A vacuum furnace supports nearly all major heat treatment processes. This includes common applications like hardening (quenching), tempering, annealing, and brazing, as well as more specialized tasks such as sintering, carburizing, nitriding, and stress relieving. The core advantage is the controlled, oxygen-free environment, which prevents surface reactions and ensures superior part quality.

The versatility of a vacuum furnace isn't just about the number of processes it can perform; it's about the exceptional control and purity it brings to each one. This makes it the ideal choice for processing sensitive, high-value materials where surface integrity and metallurgical consistency are non-negotiable.

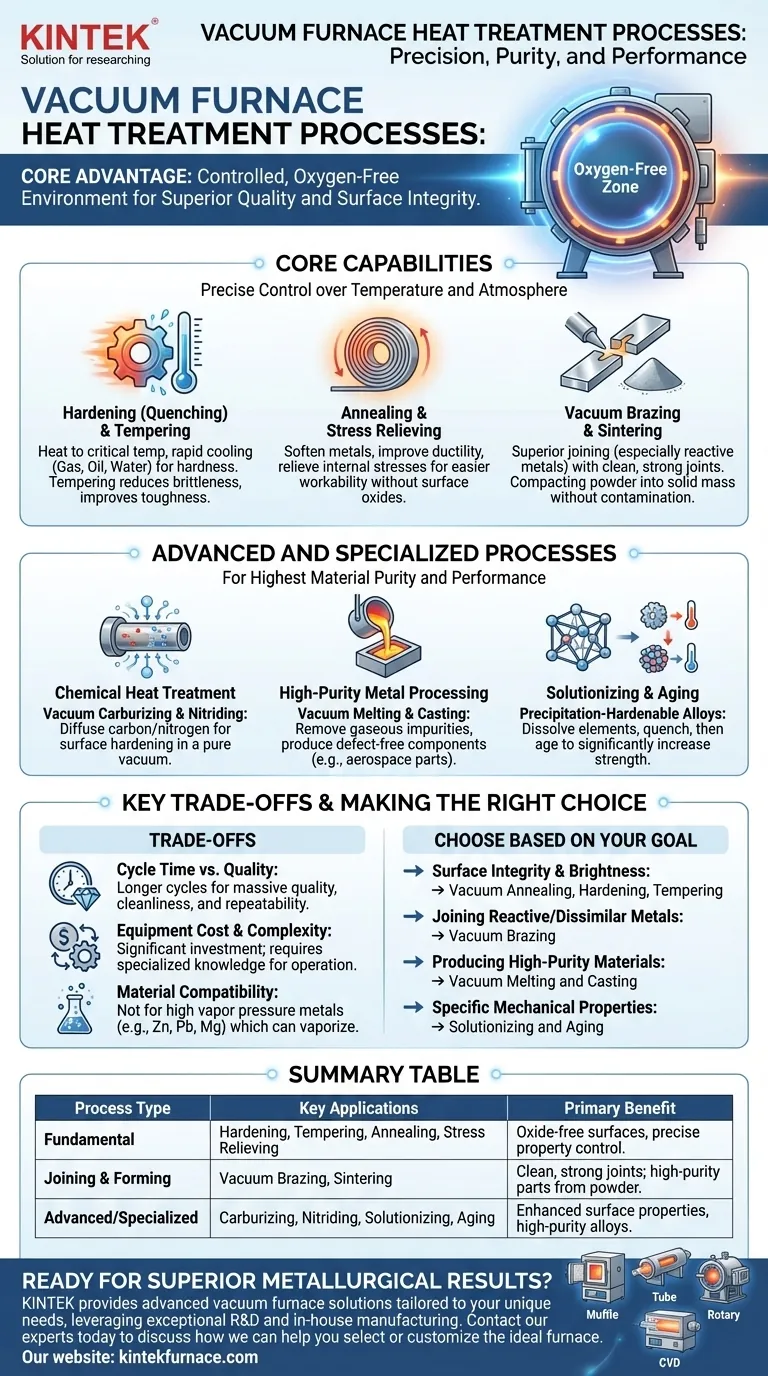

The Core Capabilities of Vacuum Heat Treatment

Vacuum furnaces achieve their flexibility by providing precise control over temperature and atmosphere. This allows for a wide range of metallurgical transformations while protecting the material from unwanted environmental effects.

