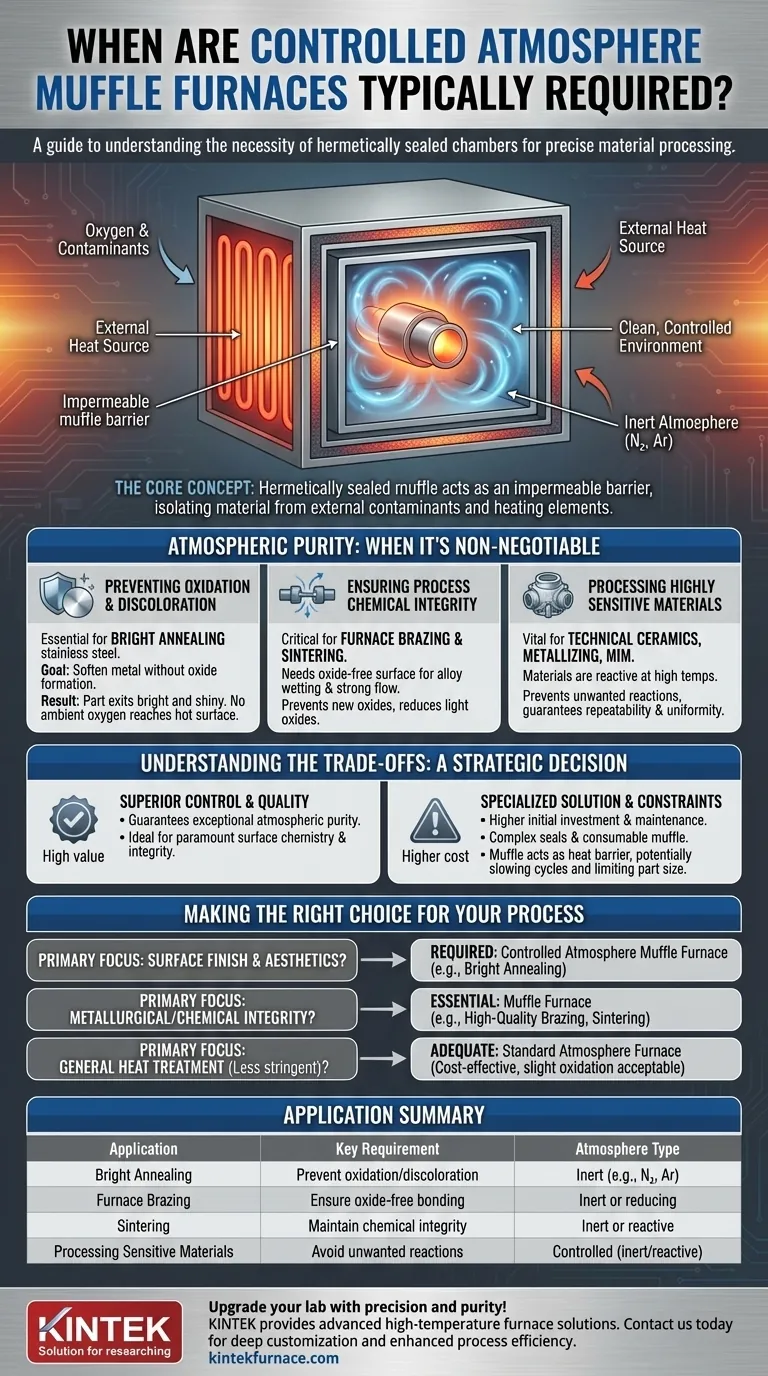

At its core, a Controlled Atmosphere Muffle Furnace is required when a manufacturing process demands absolute control over the atmospheric environment, completely isolating the material from external contaminants and even from the furnace's own heating elements. This is non-negotiable for the most demanding applications where surface oxidation, discoloration, or any unwanted chemical reaction would result in a failed part, such as in high-purity brazing or the bright annealing of stainless steel.

While many furnaces can control their internal atmosphere to a degree, a muffle furnace provides a hermetically sealed chamber—the muffle—that acts as an impermeable barrier. This guarantees the exceptional atmospheric purity necessary for processes where the final product's surface chemistry and integrity are paramount.

When is Atmospheric Purity Non-Negotiable?

The decision to use a muffle furnace is driven by the sensitivity of the material or process to its gaseous environment at high temperatures. In these cases, even trace amounts of oxygen or other impurities can be catastrophic.

Preventing Oxidation and Discoloration

For processes like the bright annealing of stainless steel, the goal is to soften the metal without creating any surface oxide layer. The part must exit the furnace as bright and shiny as it was when it entered.

A muffle creates a sealed environment filled with an inert gas like nitrogen or argon, ensuring that no ambient oxygen can reach the hot metal surface and cause discoloration or scaling.

Ensuring Process Chemical Integrity

Processes like furnace brazing and sintering rely on precise chemical interactions. In brazing, a clean, oxide-free surface is essential for the brazing alloy to wet and flow correctly, creating a strong joint.

The high-purity atmosphere inside a muffle prevents oxides from forming and can even help reduce existing light oxides, ensuring the integrity of the metallurgical bond.

Processing Highly Sensitive Materials

Advanced materials used in technical ceramics, metallizing, and Metal Injection Molding (MIM) are often highly reactive at processing temperatures.

Unwanted reactions with atmospheric impurities can fundamentally alter the material's final properties. A muffle furnace provides the inert or reactive atmosphere required, guaranteeing process repeatability and part uniformity.

Understanding the Trade-offs

While they offer superior control, muffle furnaces are a specialized solution. Understanding their limitations is key to making a sound technical and financial decision.

The Cost of Purity

Muffle furnaces are inherently more complex. The muffle itself is a consumable component made from high-grade metal alloys or ceramics, and the system requires robust seals. This results in a higher initial investment and ongoing maintenance cost compared to standard furnaces.

Throughput and Thermal Constraints

The muffle acts as an intermediary barrier for heat transfer, which can slightly slow down heating and cooling cycles compared to a direct-fired furnace. This can impact overall throughput in high-volume production. The physical size of the muffle also places a limit on the size of the parts that can be processed.

Is It Overkill for Your Process?

For many general-purpose heat treatments, such as tempering or stress-relieving non-critical parts, a standard furnace is perfectly adequate. If slight surface oxidation is acceptable or will be removed in a subsequent cleaning step, the expense of a muffle furnace is not justified.

Making the Right Choice for Your Process

Your specific process requirements and part quality standards will dictate whether a muffle furnace is a necessity or an over-specification.

- If your primary focus is surface finish and aesthetics: A controlled atmosphere muffle furnace is required for processes like bright annealing where any oxidation is a defect.

- If your primary focus is metallurgical or chemical integrity: A muffle furnace is essential for high-quality brazing, sintering, or processing reactive materials that demand a pure, uncontaminated atmosphere.

- If your primary focus is general heat treatment with less stringent surface requirements: A standard atmosphere furnace is likely more cost-effective if slight surface oxidation is acceptable or can be cleaned post-process.

Ultimately, choosing a muffle furnace is a strategic investment in guaranteed process purity and final part quality.

Summary Table:

| Application | Key Requirement | Atmosphere Type |

|---|---|---|

| Bright Annealing | Prevent oxidation and discoloration | Inert (e.g., nitrogen, argon) |

| Furnace Brazing | Ensure oxide-free surfaces for bonding | Inert or reducing |

| Sintering | Maintain chemical integrity | Inert or reactive |

| Processing Sensitive Materials | Avoid unwanted reactions | Controlled (inert/reactive) |

Upgrade your lab with precision and purity! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in materials science, metallurgy, or ceramics, our Controlled Atmosphere Muffle Furnaces ensure flawless results for processes like brazing and sintering. Contact us today to discuss how we can enhance your process efficiency and part quality!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process