At its core, a vacuum furnace prevents oxidation by physically removing the oxygen required for the reaction to occur. By using powerful pumps to create a near-vacuum inside a sealed chamber, the furnace eliminates the atmospheric gases that would normally react with a metal's surface at high temperatures. This allows for processes like heat treatment and brazing to be performed without forming undesirable oxide layers.

The fundamental problem is that heat drastically accelerates the rate at which metals react with oxygen, forming brittle and contaminating oxides. A vacuum furnace solves this not by adding a protective element, but by subtracting the reactant itself—creating an environment so pure that oxidation is chemically impossible.

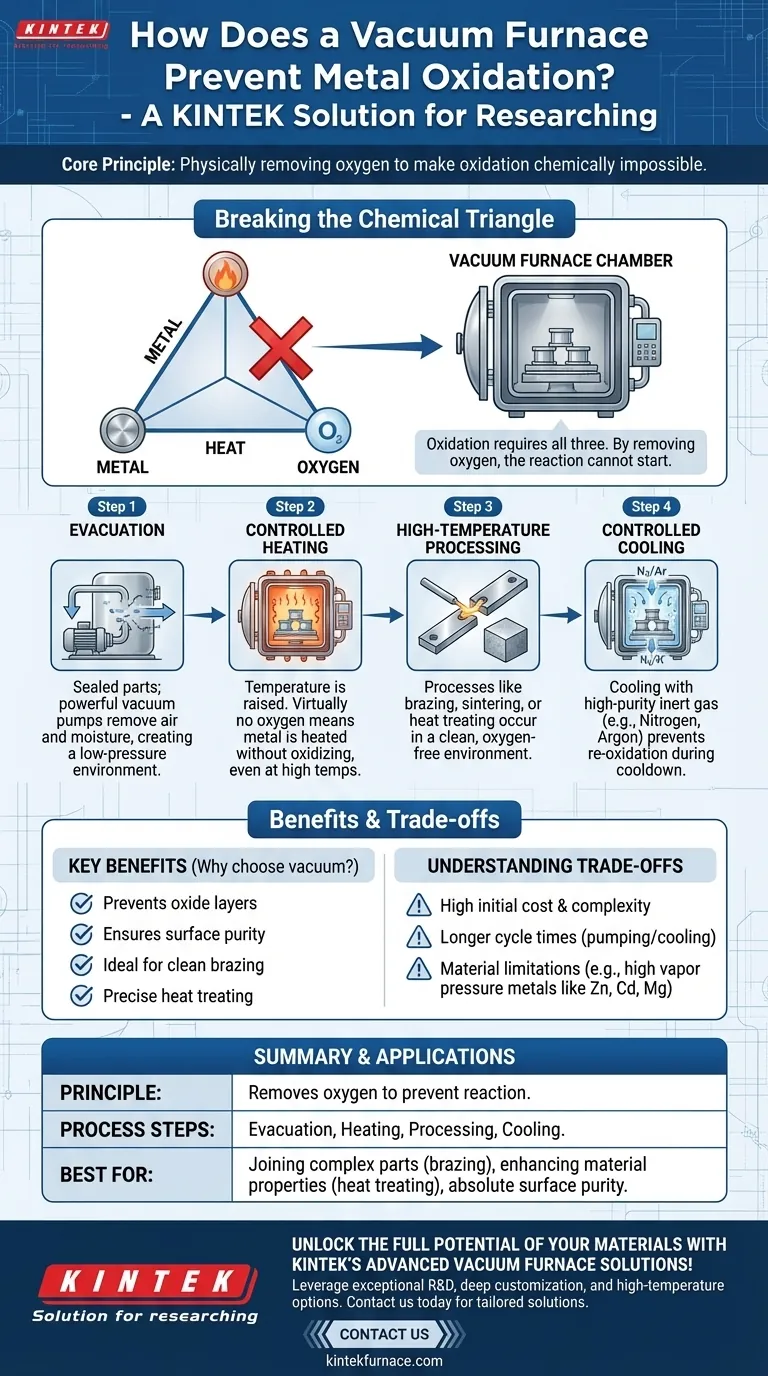

The Fundamental Principle: Removing the Reactant

Oxidation as a Chemical Reaction

All common metal oxidation, like the rusting of iron, is a chemical reaction. It requires three components: the base metal, heat to act as a catalyst, and oxygen to serve as the primary reactant.

When you heat a metal in open air, you provide an abundance of both heat and oxygen, causing a rapid and often detrimental oxide layer to form on the surface.

Breaking the Chemical Triangle

A vacuum furnace works by breaking this chemical triangle. It targets and removes the oxygen component.

By pumping the air out of the chamber, the number of oxygen molecules available to react with the hot metal is reduced by millions of times. This effectively starves the oxidation reaction before it can even begin.

How a Vacuum Furnace Achieves an Oxygen-Free State

Step 1: Evacuation

The process begins by sealing the parts inside the furnace chamber. A series of vacuum pumps then activates to remove the air and any moisture present. This "pumping down" creates an extremely low-pressure environment.

Step 2: Controlled Heating

Once the target vacuum level is reached, heating elements within the furnace raise the temperature of the parts. Because there is virtually no oxygen present, the metal can be heated to very high temperatures (often over 600°F and much higher) without oxidizing.

Step 3: High-Temperature Processing

With the material at temperature in a clean, controlled environment, processes like brazing, sintering, or heat treating can take place. The absence of oxygen ensures that brazing filler flows cleanly and that the material's surface remains uncontaminated.

Step 4: Controlled Cooling

After the process is complete, the parts are cooled in a controlled manner, often by introducing a high-purity inert gas like nitrogen or argon. This cools the parts efficiently without re-introducing reactive oxygen while they are still hot enough to oxidize.

Understanding the Trade-offs

High Initial Cost and Complexity

Vacuum furnaces are sophisticated pieces of equipment. They require robust chambers, complex pumping systems, and precise controls, making them a significant capital investment compared to atmospheric furnaces.

Longer Cycle Times

The need to pump down the chamber to a deep vacuum level before heating and then carefully control the cooling process means that total cycle times are often longer than for conventional oven treatments.

Material Limitations

The vacuum environment is not suitable for all materials. Metals with high vapor pressures, such as zinc, cadmium, or magnesium, can "outgas" or vaporize under a combination of high heat and low pressure, potentially damaging the material and contaminating the furnace.

Making the Right Choice for Your Process

A vacuum furnace offers unparalleled control over the processing environment, but it's essential to align its capabilities with your primary goal.

- If your primary focus is joining complex parts: Vacuum brazing provides exceptionally clean, strong, and flux-free joints, as the vacuum ensures the filler metal wets the surfaces perfectly.

- If your primary focus is enhancing material properties: Vacuum heat treating is ideal for hardening, annealing, or tempering sensitive alloys without introducing surface impurities or discoloration.

- If your primary focus is absolute surface purity: A vacuum furnace is the definitive solution for preventing any atmospheric reaction, ensuring the material's surface remains pristine.

By controlling the environment at a molecular level, a vacuum furnace provides ultimate control over your material's integrity and final properties.

Summary Table:

| Aspect | Description |

|---|---|

| Principle | Removes oxygen to prevent oxidation in a sealed chamber. |

| Process Steps | Evacuation, controlled heating, high-temperature processing, controlled cooling. |

| Key Benefits | Prevents oxide layers, ensures surface purity, ideal for brazing and heat treating. |

| Limitations | High cost, longer cycle times, not suitable for high vapor pressure metals. |

Unlock the full potential of your materials with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for processes such as brazing, sintering, and heat treating. Don't let oxidation compromise your results—contact us today to discuss how our tailored solutions can enhance your lab's efficiency and material integrity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion