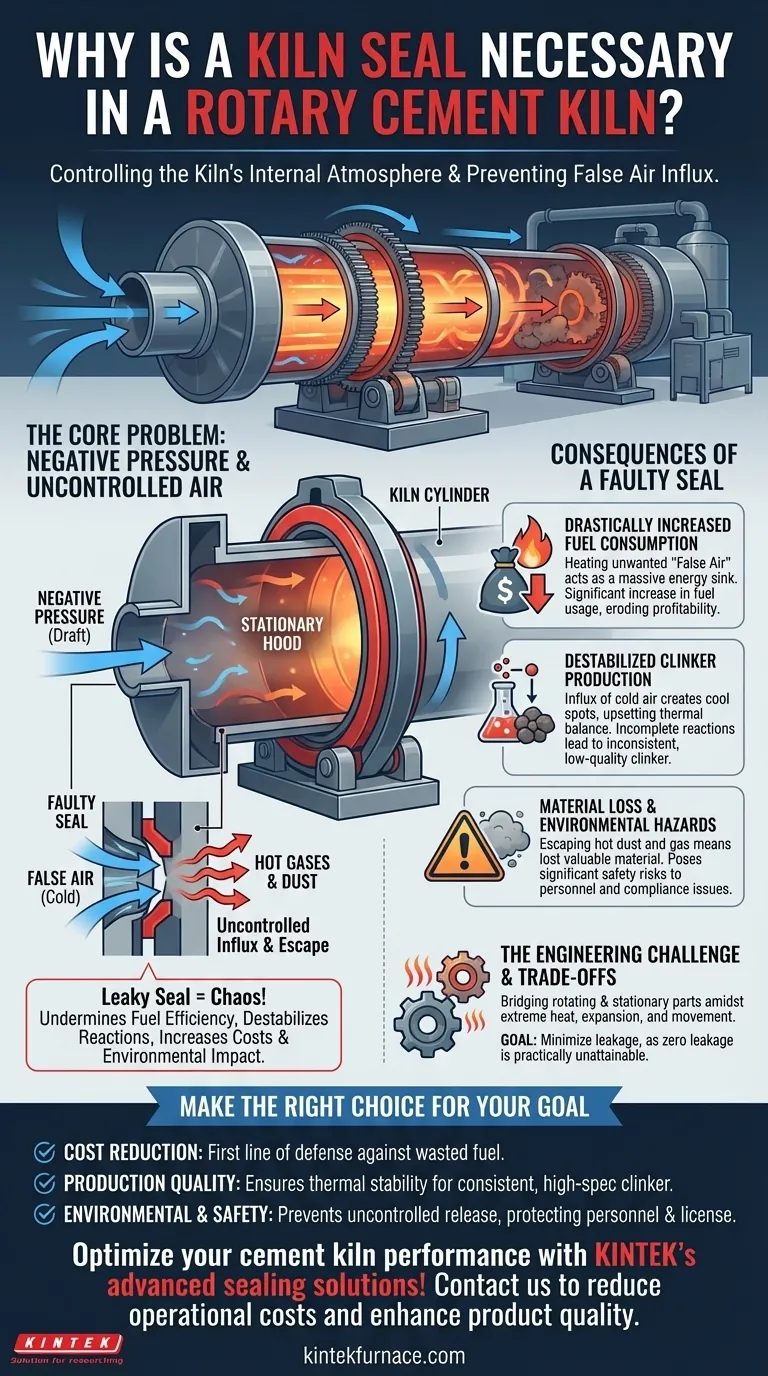

In short, a rotary kiln seal is essential for controlling the kiln's internal atmosphere. It creates a barrier between the rotating kiln cylinder and stationary components, like the inlet and outlet hoods. Because the kiln operates under negative pressure, this seal prevents uncontrolled cold air from leaking into the system and stops hot gases and raw material from escaping out.

A leaky kiln seal introduces chaos into a highly controlled process. This uncontrolled influx of "false air" directly undermines fuel efficiency, destabilizes the chemical reactions that produce clinker, and increases both operational cost and environmental impact.

The Core Problem: Negative Pressure and Uncontrolled Air

A rotary cement kiln is far more than a simple rotating tube; it is a finely tuned combustion device, heat exchanger, and chemical reactor. The kiln seal is the component that protects the integrity of this entire system.

Why the Kiln Environment Must Be Sealed

The kiln system is designed to operate under a slight negative pressure. This draft is necessary to pull hot combustion gases through the kiln and preheater tower, ensuring efficient heat transfer to the raw material. This controlled airflow is a fundamental aspect of the kiln's design.

A faulty or missing seal breaks this control. It creates an open path for "false air"—cold, ambient air—to be sucked directly into the hottest parts of the system, bypassing the proper combustion and heat exchange zones.

The Consequence of an Air Leak

When cold air enters the system, it doesn't contribute to combustion but must still be heated to the extreme process temperatures required for clinkerization (often exceeding 1450°C). This acts as a massive energy sink, forcing the system to burn more fuel just to compensate.

How a Faulty Seal Cripples Kiln Performance

The impact of a poor seal is not minor; it ripples through every aspect of the kiln's operation, turning an efficient process into a wasteful and unstable one.

Drastically Increased Fuel Consumption

This is the most immediate and costly impact. The energy wasted heating unwanted cold air can be enormous. A significant leak can increase fuel consumption by a substantial margin, directly eroding the plant's profitability. It negates the efficiency gains from systems designed to recycle hot air from the clinker cooler.

Destabilized Clinker Production

The formation of cement clinker is a precise chemical reaction that demands a stable, high-temperature thermal profile. An influx of cold air can create cool spots, upsetting the delicate temperature balance. This leads to incomplete chemical reactions, resulting in lower-quality, inconsistent clinker that can fail to meet specifications.

Material Loss and Environmental Hazards

A seal works both ways. While it stops cold air from getting in, it also prevents hot dust and gas from escaping. A leak at the kiln outlet can lead to a continuous loss of valuable, partially processed material. Furthermore, this escaping hot dust poses a significant safety hazard to personnel and an environmental compliance risk.

Understanding the Trade-offs: The Challenge of Sealing a Rotating System

Sealing a rotary kiln is a significant engineering challenge, which is why seal performance is a constant focus in plant maintenance.

The Mechanical Dilemma

The seal must bridge the gap between the massive, rotating kiln shell and the stationary hood. It must remain effective despite extreme heat, thermal expansion and contraction of the kiln shell, and the inevitable minor misalignments and movements of the rotating body.

No Seal is Perfect

Various seal designs exist, from simple labyrinth seals to more complex graphite or spring-actuated systems. However, no seal creates a truly perfect, hermetic barrier. The goal is always to minimize leakage to a manageable and acceptable level, as zero leakage is practically unattainable in such a harsh and dynamic environment.

Making the Right Choice for Your Goal

Viewing the kiln seal as a simple maintenance item is a mistake. It should be seen as a primary lever for controlling the core functions of the plant.

- If your primary focus is cost reduction: A high-performance seal is your first line of defense against wasted fuel, which is a primary operational cost in any cement plant.

- If your primary focus is production quality: An effective seal provides the thermal stability required to produce consistent, high-quality clinker, reducing the risk of off-spec product.

- If your primary focus is environmental compliance and safety: A properly functioning seal prevents the uncontrolled release of hot dust and gases, protecting personnel, the environment, and the plant's operating license.

Ultimately, the kiln seal is not just a component; it is a critical enabler of a safe, efficient, and profitable cement manufacturing process.

Summary Table:

| Impact Area | Consequence of Faulty Seal | Benefit of Effective Seal |

|---|---|---|

| Fuel Efficiency | Increased consumption due to false air | Reduced fuel costs and energy waste |

| Production Quality | Unstable clinker formation and lower quality | Consistent, high-spec clinker output |

| Environmental & Safety | Material loss and emission hazards | Improved compliance and personnel safety |

| Operational Cost | Higher maintenance and downtime | Enhanced profitability and reliability |

Optimize your cement kiln performance with KINTEK's advanced sealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnace systems like Rotary Furnaces tailored for cement plants. Our deep customization capabilities ensure precise sealing to minimize air leaks, boost fuel efficiency, and stabilize clinker production. Contact us today to discuss how our solutions can reduce your operational costs and enhance product quality!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality

- What distinguishes direct from indirect rotary kilns? Choose the Right Kiln for Your Material

- How do vibrational feeder specifications impact rotary kiln efficiency? Optimize Your Lab's Material Flow & Stability

- What are some common processes carried out in rotary kilns? Unlock Efficient Material Transformation Solutions

- What supporting equipment is needed for a rotary kiln system? Essential Components for Efficient Thermal Processing