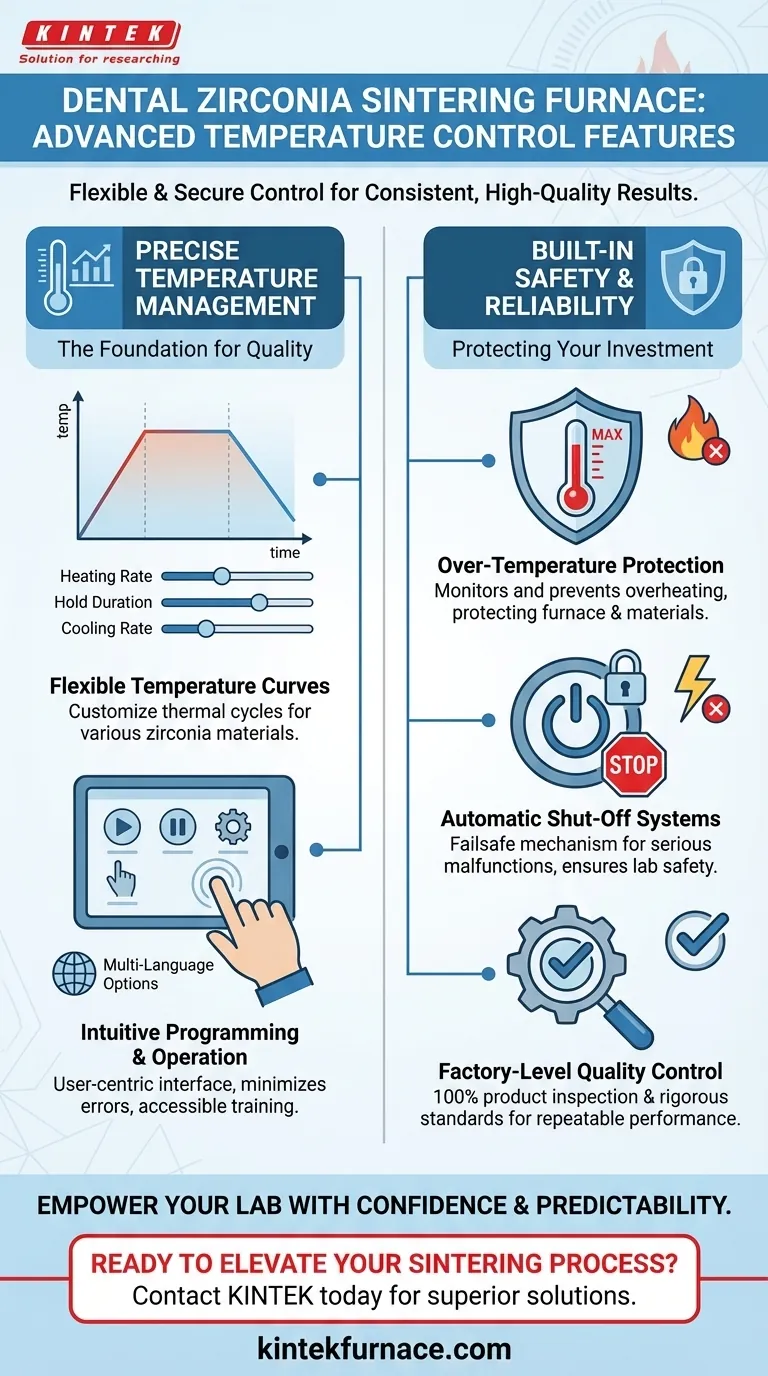

At its core, this dental zirconia sintering furnace provides highly flexible and secure temperature control designed for consistent, high-quality results. The system is built around user-programmable temperature curves, allowing full customization of the heating and cooling cycles to match the specific requirements of various zirconia materials, all managed through an intuitive interface and protected by integrated safety mechanisms.

The furnace's value is not just in reaching a target temperature, but in providing a programmable, repeatable, and safe thermal environment. This control is the foundation for achieving the desired strength, translucency, and fit for every dental restoration.

The Core of Sintering: Precise Temperature Management

The final physical and aesthetic properties of a zirconia restoration are directly determined by the sintering process. Minor deviations in temperature can compromise the outcome, making precise control an absolute necessity for any professional dental lab.

Flexible Temperature Curves

The furnace allows you to define the entire thermal cycle. This includes the rate of heating, the duration of the hold at peak temperature, and the rate of cooling.

This flexibility is critical because different types of zirconia (e.g., high-translucency vs. high-strength) from various manufacturers have unique, recommended sintering parameters. The ability to create and save custom programs ensures optimal results for every material you use.

Intuitive Programming and Operation

These complex temperature cycles are programmed through a touchscreen interface designed for simplicity and ease of use.

This user-centric design minimizes the need for extensive training and, more importantly, reduces the risk of human error when inputting critical sintering parameters. The inclusion of multiple language options further enhances accessibility and operational accuracy for diverse teams.

Built-In Safety and Reliability

Effective temperature control is as much about safety as it is about performance. Protecting your investment—both in the furnace and the zirconia restorations inside—is paramount. The system integrates several layers of protection to ensure safe, unattended operation.

Over-Temperature Protection

This is a primary safety mechanism. The system constantly monitors the internal temperature and will prevent it from exceeding the programmed maximum. This crucial feature protects the zirconia from being ruined by overheating and extends the life of the furnace's heating elements.

Automatic Shut-Off Systems

As a final failsafe, the furnace is equipped with an automatic shut-off feature. In the event of a serious malfunction or an unexpected temperature spike that bypasses other controls, the system will completely power down to prevent damage to the equipment and ensure the safety of your lab.

Factory-Level Quality Control

The reliability of these temperature systems is underpinned by rigorous manufacturing standards. With 100% product inspection and comprehensive quality control systems, the hardware is validated to perform as specified, ensuring that the temperature you set is the temperature you get, cycle after cycle.

Making the Right Choice for Your Lab

Understanding these features allows you to align the furnace's capabilities with your specific operational goals.

- If your primary focus is consistency across batches: The ability to save and recall precise, validated temperature curves is the key to achieving repeatable, high-quality outcomes.

- If your primary focus is using diverse materials: The flexibility to create unique programs for different zirconia brands and types is essential for a versatile and future-proof workflow.

- If your primary focus is operational safety: The combination of over-temperature protection and automatic shut-off provides the necessary security for running long sintering cycles, even overnight.

Ultimately, these integrated temperature control features empower your lab to produce superior dental restorations with confidence and predictability.

Summary Table:

| Feature | Description |

|---|---|

| Flexible Temperature Curves | Customizable heating/cooling rates and hold times for various zirconia types |

| Intuitive Programming | Touchscreen interface with multiple languages for easy operation |

| Over-Temperature Protection | Prevents overheating to safeguard materials and equipment |

| Automatic Shut-Off | Failsafe system for emergencies to ensure lab safety |

| Factory Quality Control | 100% inspection for reliable, repeatable temperature performance |

Ready to elevate your dental lab's sintering process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discover how our furnaces can deliver superior strength, translucency, and fit for your zirconia restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Spark Plasma Sintering SPS Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision