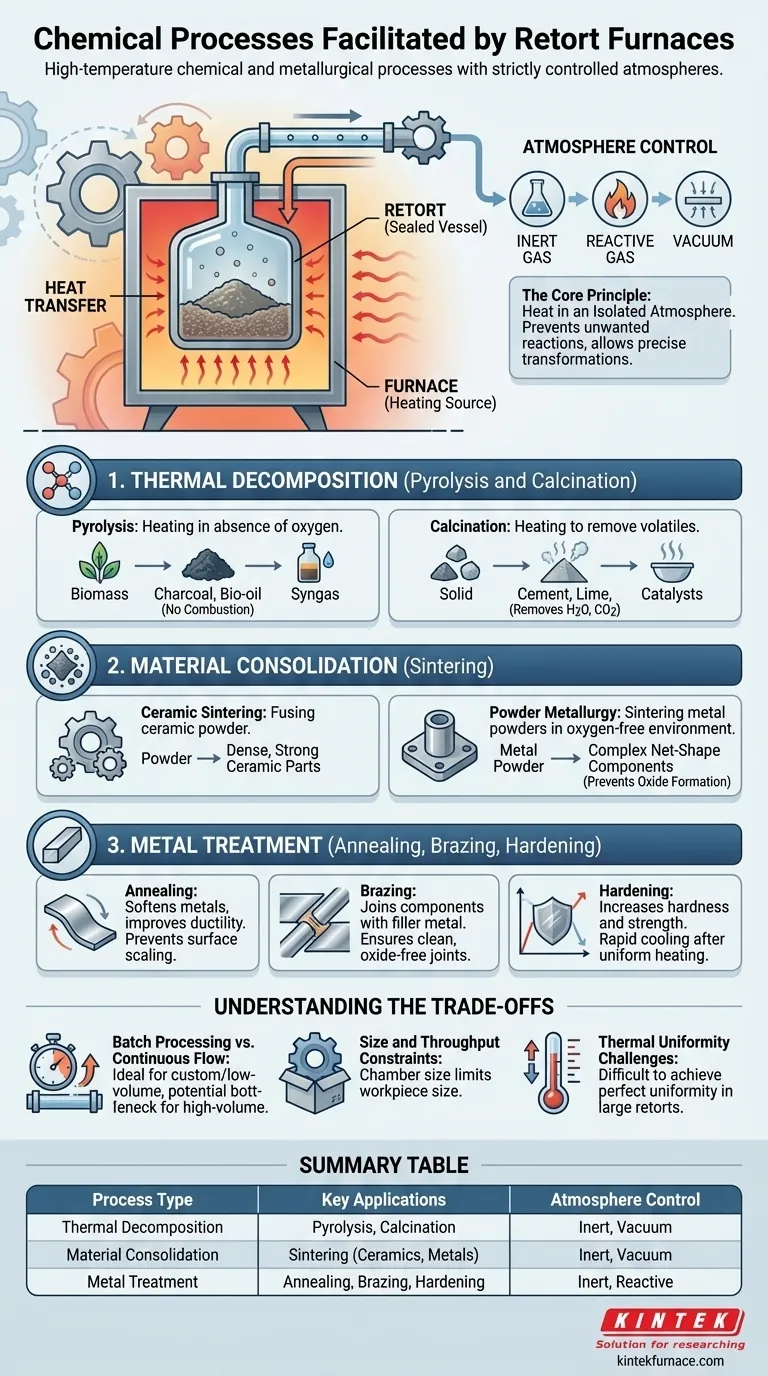

At their core, retort furnaces facilitate high-temperature chemical and metallurgical processes that require a strictly controlled atmosphere. They are used for a range of applications including the thermal decomposition of materials (pyrolysis and calcination), the consolidation of powders (sintering), and the heat treatment of metals (annealing, brazing, and hardening).

The defining feature of a retort furnace is not just its ability to generate heat, but its use of a sealed vessel (the retort) to isolate the workpiece from the external environment. This allows for precise control over the atmosphere—whether inert, reactive, or a vacuum—which is the key to preventing unwanted reactions and achieving specific material transformations.

The Core Principle: Heat in an Isolated Atmosphere

To understand the processes a retort furnace enables, you must first understand its fundamental design. Unlike a simple oven, its primary value comes from atmospheric control.

What is a "Retort"?

A retort is an airtight chamber or vessel placed inside a furnace. The material to be processed is put inside the retort, which is then sealed. The furnace heats the retort from the outside, and the heat transfers to the material within.

Why Atmospheric Control is Critical

This separation is crucial. By sealing the retort, you can purge the ambient air (which contains ~21% oxygen) and replace it with a specific gas or create a vacuum. This prevents oxidation at high temperatures, introduces gases that can participate in a reaction, or removes byproducts as they form.

Key Chemical and Metallurgical Processes

The ability to combine precise heat with a controlled atmosphere makes retort furnaces indispensable for several key industrial processes.

Thermal Decomposition (Pyrolysis and Calcination)

These processes use heat to break down compounds.

- Pyrolysis involves heating a material, such as biomass or shale, in the complete absence of oxygen. This prevents combustion and instead causes the material to decompose into valuable products like charcoal, bio-oil, and syngas.

- Calcination is the process of heating a solid to high temperatures to remove volatile substances, such as water or carbon dioxide. It is essential in producing cement, lime, and certain catalysts and pigments.

Material Consolidation (Sintering)

Sintering uses heat to fuse powder particles into a solid or porous mass without melting the material completely.

- Ceramic Sintering: This process gives ceramic parts their final strength and density.

- Powder Metallurgy: A retort furnace provides the oxygen-free environment needed to sinter metal powders into complex net-shape components, preventing the formation of strength-reducing oxides.

Metal Treatment (Annealing, Brazing, and Hardening)

For metals, controlling the atmosphere is paramount to preserving surface quality and metallurgical properties.

- Annealing: This heat treatment softens metals, making them more ductile and easier to work. An inert atmosphere prevents surface scaling and discoloration.

- Brazing: This process joins two metal components using a filler metal with a lower melting point. A controlled atmosphere (often nitrogen, hydrogen, or a vacuum) ensures a clean, strong, and oxide-free joint.

- Hardening: This process involves heating and then rapidly cooling a metal to increase its hardness and strength. The retort ensures uniform heating in a protective atmosphere before the quenching step.

Understanding the Trade-offs

While powerful, retort furnaces are not a universal solution. Understanding their limitations is key to using them effectively.

Batch Processing vs. Continuous Flow

Most retort furnaces are designed for batch processing. You load the retort, run the cycle, cool it down, and unload it. This is ideal for research, custom parts, or low-volume production but can be a bottleneck for high-volume, continuous manufacturing.

Size and Throughput Constraints

The physical size of the retort chamber inherently limits the size of the workpiece. While very large retort furnaces exist, they become increasingly complex and expensive, especially for maintaining atmospheric purity and thermal uniformity.

Thermal Uniformity Challenges

Achieving a perfectly uniform temperature throughout a large, sealed retort can be difficult. This requires careful furnace design, sensor placement, and control logic to prevent hot or cold spots that could lead to inconsistent product quality.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your desired outcome. A retort furnace is the superior choice when atmospheric integrity is non-negotiable.

- If your primary focus is creating materials in an oxygen-free environment: A retort furnace is essential for pyrolysis or developing carbon-based materials, as it prevents combustion.

- If your primary focus is improving metal properties or joining components: The controlled atmosphere of a retort is critical for annealing and brazing to prevent surface oxidation and ensure clean results.

- If your primary focus is consolidating powders into solid forms: A retort furnace provides the required high-temperature, oxygen-free environment for effective ceramic or metallurgical sintering.

- If your primary focus is removing volatile compounds from a material: The retort's ability to manage temperature and atmosphere during calcination is key to driving off specific substances without unwanted side reactions.

Ultimately, a retort furnace is the definitive tool when precise atmospheric control is just as critical to the process as the application of heat.

Summary Table:

| Process Type | Key Applications | Atmosphere Control |

|---|---|---|

| Thermal Decomposition | Pyrolysis, Calcination | Inert, Vacuum |

| Material Consolidation | Sintering (Ceramics, Metals) | Inert, Vacuum |

| Metal Treatment | Annealing, Brazing, Hardening | Inert, Reactive |

Elevate your laboratory processes with KINTEK's advanced retort furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, such as pyrolysis, sintering, or metal treatments. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing