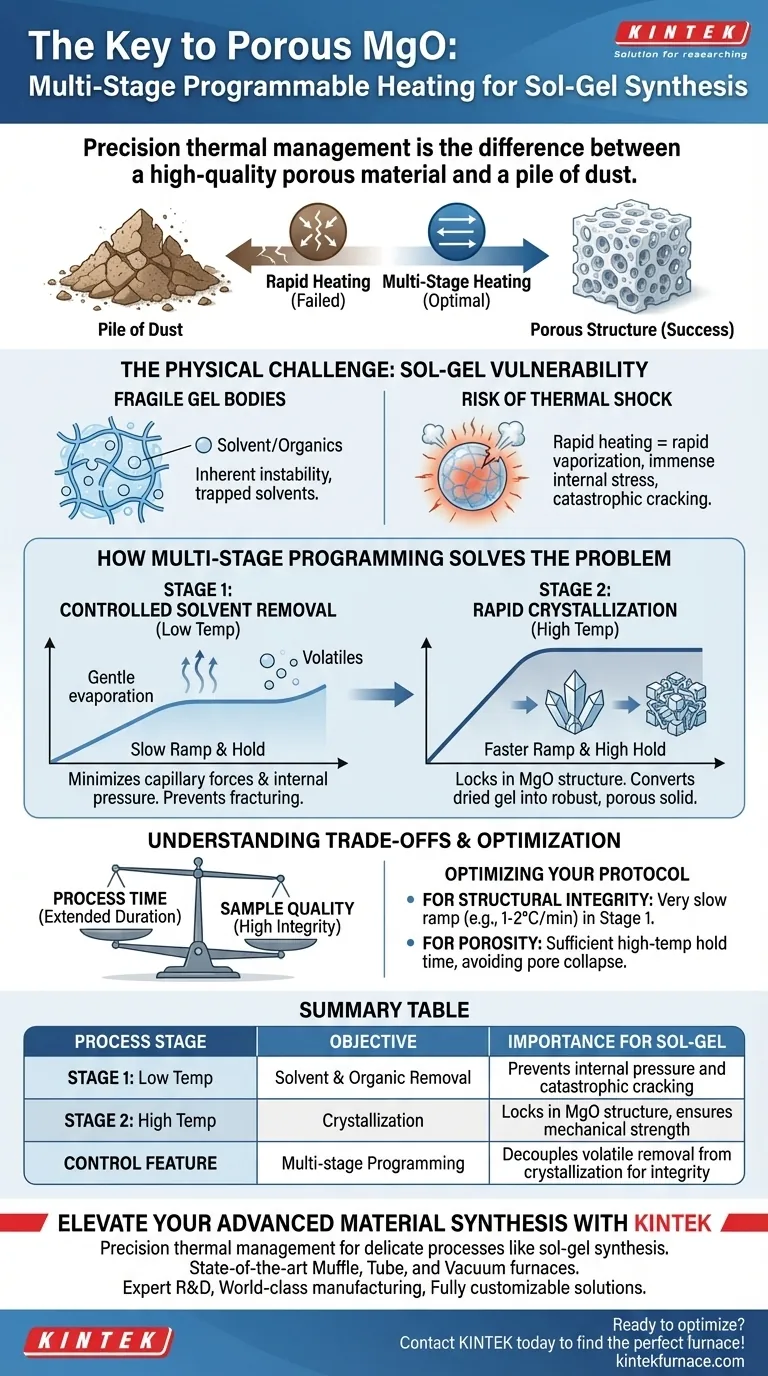

Precision thermal management is the difference between a high-quality porous material and a pile of dust. A muffle furnace with multi-stage programmable heating is necessary because it allows you to decouple the delicate solvent removal process from the high-temperature crystallization phase. This specific control prevents the fragile gel bodies from cracking or disintegrating, ensuring the final magnesium oxide retains its intended porous structure.

The sol-gel method creates a wet, fragile network that is highly sensitive to internal pressure. Multi-stage heating mitigates failure by slowly releasing volatiles before ramping up to the temperatures required for crystallization.

The Physical Challenge of Sol-Gel Processing

The Vulnerability of Gel Bodies

Gel bodies created via the sol-gel method are inherently unstable during the initial stages of processing.

They contain a significant amount of solvent and organic residues trapped within a delicate solid network.

The Risk of Thermal Shock

If these bodies are subjected to a single, rapid heating ramp, the internal liquids vaporize too quickly.

This rapid expansion creates immense internal stress, leading to catastrophic cracking or total disintegration of the sample.

How Multi-Stage Programming Solves the Problem

Stage 1: Controlled Solvent Removal

Programmable heating allows you to set a slow ramp rate and specific holding times at lower temperatures.

This "gentle" phase allows solvents and organics to evaporate gradually.

By removing these volatiles slowly, you minimize capillary forces and internal pressure, preventing the gel from fracturing.

Stage 2: Rapid Crystallization

Once the organic components are safely removed, the furnace can automatically transition to a higher heating rate.

The program then holds the material at a high temperature to facilitate crystallization.

This phase locks in the magnesium oxide structure, converting the dried gel into a robust, porous solid without the risk of collapse.

Understanding the Trade-offs

Process Time vs. Sample Quality

The primary trade-off of using a multi-stage profile is the extended duration of the experiment.

A single-stage ramp is faster, but it almost invariably leads to structural failure in sol-gel derived materials.

Optimization Complexity

Developing the correct program requires trial and error to find the perfect ramp rates for your specific gel composition.

However, once defined, the programmable nature ensures reproducibility, eliminating the variability found in manual adjustments.

Making the Right Choice for Your Goal

Optimizing Your Thermal Protocol

- If your primary focus is Structural Integrity: Program very slow ramp rates (e.g., 1-2°C/min) during the solvent evaporation phase to minimize internal stress.

- If your primary focus is Porosity: Ensure the high-temperature holding time is sufficient to crystallize the skeleton but short enough to prevent pore collapse.

Mastering the thermal profile is the final, critical step in engineering high-performance porous materials.

Summary Table:

| Process Stage | Objective | Importance for Sol-Gel |

|---|---|---|

| Stage 1: Low Temp | Solvent & Organic Removal | Prevents internal pressure and catastrophic cracking |

| Stage 2: High Temp | Crystallization | Locks in the MgO structure and ensures mechanical strength |

| Control Feature | Multi-stage Programming | Decouples volatile removal from crystallization for integrity |

Elevate Your Advanced Material Synthesis with KINTEK

Precision thermal management is the key to unlocking the potential of your porous materials. KINTEK offers state-of-the-art Muffle, Tube, and Vacuum furnace systems specifically designed for delicate processes like sol-gel synthesis.

Backed by expert R&D and world-class manufacturing, our programmable furnaces provide the stability and control needed to ensure your magnesium oxide retains its intended structure without the risk of collapse. Whether you need a standard solution or a fully customizable high-temp furnace tailored to your unique research needs, we are here to support your lab's success.

Ready to optimize your thermal protocol? Contact KINTEK today to find the perfect furnace for your application!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the core function of a laboratory muffle furnace in diatomaceous earth conversion? | KINTEK

- What are the alternative names for a muffle furnace? Discover Key Terms and Design Insights

- How is a muffle furnace utilized in the post-treatment for B-doped SiC nanowires? Ensure High Purity & Integrity

- What are the key differences between a muffle furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- Why is a high-temperature Muffle Furnace required for SiNW manufacturing? Optimize Solid-State Dewetting Processes

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What electrical safety checks should be performed before operating a benchtop furnace? Ensure Safe Operation and Prevent Hazards

- What is the technical significance of the calcination process using a muffle furnace? Optimize TiO2 Nanopowders