Hardening and Tempering

Hardening, or quenching, involves heating a material to a critical temperature and then cooling it rapidly to achieve a specific hardness. Vacuum furnaces accommodate various quenching methods, including gas, oil, and water quenching.

Following hardening, tempering is used to reduce brittleness and improve toughness. The precise temperature control in a vacuum furnace is critical for achieving the exact mechanical properties required.

Annealing and Stress Relieving

Annealing is a process used to soften metals, improve ductility, and relieve internal stresses, making them easier to work with.

Stress relieving is a similar, lower-temperature process that reduces internal stresses caused by manufacturing processes like welding or machining without significantly changing the material's properties. In both cases, the vacuum ensures a bright, oxide-free surface finish.

Brazing and Sintering

Vacuum brazing is a superior method for joining metals, especially reactive materials like titanium. The oxygen-free environment prevents the formation of oxides, resulting in exceptionally clean and strong joints.

Sintering is the process of compacting and forming a solid mass of material from powder by applying heat. A vacuum environment is crucial for preventing contamination and ensuring the purity of the final sintered part.

Advanced and Specialized Vacuum Processes

Beyond the fundamentals, vacuum furnaces are essential for advanced applications that demand the highest level of material purity and performance.

Chemical Heat Treatment

While seemingly counterintuitive, a vacuum can be used for chemical treatments. Processes like vacuum carburizing and nitriding involve first creating a pure vacuum and then introducing a precise amount of a specific process gas to diffuse carbon or nitrogen into the material's surface, hardening it.

High-Purity Metal Processing

Induction-heated vacuum furnaces are central to creating high-purity metals and alloys. This includes vacuum melting to remove gaseous impurities and vacuum casting to produce components, such as aerospace turbine blades, that are free from porosity and defects.

Solutionizing and Aging

These processes are used for precipitation-hardenable alloys. Solutionizing involves heating the material to dissolve alloying elements, followed by quenching. Aging is a subsequent, lower-temperature treatment that allows these elements to precipitate, significantly increasing the material's strength.

Understanding the Key Trade-offs

While incredibly versatile, choosing a vacuum furnace involves understanding its specific operational characteristics and limitations.

Cycle Time vs. Quality

Vacuum furnace cycles can be longer than those in atmospheric furnaces due to the time required to pump down to the desired vacuum level. This trade-off of longer cycle time is made for a massive gain in quality, cleanliness, and process repeatability.

Equipment Cost and Complexity

Vacuum furnaces represent a significant capital investment. They are complex systems requiring specialized knowledge for operation and maintenance, including managing vacuum pumps, seals, and control systems.

Material Compatibility

Not all materials are suitable for vacuum processing. Metals with high vapor pressures, such as zinc, lead, or magnesium, can vaporize under a vacuum at high temperatures. This can damage the furnace and contaminate the workload.

Making the Right Choice for Your Application

Selecting the right process depends entirely on your end goal. The vacuum furnace offers a precise tool to achieve a range of outcomes.

- If your primary focus is surface integrity and brightness: Vacuum annealing, hardening, and tempering prevent oxidation, eliminating the need for post-process cleaning.

- If your primary focus is joining reactive or dissimilar metals: Vacuum brazing provides a contamination-free environment for creating superior, high-strength joints.

- If your primary focus is producing high-purity materials: Vacuum melting and casting are essential for removing impurities and creating flawless components for critical applications.

- If your primary focus is achieving specific mechanical properties in sensitive alloys: The precise control of a vacuum furnace is ideal for complex cycles like solutionizing and aging.

Ultimately, a vacuum furnace provides an unmatched level of control, enabling the creation of high-quality components that meet the most demanding specifications.

Summary Table:

| Process Type | Key Applications | Primary Benefit |

|---|---|---|

| Fundamental | Hardening, Tempering, Annealing, Stress Relieving | Oxide-free surfaces, precise property control |

| Joining & Forming | Vacuum Brazing, Sintering | Clean, strong joints; high-purity parts from powder |

| Advanced/Specialized | Carburizing, Nitriding, Solutionizing, Aging | Enhanced surface properties, high-purity alloys |

Ready to achieve superior metallurgical results with a high-temperature furnace solution tailored to your unique needs?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced vacuum furnace solutions. Our product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your experimental requirements—whether your focus is on surface integrity, joining reactive metals, or producing high-purity materials.

Contact our experts today to discuss how we can help you select or customize the ideal furnace for your specific heat treatment processes.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision