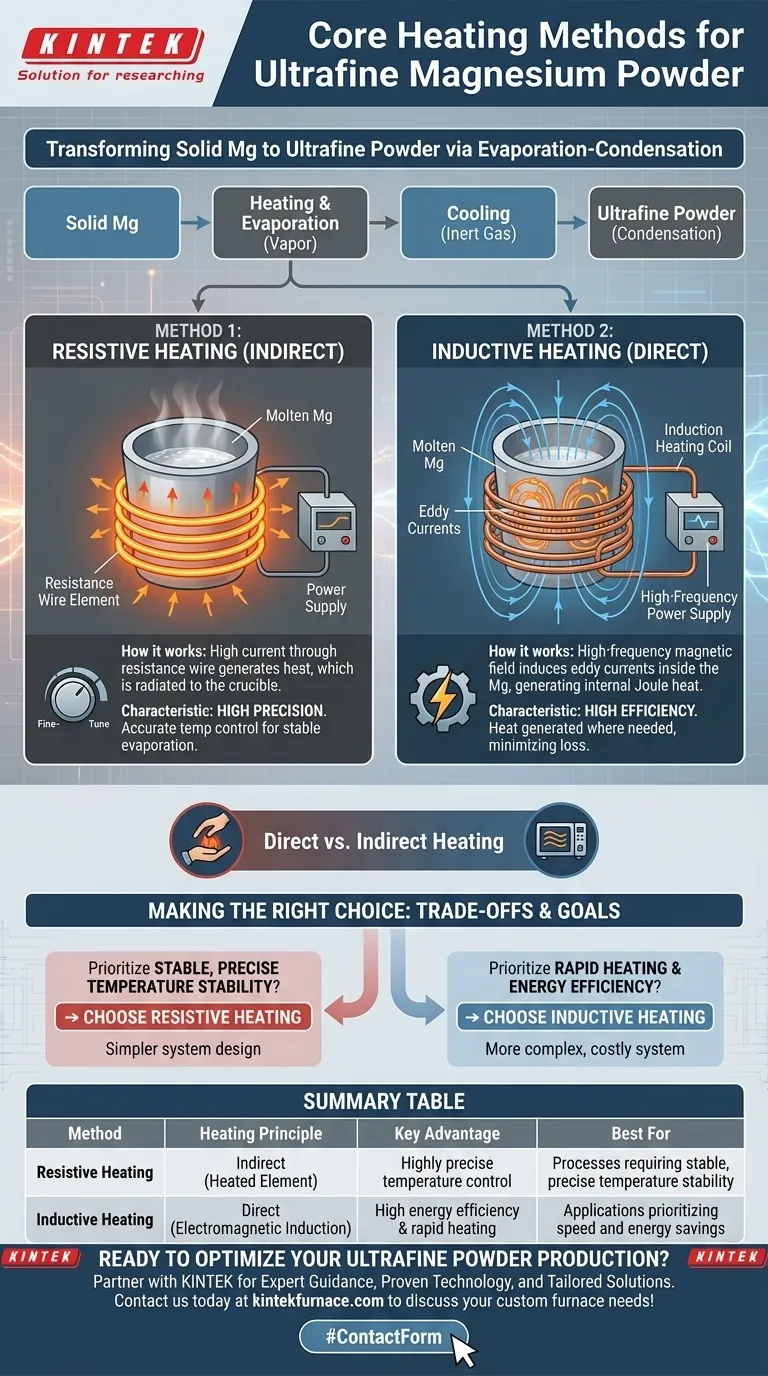

In the production of ultrafine magnesium powder, the two principal methods used to heat and vaporize the magnesium are resistive heating evaporation and inductive heating evaporation. Each method leverages a distinct physical principle to generate the intense heat required for the evaporation-condensation process.

The core difference lies in how heat is generated and transferred: resistive heating relies on an external, heated element, while inductive heating generates heat directly within the magnesium itself through electromagnetic fields.

The Role of Heating in Powder Synthesis

The fundamental goal of these heating methods is to transform solid magnesium into a vapor. This is the first step in the evaporation-condensation process.

The Evaporation-Condensation Cycle

Once the magnesium reaches a high enough temperature, it evaporates into a gas. This hot magnesium vapor is then introduced into a cooler, inert gas atmosphere.

The rapid cooling causes the vapor to condense directly into extremely small, or "ultrafine," solid particles, which are then collected as the final powder. Accurate heating is critical to controlling the rate of evaporation and, consequently, the final particle size and quality.

Method 1: Resistive Heating Evaporation

Resistive heating is an indirect method of heating that works on the principle of electrical resistance. It is analogous to the heating element in a toaster or an electric stove.

How It Works

A resistance wire or element is used as the primary heat source. When a high electrical current is passed through this wire, its natural resistance causes it to heat up significantly.

This heat is then transferred—typically through radiation and conduction—to a crucible containing the magnesium, raising its temperature to the point of evaporation.

The Defining Characteristic: Precision

The primary advantage of resistive heating is its potential for highly precise temperature control. The heat output is directly proportional to the electrical current, which can be regulated with extreme accuracy, allowing for a stable and consistent evaporation rate.

Method 2: Inductive Heating Evaporation

Inductive heating is a more direct and advanced heating method that uses electromagnetic induction to generate heat within the material itself.

How It Works

An induction heating coil generates a powerful, high-frequency alternating magnetic field. When the conductive molten magnesium is placed within this field, the field induces strong electrical currents, known as eddy currents, inside the magnesium.

The inherent electrical resistance of the magnesium causes these eddy currents to generate intense heat, a phenomenon known as Joule heating. The material effectively becomes its own heating element.

The Defining Characteristic: Efficiency

Control is achieved by adjusting the frequency and power of the induction coil. This method is often more energy-efficient because the heat is generated exactly where it is needed, minimizing thermal loss to the surrounding equipment.

Understanding the Trade-offs

Choosing between these two methods involves a trade-off between simplicity, control, and efficiency.

Direct vs. Indirect Heating

Resistive heating is indirect. The heat must travel from the wire to the crucible and then into the magnesium. This can lead to thermal lag and potential inefficiencies.

Inductive heating is direct. It heats the target material from the inside out, resulting in faster response times and potentially higher overall energy efficiency.

System Complexity

Resistive heating systems are often simpler in their fundamental design. The primary components are a power supply and a resistive element.

Induction heating systems, involving high-frequency power supplies and precisely engineered coils, can be more complex and costly to implement.

Making the Right Choice for Your Goal

Your selection depends on the specific priorities of your manufacturing or research process.

- If your primary focus is on stable, highly precise temperature stability: Resistive heating is often the preferred method due to its straightforward and finely tunable control mechanism.

- If your primary focus is on rapid heating rates and energy efficiency: Inductive heating is superior, as generating heat directly within the magnesium minimizes wasted energy and thermal lag.

Ultimately, both methods are proven pathways to producing high-quality ultrafine magnesium powder, with the choice depending on specific process requirements.

Summary Table:

| Method | Heating Principle | Key Advantage | Best For |

|---|---|---|---|

| Resistive Heating | Indirect heating via a heated element | Highly precise temperature control | Processes requiring stable, precise temperature stability |

| Inductive Heating | Direct heating via electromagnetic induction | High energy efficiency and rapid heating | Applications prioritizing speed and energy savings |

Ready to Optimize Your Ultrafine Powder Production?

Choosing the right heating method is critical for achieving the desired particle size, quality, and efficiency in your lab or production line. KINTEK is here to help you make the best choice.

Why Partner with KINTEK?

- Expert Guidance: Our technical specialists will analyze your specific requirements for precision, throughput, and material properties to recommend the ideal heating solution.

- Proven Technology: Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique needs in high-temperature processing.

- Tailored Solutions: We provide furnaces and systems that can be configured for either resistive or inductive heating principles, ensuring you get the performance you need.

Contact us today using the form below to discuss how our high-temperature furnaces can enhance your ultrafine powder synthesis. Let's build the perfect solution for your research or manufacturing goals.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control