In short, tubular furnaces are valued in academic and research settings for their ability to provide an exceptionally precise, uniform, and atmospherically controlled heating environment. This control is fundamental for the repeatability and accuracy required in scientific experiments, from creating new materials to testing their thermal properties.

The core value of a tubular furnace isn't just that it gets hot, but that it creates a highly isolated and stable environment. By containing a sample within a tube, researchers gain precise control over two critical variables: temperature distribution and atmospheric composition, which is essential for credible and repeatable results.

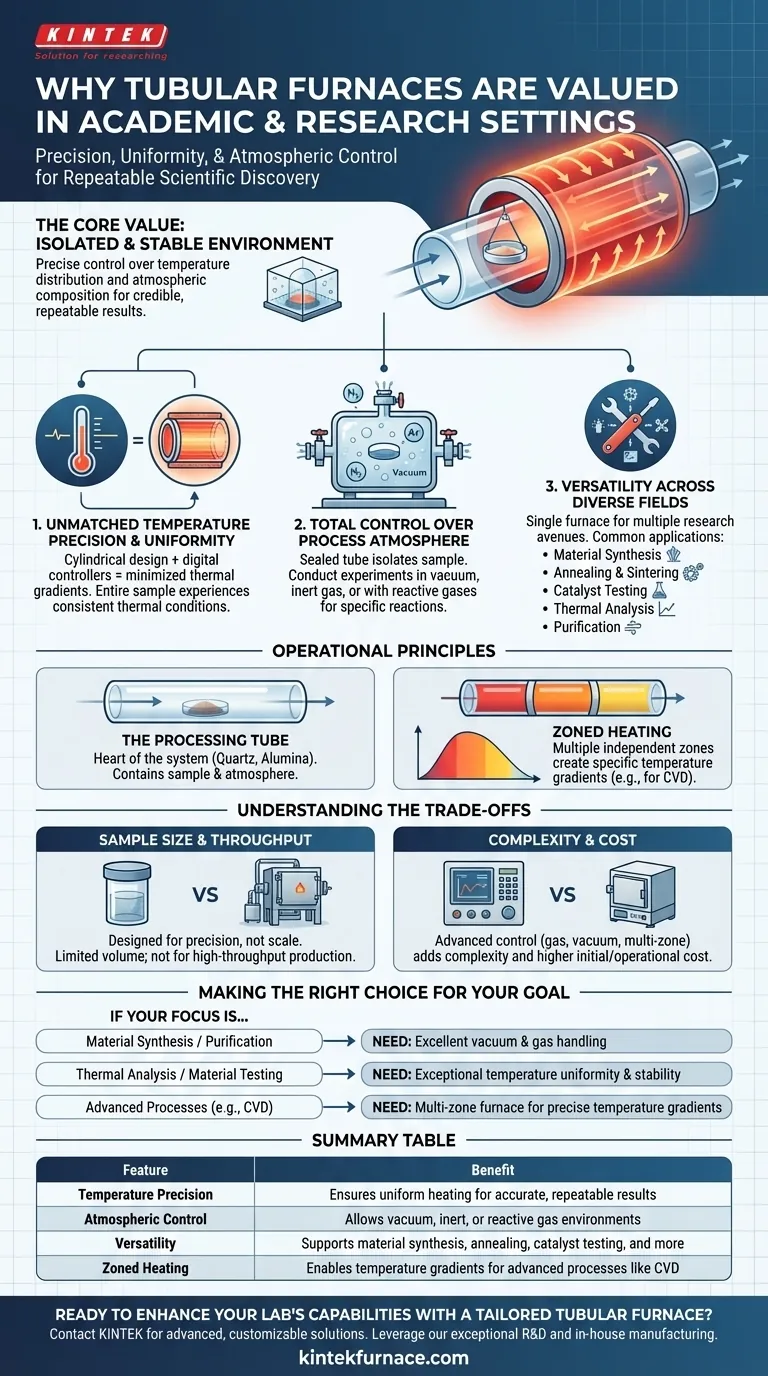

The Core Pillars of a Furnace's Value

To understand why these furnaces are staples in laboratories, we must look at the specific capabilities that enable advanced research. These pillars are precision, atmospheric control, and versatility.

Unmatched Temperature Precision and Uniformity

The cylindrical design of a tubular furnace is inherently advantageous. Heating elements surround the process tube, delivering heat energy evenly to the sample from all sides.

This design minimizes temperature gradients, ensuring the entire sample experiences the same thermal conditions. Combined with modern digital controllers, researchers can maintain specific temperature setpoints with high accuracy, which is critical for processes sensitive to the slightest thermal fluctuation.

Total Control Over the Process Atmosphere

Perhaps the most significant advantage is the ability to control the atmosphere. The sealed process tube isolates the sample from the ambient air, preventing unwanted oxidation or contamination.

This allows experiments to be conducted under a vacuum, in an inert gas (like argon or nitrogen) to protect the material, or with a reactive gas to facilitate a specific chemical reaction. This capability is impossible to achieve in a standard chamber furnace.

Versatility Across Diverse Research Fields

Because of this precision and atmospheric control, a single tubular furnace can be used for a vast range of applications. This makes it a cost-effective and space-efficient tool for labs exploring multiple research avenues.

Common applications include:

- Material Synthesis: Growing crystals or creating new compounds.

- Annealing & Sintering: Heat-treating materials to alter their microstructure and properties.

- Catalyst Testing: Evaluating the performance of catalysts under specific thermal and atmospheric conditions.

- Thermal Analysis: Studying how materials behave when subjected to heat.

- Purification: Removing impurities from compounds through sublimation.

Understanding the Operational Principles

The value of a tubular furnace comes from how its components work together to create a controlled experimental vessel.

The Role of the Processing Tube

The tube itself is the heart of the system. Typically made of quartz, alumina, or another ceramic, it contains both the sample and the desired atmosphere. The choice of tube material depends on the maximum required temperature and the chemical reactivity of the process.

The Power of Zoned Heating

More advanced tubular furnaces feature multiple, independently controlled heating zones along the length of the tube. This allows a researcher to create a specific temperature gradient. This is essential for sophisticated processes like chemical vapor deposition (CVD), where different temperature zones are required to transport and deposit material.

Understanding the Trade-offs

While incredibly powerful, tubular furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Sample Size and Throughput

Tubular furnaces are designed for precision, not scale. The diameter of the process tube inherently limits the size and volume of the sample. While perfect for research-scale experiments and material discovery, they are not suitable for high-throughput industrial production, where larger batch or chamber furnaces are preferred.

Complexity and Cost

The high degree of control comes with added complexity. Systems with advanced gas handling, vacuum pumps, and multi-zone controllers require more operator training and represent a higher initial investment than a simple box furnace. The cost of process tubes, which are consumable, also adds to the operational expense.

Making the Right Choice for Your Goal

The specific features you prioritize in a tubular furnace should align directly with your experimental needs.

- If your primary focus is material synthesis or purification: You need a system with excellent vacuum and gas handling capabilities to ensure precise atmospheric control.

- If your primary focus is thermal analysis or material testing: You need exceptional temperature uniformity and stability to guarantee that your results are valid and repeatable.

- If your primary focus is advanced processes like vapor deposition: You need a multi-zone furnace to create and manage a precise temperature gradient along the tube.

Ultimately, the tubular furnace provides the controlled, repeatable environment that is the bedrock of credible scientific discovery.

Summary Table:

| Feature | Benefit |

|---|---|

| Temperature Precision | Ensures uniform heating for accurate, repeatable results |

| Atmospheric Control | Allows vacuum, inert, or reactive gas environments |

| Versatility | Supports material synthesis, annealing, catalyst testing, and more |

| Zoned Heating | Enables temperature gradients for advanced processes like CVD |

Ready to enhance your lab's capabilities with a tailored tubular furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can support your research with reliable, high-performance equipment!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis