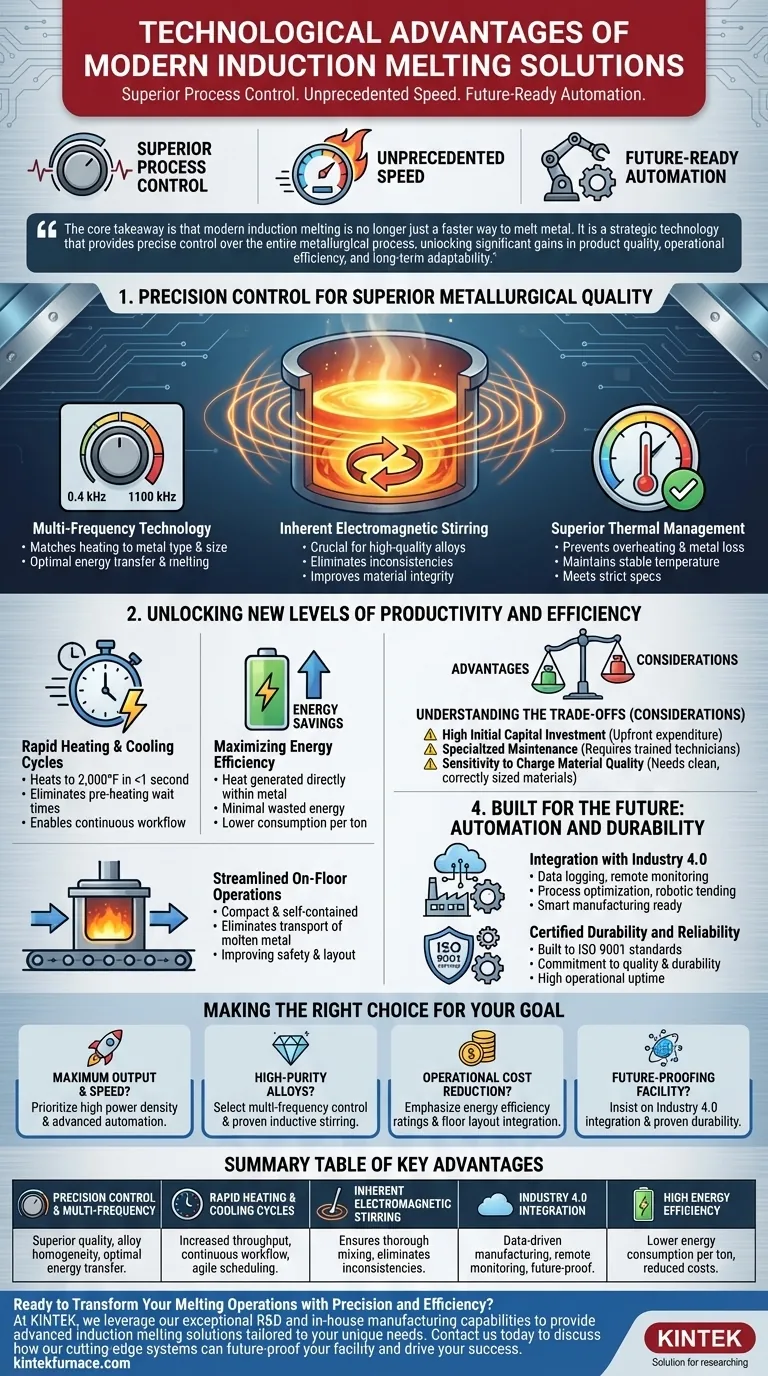

The key technological advantages of modern induction melting solutions are centered on superior process control, unprecedented speed, and future-ready automation. These systems move beyond simple heating, offering multi-frequency operation for material versatility, inherent electromagnetic stirring for higher alloy quality, and seamless integration with Industry 4.0 platforms for data-driven manufacturing.

The core takeaway is that modern induction melting is no longer just a faster way to melt metal. It is a strategic technology that provides precise control over the entire metallurgical process, unlocking significant gains in product quality, operational efficiency, and long-term adaptability.

Precision Control for Superior Metallurgical Quality

The primary advantage of modern induction systems is their ability to deliver precise, repeatable results. This control directly translates to higher-quality molten metal and finished products.

The Role of Multi-Frequency Technology

Modern furnaces offer a wide range of operating frequencies, from low frequencies around 0.4 kHz for large-volume melting to high frequencies up to 1100 kHz for small, specialized batches.

This flexibility allows you to perfectly match the heating characteristics to the specific metal type and charge size, ensuring optimal energy transfer and melting performance.

Inherent Stirring for Alloy Homogeneity

The electromagnetic field that heats the metal also creates a natural stirring action within the molten bath.

This inherent inductive stirring is crucial for producing high-quality alloys, as it ensures all elements are thoroughly mixed, eliminating inconsistencies and improving the final material's integrity.

Superior Thermal Management

Patented designs in modern systems, such as advanced electromagnetic die-casting furnaces, provide exceptional thermal management.

This prevents overheating, reduces metal loss due to oxidation, and maintains a stable temperature, all of which are critical for meeting strict metallurgical specifications.

Unlocking New Levels of Productivity and Efficiency

Beyond quality, modern induction technology is engineered to maximize throughput and minimize waste, directly impacting your bottom line.

Rapid Heating and Cooling Cycles

Induction can heat metal to over 2,000°F in less than a second. This incredible speed eliminates the long pre-heating and wait times associated with traditional fuel-fired furnaces.

Because the system also cools rapidly, it enables a continuous workflow, removing bottlenecks and allowing for more agile production scheduling.

Maximizing Energy Efficiency

Induction heating is a highly efficient process because the heat is generated directly within the metal itself. There is minimal wasted energy heating the surrounding chamber or atmosphere.

This direct heating method results in significantly lower energy consumption per ton of metal melted compared to older technologies.

Streamlined On-Floor Operations

The compact and self-contained nature of modern induction furnaces allows them to be placed directly on the production floor.

This eliminates the need to transport molten metal across a facility, improving safety, reducing heat loss, and creating a more efficient operational layout.

Understanding the Trade-offs

While the advantages are significant, a responsible evaluation requires acknowledging the associated considerations. These are not weaknesses but rather factors to be managed.

High Initial Capital Investment

State-of-the-art induction systems with advanced automation and multi-frequency capabilities represent a substantial upfront capital expenditure compared to more basic melting equipment.

The Need for Specialized Maintenance

The sophisticated power electronics and control systems in modern furnaces require technicians with specialized training for maintenance and troubleshooting, which can be a different skill set than that required for traditional furnaces.

Sensitivity to Charge Material Quality

Induction melting performs optimally with clean, correctly sized, and chemically known charge materials. Excessive dirt, oil, or moisture on scrap can impact efficiency and safety.

Built for the Future: Automation and Durability

Modern solutions are not just designed for today's needs but are built as platforms for future growth and reliability.

Integration with Industry 4.0

These systems are "future-ready" with automation capabilities that allow for seamless integration with plant-wide control systems.

This enables data logging, remote monitoring, process optimization, and robotic tending, aligning your foundry or facility with the principles of smart manufacturing.

Certified Durability and Reliability

Leading manufacturers build equipment to ISO 9001-certified production standards. This certification signals a commitment to quality control and durability, ensuring the furnace is a reliable, long-term asset with high operational uptime.

Making the Right Choice for Your Goal

The best induction solution depends entirely on your primary operational driver. Use your key objective to guide your evaluation.

- If your primary focus is maximum output and speed: Prioritize systems with high power density and advanced automation for rapid, continuous workflow.

- If your primary focus is high-purity alloys or specialty metals: Select a furnace with multi-frequency control and proven inductive stirring for superior metallurgical results.

- If your primary focus is operational cost reduction: Emphasize the system's energy efficiency ratings and its ability to integrate directly into your existing production floor layout.

- If your primary focus is future-proofing your facility: Insist on solutions with robust Industry 4.0 integration capabilities and a proven track record of durability.

Ultimately, investing in modern induction technology is a decision to adopt a more precise, efficient, and data-driven approach to melting.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Precision Control & Multi-Frequency | Superior metallurgical quality, alloy homogeneity, and optimal energy transfer for any metal type. |

| Rapid Heating & Cooling Cycles | Increased throughput, continuous workflow, and agile production scheduling. |

| Inherent Electromagnetic Stirring | Ensures thorough mixing of alloy elements, eliminating inconsistencies and improving material integrity. |

| Industry 4.0 Integration | Data-driven manufacturing, remote monitoring, process optimization, and future-proof automation. |

| High Energy Efficiency | Lower energy consumption per ton of metal melted, reducing operational costs. |

Ready to Transform Your Melting Operations with Precision and Efficiency?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced induction melting solutions tailored to your unique needs. Whether you're focused on producing high-purity alloys, maximizing throughput, or integrating with Industry 4.0, our expertise ensures you achieve superior metallurgical quality and operational efficiency.

Contact us today to discuss how our cutting-edge induction melting systems can future-proof your facility and drive your success.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications