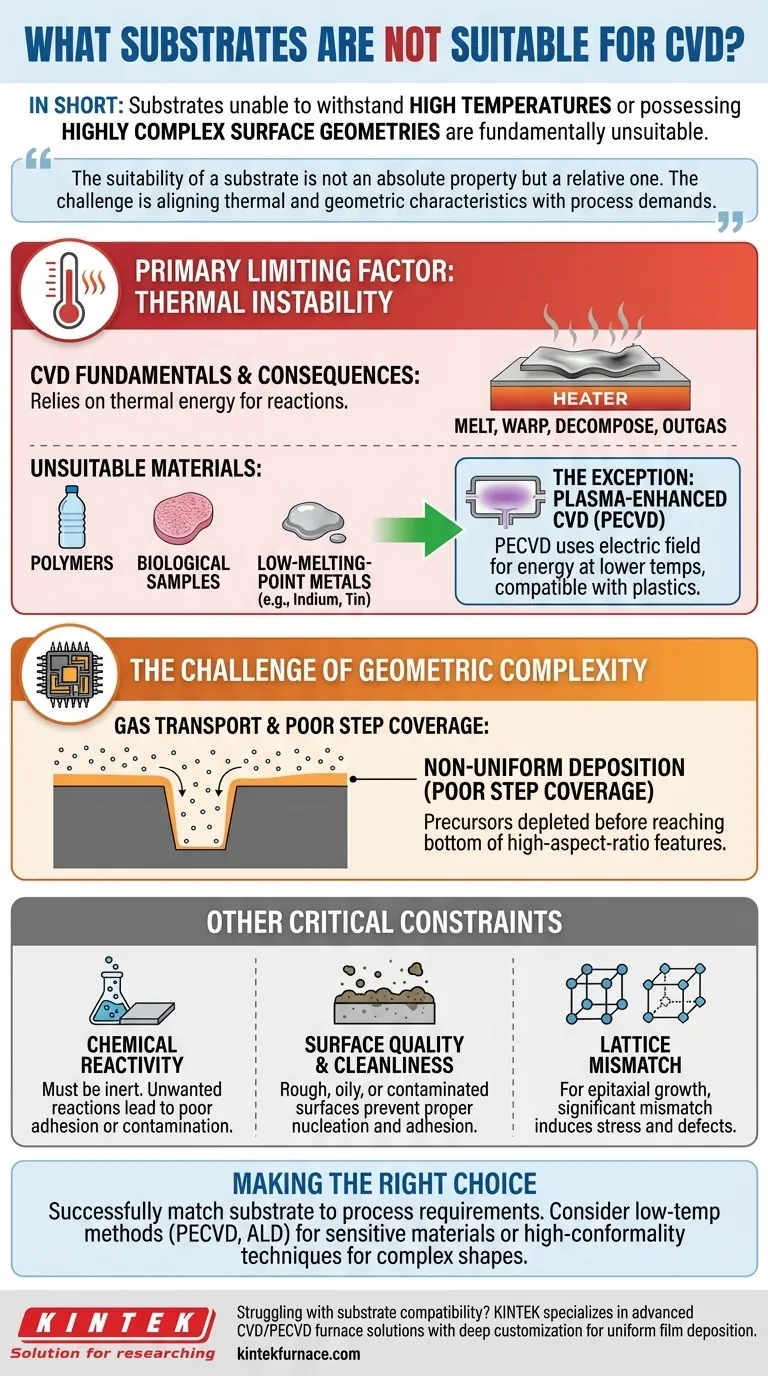

In short, substrates that cannot withstand high temperatures or that possess highly complex surface geometries are fundamentally unsuitable for many standard Chemical Vapor Deposition (CVD) processes. The primary failure points are thermal degradation of the substrate itself and the inability to form a uniform, consistent film over intricate features.

The suitability of a substrate is not an absolute property but a relative one. The central challenge is aligning the substrate's thermal and geometric characteristics with the specific temperature, chemical, and gas flow demands of the chosen CVD process.

The Primary Limiting Factor: Thermal Instability

Chemical Vapor Deposition fundamentally relies on thermal energy to drive the chemical reactions that form the desired film. This high-temperature requirement immediately disqualifies materials that cannot maintain their structural integrity under such conditions.

Understanding CVD's High-Temperature Environment

Most conventional CVD processes, such as thermal CVD, operate at temperatures ranging from a few hundred to over a thousand degrees Celsius. This heat is necessary to break down the precursor gases and enable them to react and deposit onto the substrate surface.

The Consequences of Thermal Sensitivity

When a substrate is heated beyond its stability point, it can melt, decompose, warp, or outgas. This not only destroys the substrate but also contaminates the reaction chamber and prevents the formation of a usable film.

Materials like most polymers, biological samples, or low-melting-point metals (e.g., indium, tin) are classic examples of thermally unsuitable substrates for standard CVD.

The Exception: Lower-Temperature CVD Variants

It is critical to note that variants like Plasma-Enhanced CVD (PECVD) were developed specifically to address this limitation. PECVD uses an electric field to create a plasma, providing the energy for the reaction at much lower temperatures, often making it compatible with temperature-sensitive materials like plastics.

The Challenge of Geometric Complexity

The second major barrier is physical. CVD relies on precursor gases flowing over and diffusing to the substrate surface. Complex topographies can disrupt this process, leading to inconsistent and unreliable film deposition.

The Principle of Gas Transport

For a film to form, precursor molecules must travel from the gas phase to every part of the substrate's surface. This journey is influenced by gas pressure, flow dynamics, and the physical "line of sight" to the surface.

Why Complex Shapes Cause Problems

Substrates with high-aspect-ratio features, such as deep trenches or microscopic holes, pose a significant challenge. The precursor gases may be depleted before they can reach the bottom of these features, a problem known as poor step coverage or conformality.

The Result: Non-Uniform Deposition

This gas depletion leads to a film that is thick at the top opening of a feature but thin or non-existent at the bottom. This non-uniformity compromises the electrical, mechanical, or optical properties of the final device, rendering it ineffective.

Understanding the Trade-offs and Other Constraints

Beyond heat and geometry, other subtle but critical factors can make a substrate unsuitable for a specific CVD application.

Chemical Reactivity

The substrate must be chemically inert with respect to the precursor gases and the deposited film at the process temperature. Unwanted reactions can lead to poor film adhesion, the formation of an undesirable interface layer, or contamination of the film itself.

Surface Quality and Cleanliness

CVD is highly sensitive to the condition of the substrate surface. A surface that is rough, oily, or contaminated with particles will prevent proper nucleation and growth. This results in poor adhesion and a defective film structure.

Lattice Mismatch

In advanced applications like epitaxial growth, where a single-crystal film is grown, the substrate must have a similar crystal lattice structure to the film. A significant lattice mismatch induces stress and defects, disrupting the desired crystalline quality.

Making the Right Choice for Your Process

Selecting a substrate requires a clear understanding of your deposition method and final goal.

- If your substrate is temperature-sensitive: Explore low-temperature deposition techniques like Plasma-Enhanced CVD (PECVD) or Atomic Layer Deposition (ALD).

- If your substrate has complex geometry: Investigate methods known for high conformality, such as ALD, or carefully optimize CVD process parameters (pressure, temperature, flow rates) to improve step coverage.

- If your primary issue is film quality or adhesion: Scrutinize the substrate for potential chemical reactivity with your precursors and ensure its surface is impeccably cleaned and prepared before deposition.

Ultimately, successful deposition is achieved by thoughtfully matching the substrate to the precise requirements of the process.

Summary Table:

| Limiting Factor | Description | Examples of Unsuitable Substrates |

|---|---|---|

| Thermal Instability | Substrates that degrade at high CVD temperatures (e.g., melting, warping) | Polymers, biological samples, low-melting-point metals (e.g., indium, tin) |

| Geometric Complexity | Substrates with intricate features that hinder uniform gas flow and film deposition | High-aspect-ratio structures like deep trenches and microscopic holes |

| Other Constraints | Issues like chemical reactivity, poor surface quality, or lattice mismatch | Rough, contaminated surfaces; chemically reactive materials; mismatched crystals for epitaxy |

Struggling with substrate compatibility in your CVD processes? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems, tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to overcome thermal and geometric challenges, ensuring uniform film deposition and enhanced experimental outcomes. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems can optimize your lab's efficiency and success!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What environments does a PECVD system provide for silicon nanowires? Optimize Growth with Precise Thermal Control

- How does a PECVD system contribute to (n)poly-Si layers? High-Throughput In-Situ Doping Explained

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- Why is a high-precision PECVD system required in ACSM? Enable Low-Temperature Atomic-Scale Manufacturing