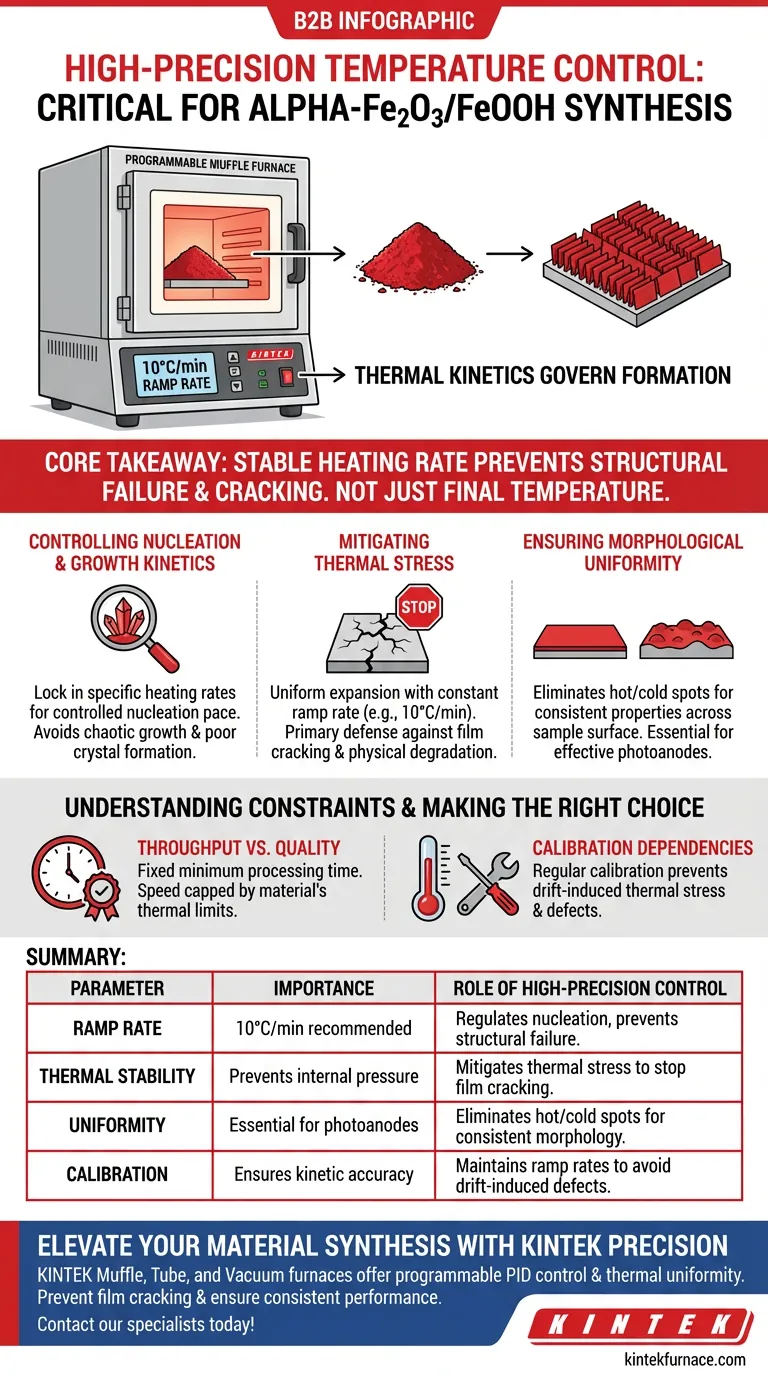

High-precision temperature control is mandatory for synthesizing alpha-Fe2O3/FeOOH because the formation of these nanosheets is strictly governed by thermal kinetics. Specifically, you must use a programmable furnace to maintain a stable ramp rate, such as 10 degrees Celsius per minute, up to 450 degrees Celsius to prevent structural failure.

Core Takeaway The physical integrity of alpha-Fe2O3/FeOOH samples is dictated by the stability of the heating rate, not just the final temperature. Without precise program control to regulate nucleation and mitigate thermal stress, the material will suffer from film cracking and morphological inconsistencies, rendering the photoanode ineffective.

The Critical Role of Thermal Stability

The transformation of precursors into alpha-Fe2O3/FeOOH is a delicate process where the heating history determines the material's final architecture.

Controlling Nucleation and Growth Kinetics

The transition from raw material to structured nanosheets relies on specific reaction kinetics.

A high-precision furnace allows you to lock in a specific heating rate, ensuring that nucleation occurs at a controlled pace.

If the temperature fluctuates or rises too quickly, the growth mechanism becomes chaotic, leading to poor crystal formation.

Mitigating Thermal Stress

Materials expand as they heat, and rapid or uneven heating creates internal pressure.

A constant, programmed ramp rate (e.g., 10°C/min) allows the material to expand uniformly.

This stability is the primary defense against film cracking, which physically degrades the sample and interrupts the continuity required for electronic applications.

Ensuring Morphological Uniformity

For a photoanode to function correctly, the material properties must be consistent across the entire sample surface.

Precision heating eliminates "hot spots" or "cold spots" that result in uneven growth.

This creates a uniformly distributed material, which is essential for consistent electrochemical performance.

Understanding the Constraints

While high-precision equipment is necessary for quality, it imposes specific operational constraints that must be managed.

Throughput vs. Quality

Strict adherence to a ramp rate (such as 10°C/min) dictates a fixed minimum processing time.

You cannot accelerate the manufacturing process by simply increasing the heating power without risking morphological non-uniformity.

Production speed is effectively capped by the physical limits of the material's ability to withstand thermal stress.

Equipment Calibration Dependencies

The definition of "high precision" relies entirely on the calibration of the furnace's thermocouples and controller.

A furnace that drifts even slightly from the programmed ramp rate can reintroduce the thermal stress you are trying to avoid.

Regular calibration is as critical as the hardware itself to maintain the required kinetic control.

Making the Right Choice for Your Goal

To ensure successful synthesis, align your equipment capabilities with your specific material requirements.

- If your primary focus is Structural Integrity: Prioritize a furnace with programmable PID control to strictly enforce the 10°C/min ramp rate, as this is the primary variable preventing film cracking.

- If your primary focus is Electrochemical Performance: Ensure the furnace provides exceptional thermal uniformity within the chamber to guarantee the nanosheets are distributed evenly across the photoanode surface.

Mastering the ramp rate is the difference between a high-performance photoanode and a cracked, unusable sample.

Summary Table:

| Parameter | Importance in Synthesis | Role of High-Precision Control |

|---|---|---|

| Ramp Rate | 10°C/min recommended | Regulates nucleation and prevents structural failure. |

| Thermal Stability | Prevents internal pressure | Mitigates thermal stress to stop film cracking. |

| Uniformity | Essential for photoanodes | Eliminates hot/cold spots for consistent sample morphology. |

| Calibration | Ensures kinetic accuracy | Maintains programmed ramp rates to avoid drift-induced defects. |

Elevate Your Material Synthesis with KINTEK Precision

Don’t let thermal stress compromise your alpha-Fe2O3/FeOOH research. KINTEK provides high-precision Muffle, Tube, and Vacuum furnaces specifically designed to meet the rigorous thermal kinetics of advanced material synthesis. Backed by expert R&D and manufacturing, our systems offer the programmable PID control and thermal uniformity required to prevent film cracking and ensure consistent photoanode performance.

Ready to achieve superior morphological uniformity? Contact our laboratory specialists today to discuss our customizable high-temperature solutions for your unique lab needs.

Visual Guide

References

- Wenyao Zhang, Changqing Zhu. Deposition of FeOOH Layer on Ultrathin Hematite Nanoflakes to Promote Photoelectrochemical Water Splitting. DOI: 10.3390/mi15030387

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the purpose of using an industrial-grade oven for segmented drying? Optimize Electrode Integrity & Adhesion

- How are high-temperature furnaces and precision balances used for alloy oxidation kinetics? Expert Analysis

- What is the purpose of adding metal oxides such as copper oxide (CuO) in RAB? Enhancing Air Brazing & Ceramic Bonding

- What role does an electric heating industrial furnace play in biomass pyrolysis? Unlock High-Quality Biochar Yields

- What is the primary function of an electric furnace in PBG melting? Expert Guide to Thermal Homogeneity

- What is the role of a 5% N2 + 95% H2 mixture in plasma nitriding? Enhance Fatigue Strength and Eliminate White Layers

- Why are high-precision constant temperature drying ovens required for potassium-sulfur batteries? Ensure Data Integrity

- What is the function of a ball mill in the raw material pretreatment stage for the szaibelyite vacuum thermal reduction process?