidification

Laser Powder Bed Fusion creates parts by melting metal powder with a laser, which then solidifies almost instantly. This rapid cooling cycle locks significant residual stresses into the atomic structure of the material.

The Necessity of Thermal Release

If these internal stresses are not relieved, the part may warp, crack, or fail prematurely under load. To relax the material structure and release this tension, the part must be heated to significant temperatures, typically around 550°C.

Titanium’s High-Temperature Reactivity

Here lies the problem: Titanium alloys are extremely reactive. At the temperatures required for stress relief, titanium acts like a sponge for oxygen and nitrogen found in the atmosphere.

The Consequence of Oxidation

If you were to anneal titanium in a standard air furnace, it would absorb these gases. This leads to embrittlement, a phenomenon where the metal loses its ductility and toughness, making it prone to catastrophic fracture.

How the Vacuum Environment Solves the Problem

Eliminating Chemical Contamination

The vacuum annealing furnace removes the atmosphere from the heating chamber. By processing the samples in a vacuum, you prevent the formation of oxides and the diffusion of nitrogen into the titanium lattice.

Effective Stress Relief

With the threat of oxidation removed, the furnace can safely hold the samples at 550°C for one hour. This thermal cycle effectively releases the accumulated residual stresses from the printing process.

Revealing Intrinsic Properties

Removing residual stress is vital for accurate validation. It ensures that subsequent mechanical testing reveals the intrinsic properties of the material, rather than data skewed by the internal tension left over from manufacturing.

Understanding the Trade-offs and Nuances

Temperature Dependent Outcomes

While 550°C is sufficient for stress relief, higher temperatures (e.g., 1,050°C) are sometimes used to alter the microstructure. At these higher levels, the vacuum facilitates the transformation of brittle martensitic structures into tougher alpha+beta phases, often required for medical implants.

The Risk of Vacuum Leaks

The reliance on a vacuum adds complexity. Even a minor leak or insufficient vacuum level during the heating cycle can ruin the entire batch of parts. The process requires rigorous equipment maintenance to ensure a completely inert environment.

Making the Right Choice for Your Goal

To ensure your commercially pure titanium samples are processed correctly, align your furnace parameters with your specific engineering requirements:

- If your primary focus is Stress Relief: Target a standard cycle of 550°C for one hour to neutralize residual stresses without altering the fundamental microstructure.

- If your primary focus is Microstructural Optimization: Consider higher-temperature cycles (up to 1,050°C) to facilitate phase transformation for enhanced toughness, provided your vacuum equipment can maintain integrity at these extremes.

By isolating the heat treatment in a vacuum, you convert a chemically volatile printed part into a stable, reliable engineering component.

Summary Table:

| Factor | Air Annealing | Vacuum Annealing |

|---|---|---|

| Chemical Reaction | High Oxidation & Nitrogen Absorption | Inert / Oxygen-Free Environment |

| Material Integrity | Becomes Brittle and Weak | Maintains Ductility and Toughness |

| Stress Relief | Ineffective (Part Damage) | Effective Release at 550°C+ |

| Microstructure | Contaminated Alpha-Case Layer | Controlled Phase Transformation |

Unlock the Full Potential of Your Titanium Samples with KINTEK

Don't let oxidation compromise your research or manufacturing quality. KINTEK provides state-of-the-art Vacuum, Muffle, and Tube furnaces specifically designed to handle the rigorous demands of titanium post-processing. Backed by expert R&D and precision manufacturing, our systems are fully customizable to meet your unique thermal cycle and vacuum depth requirements.

Ready to achieve superior material properties? Contact us today to discuss your laboratory's high-temperature needs with our specialists!

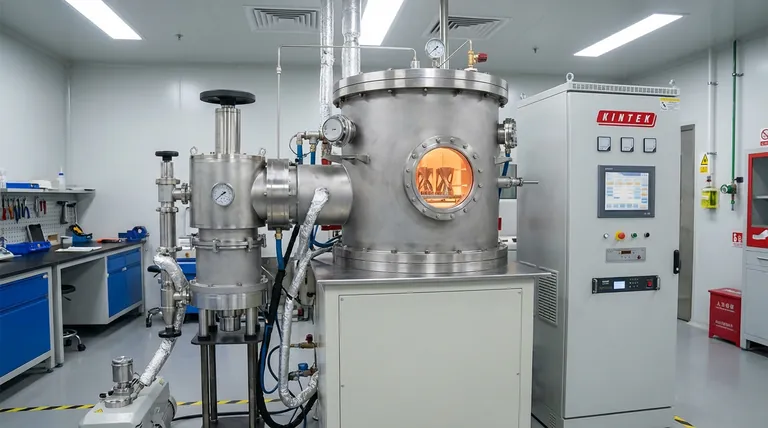

Visual Guide

References

- Yuji Shigeta, Yukiko Ozaki. Use of X-ray CT Imaging to Quantitatively Analyze the Effects of the Pore Morphology on the Tensile Properties of CP-Ti L-PBF Materials. DOI: 10.2355/isijinternational.isijint-2023-431

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why Use a Vacuum Oven for Battery Precursors? Boost Chemical Stability & Grinding Efficiency

- How does a vacuum furnace work to prevent metal oxidation? Achieve Purity in High-Temperature Metal Processing

- What is the primary role of a vacuum resistance heating furnace in the TC4 titanium alloy brazing process?

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- What factors should be considered when selecting a vacuum arc furnace? Optimize Your Material Production with Expert Insights

- Why is degassing important in metal melting, and how does a vacuum help? Achieve Purer, Stronger Metal Alloys

- What is the function of a laboratory vacuum drying oven for lignin-based precursors? Ensure Structural Integrity

- What environmental benefits does a vacuum furnace provide? Boost Sustainability with Clean, Efficient Heat Treatment