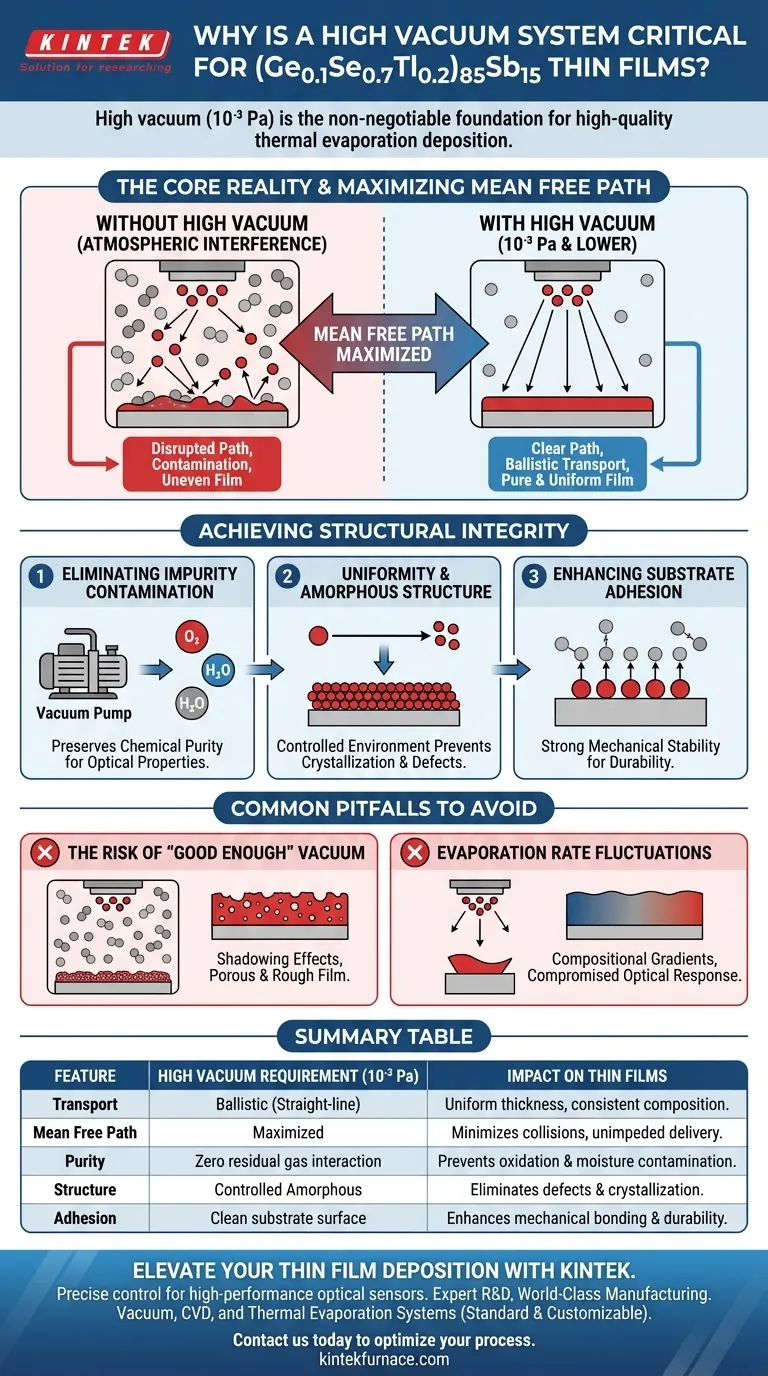

High vacuum is the non-negotiable foundation for depositing high-quality (Ge0.1Se0.7Tl0.2)85Sb15 thin films. Specifically, maintaining a pressure of 10⁻³ Pa is required to remove residual gas molecules that would otherwise obstruct the path of the vaporized material. This "clear path" is the only way to ensure the atoms deposit in a straight line, creating the uniform, amorphous, and pure structure required for sensitive optical sensor applications.

The Core Reality Without a high-vacuum environment, atmospheric interference disrupts the deposition path, leading to contaminated, uneven films. The vacuum extends the mean free path of vaporized atoms, ensuring precise, impurity-free delivery essential for high-performance optical devices.

Maximizing the Mean Free Path

To understand why vacuum is critical, you must understand the behavior of atoms in flight.

Reducing Molecular Collisions

In a low-vacuum or atmospheric environment, the chamber is crowded with residual gas molecules. When you vaporize the source material, the atoms collide with these gas molecules almost immediately.

A high vacuum of 10⁻³ Pa drastically reduces the density of these background gases. This minimizes the frequency of collisions, allowing the vaporized material to travel unimpeded.

Ensuring Ballistic Transport

When collisions are minimized, the vaporized atoms travel in a straight-line path from the source to the substrate.

This phenomenon, known as ballistic transport, is critical for this specific quaternary alloy. It prevents the scattering of atoms, ensuring that the flux of material arriving at the substrate is directional and consistent.

Achieving Structural Integrity

For (Ge0.1Se0.7Tl0.2)85Sb15 films to function in optical sensors, they must meet strict structural standards that only high vacuum can provide.

Eliminating Impurity Contamination

Residual gases are not just obstacles; they are contaminants. Oxygen or moisture present in the chamber can react with the film during growth.

High vacuum ensures that no impurity contamination degrades the material. This preserves the chemical purity of the (Ge0.1Se0.7Tl0.2)85Sb15 composition, which is vital for maintaining its specific optical properties.

Uniformity and Amorphous Structure

The straight-line deposition enabled by high vacuum results in a film with uniform thickness across the substrate.

Furthermore, this controlled environment supports the formation of a distinct amorphous structure. Any deviation in pressure could lead to localized crystallization or defects that ruin the film's performance in sensor applications.

Enhancing Substrate Adhesion

Films deposited under high vacuum exhibit strong adhesion to the substrate.

Because the atoms arrive with sufficient energy and without interference from adsorbed gas layers on the substrate surface, they bond more effectively. This mechanical stability is crucial for the durability of the final device.

Common Pitfalls to Avoid

While high vacuum is essential, it introduces specific operational challenges that must be managed.

The Risk of "Good Enough" Vacuum

It is tempting to start deposition before reaching the full 10⁻³ Pa threshold to save time.

However, even a slight increase in pressure decreases the mean free path. This leads to "shadowing" effects where the film becomes porous or rough rather than dense and smooth.

Evaporation Rate Fluctuations

While vacuum protects the path, it does not automatically control the source.

If the vacuum pressure fluctuates during the process, the evaporation rate can become unstable. This results in compositional gradients within the film, altering the ratio of Ge, Se, Tl, and Sb, which compromises the device's optical response.

Making the Right Choice for Your Goal

Achieving the perfect film requires aligning your vacuum strategy with your end goals.

- If your primary focus is Optical Sensor Performance: Strict adherence to the 10⁻³ Pa (or lower) limit is mandatory to guarantee high purity and the correct amorphous structure.

- If your primary focus is Process Repeatability: Ensure your pumping system can consistently reach base pressure to prevent batch-to-batch variations in thickness and adhesion.

Controlling the vacuum level is the single most effective variable for transitioning from a rough coating to a precision optical component.

Summary Table:

| Feature | High Vacuum Requirement (10⁻³ Pa) | Impact on (Ge0.1Se0.7Tl0.2)85Sb15 Thin Films |

|---|---|---|

| Transport | Ballistic (Straight-line) | Ensures uniform thickness and consistent alloy composition. |

| Mean Free Path | Maximized | Minimizes molecular collisions for unimpeded atom delivery. |

| Purity | Zero residual gas interaction | Prevents oxidation and moisture contamination in optical layers. |

| Structure | Controlled Amorphous | Eliminates localized crystallization and structural defects. |

| Adhesion | Clean substrate surface | Enhances mechanical bonding and long-term device durability. |

Elevate Your Thin Film Deposition with KINTEK

Precise control over high-vacuum environments is the difference between a failed coating and a high-performance optical sensor. At KINTEK, we understand the rigorous demands of complex alloy deposition like (Ge0.1Se0.7Tl0.2)85Sb15.

Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum, CVD, and thermal evaporation systems specifically engineered for laboratory and industrial precision. Whether you need a standard setup or a customizable system tailored to your unique research needs, our team is ready to support your technical goals.

Ready to optimize your deposition process? Contact us today to discuss how our high-temp furnace and vacuum solutions can bring unmatched purity and repeatability to your lab.

Visual Guide

References

- A. M. Ismail, E.G. El-Metwally. Insight on the optoelectronic properties of novel quaternary Ge–Se–Tl–Sb non-crystalline glassy alloy films for optical fiber sensing devices. DOI: 10.1140/epjp/s13360-024-05012-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the function of a non-consumable vacuum arc furnace? Achieve Purity in FeSiBPCCuNb Alloy Synthesis

- How does a gas pressure furnace facilitate the densification of Si3N4–SiC–MoSi2? Achieving Near-Theoretical Density

- Why is precise temperature control in a vacuum debinding furnace critical? Ensure Integrity of Porous Tungsten

- What industrial applications benefit from vacuum arc furnaces? Essential for Aerospace, Medical, and Energy

- What are the two primary configurations of vacuum furnaces? Hot Wall vs. Cold Wall Explained

- How does a vacuum annealing furnace modify the bond coat? Optimize TBC Systems for Superior Thermal Protection

- What is the purpose of a vacuum furnace? Achieve Superior Material Quality and Purity

- What role does a vacuum drying oven play in Ru-Mo2C@CN post-treatment? Preserve Morphology & Catalytic Activity