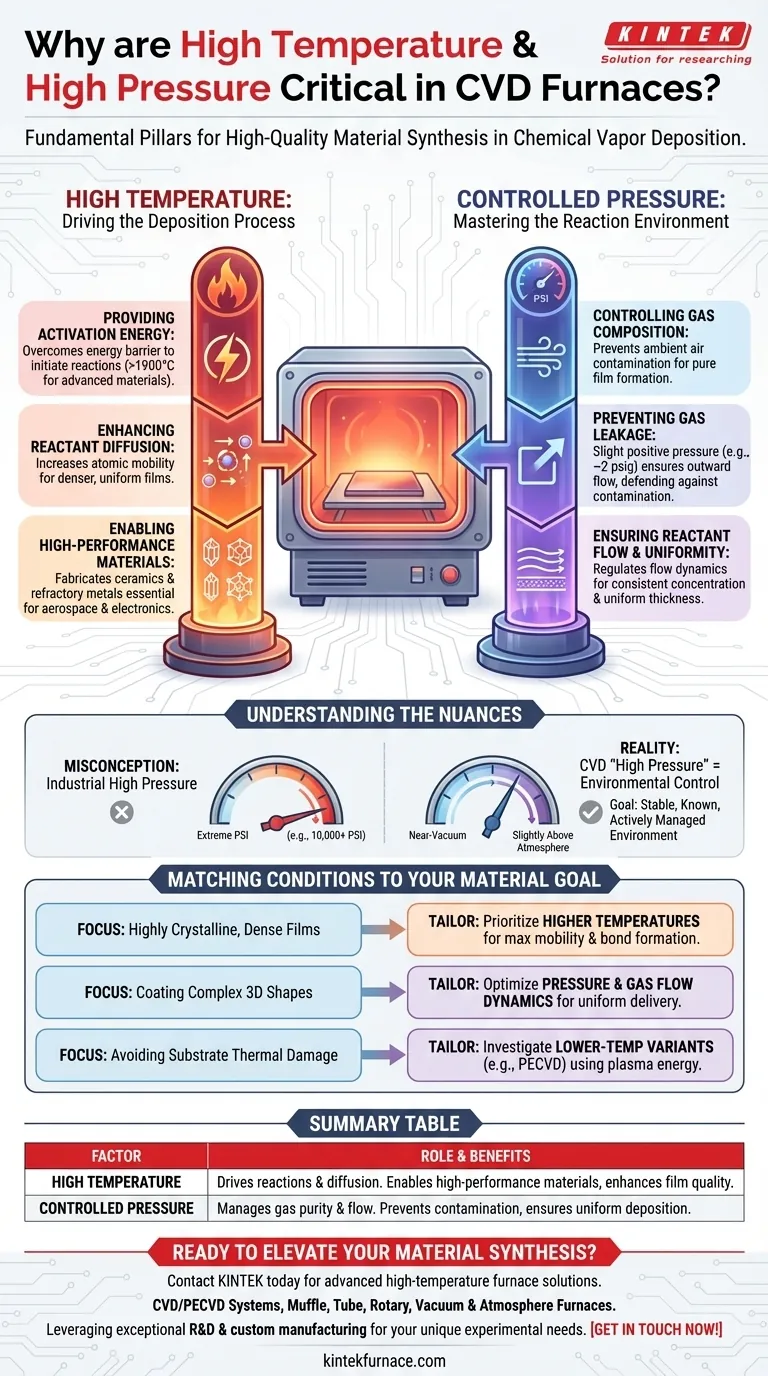

In Chemical Vapor Deposition (CVD), high temperature and a controlled pressure environment are the two fundamental pillars that enable the synthesis of high-quality materials. High temperature supplies the necessary energy to initiate and sustain chemical reactions on a substrate's surface, while a precisely managed pressure ensures the purity and stability of the gaseous environment, which is critical for forming a flawless film.

The power of a CVD furnace lies not just in reaching extreme conditions, but in its precise control over them. Temperature acts as the engine, driving the reaction rate and material formation. Pressure acts as the steering, guiding the gas-phase reactants to create a pure, high-quality film without contamination.

The Role of Temperature: Driving the Deposition Process

The temperature inside a CVD furnace is the primary lever for controlling the deposition process itself. Without sufficient thermal energy, the desired chemical reactions would not occur.

Providing Activation Energy

Most chemical reactions require an initial input of energy, known as activation energy, to begin. In a CVD furnace, high temperatures (often exceeding 1900°C for advanced materials) provide this energy, dramatically increasing the rate at which precursor gases react and form the solid film.

Enhancing Reactant Diffusion

Once reactant atoms land on the substrate surface, they must be able to move around to find their proper place in the material's crystal lattice. Heat increases this atomic mobility, a process called diffusion. Higher temperatures promote better diffusion, resulting in denser, more uniform, and higher-quality films.

Enabling High-Performance Materials

Many high-performance materials, such as certain ceramics or refractory metals, simply cannot be formed without extreme heat. The ability to operate at such high temperatures allows CVD to fabricate materials for demanding applications in aerospace, electronics, and research.

The Role of Pressure: Mastering the Reaction Environment

While temperature drives the reaction, pressure controls the environment in which that reaction happens. The goal is to create a perfectly managed atmosphere composed only of the desired reactant gases.

Controlling Gas Composition

The core principle of CVD is to build a material atom by atom from pure gas precursors. A controlled pressure environment is essential to prevent ambient air—primarily oxygen and nitrogen—from leaking into the chamber and causing unwanted reactions or contamination. This ensures the final film is pure.

Preventing Gas Leakage

By operating at a slight positive pressure (e.g., up to 2 psig), the furnace ensures that any potential leak flows outward, not inward. This simple principle is a powerful defense against contamination that could compromise the entire deposition process.

Ensuring Reactant Flow and Uniformity

A stable and controlled pressure helps regulate the flow dynamics of the precursor gases across the substrate. This ensures all parts of the substrate are exposed to a consistent concentration of reactants, which is critical for achieving a uniform film thickness.

Understanding the Nuances: "High Pressure" is Relative

It is crucial to understand that "high pressure" in the context of most CVD applications is a relative term. It does not imply the thousands of pounds per square inch (PSI) found in other industrial processes.

The Misconception of High Pressure

When discussing CVD, "high pressure" typically means any pressure above a hard vacuum. The actual operating range is often from a near-vacuum state up to a pressure slightly above the normal atmosphere.

The Goal is Control, Not Force

The primary objective is not to apply force, but to achieve absolute environmental control. Whether the process runs under vacuum or at a slight positive pressure, the key is that this pressure is stable, known, and actively managed to ensure the purity and consistency of the reaction.

Matching Conditions to Your Material Goal

The ideal balance of temperature and pressure is dictated entirely by the desired outcome. Understanding this interplay allows you to tailor the process to your specific goal.

- If your primary focus is creating highly crystalline, dense films: Prioritize higher temperatures to maximize atom mobility and ensure reactants have enough energy to form strong, ordered bonds.

- If your primary focus is coating complex, three-dimensional shapes: Concentrate on optimizing pressure and gas flow dynamics to ensure uniform reactant delivery to all surfaces.

- If your primary focus is avoiding thermal damage to the substrate: Investigate lower-temperature CVD variants (like Plasma-Enhanced CVD), where plasma energy, rather than heat, is used to drive the reaction.

Ultimately, mastering the interplay between temperature and pressure is the key to unlocking the full potential of CVD for fabricating advanced materials.

Summary Table:

| Factor | Role in CVD | Key Benefits |

|---|---|---|

| High Temperature | Drives chemical reactions and atomic diffusion | Enables high-performance materials, enhances film quality |

| Controlled Pressure | Manages gas purity and flow dynamics | Prevents contamination, ensures uniform deposition |

Ready to elevate your material synthesis with precision? Contact KINTEK today to explore our advanced high-temperature furnace solutions, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring pure, high-quality films for your lab. Get in touch now!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the main advantages of PECVD tube furnaces compared to CVD tube furnaces? Lower Temp, Faster Deposition, and More

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials