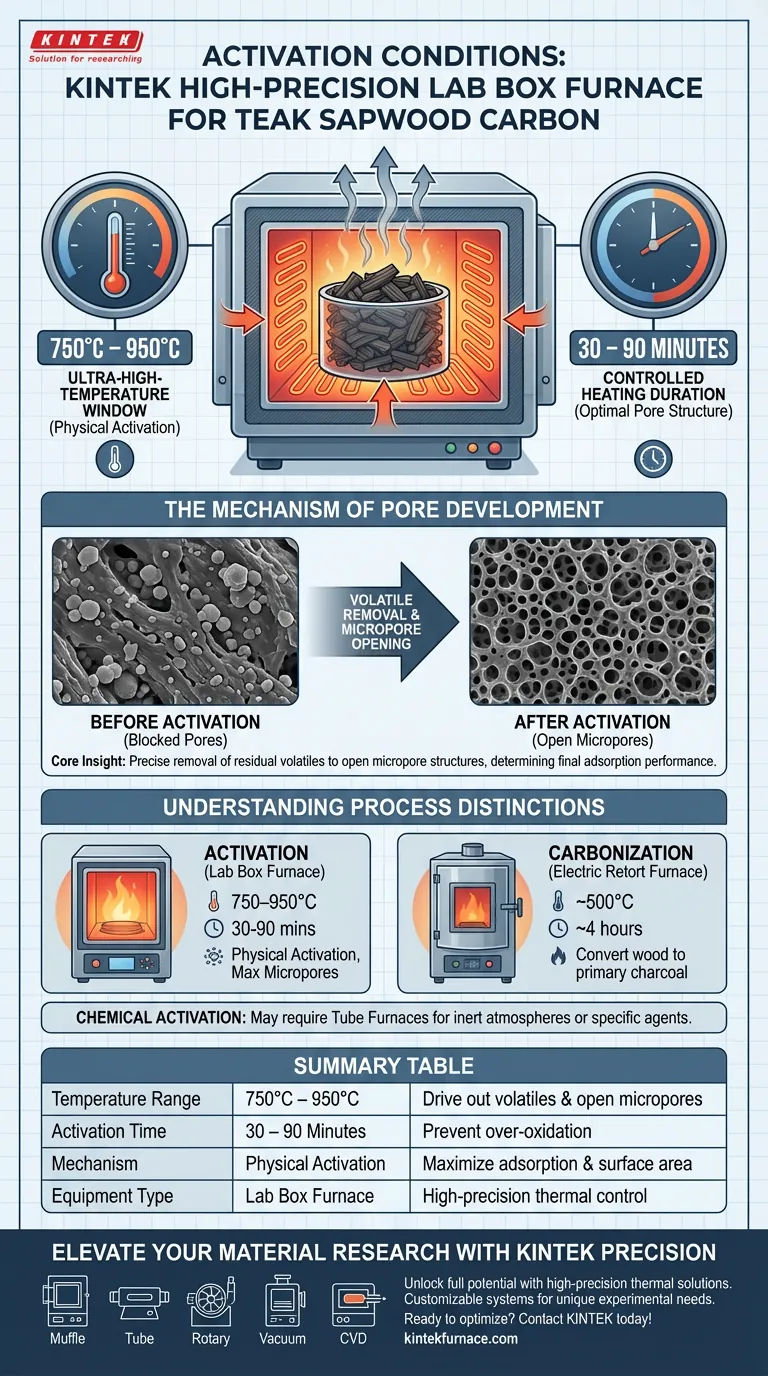

A high-precision laboratory box furnace establishes specific activation conditions characterized by an ultra-high-temperature environment ranging from 750°C to 950°C. These conditions are maintained for a precise duration of 30 to 90 minutes to facilitate the physical activation of fast-growing teak sapwood.

Core Insight: The primary function of this thermal environment is not merely heating, but the precise removal of residual volatile matter to open micropore structures, which determines the final adsorption performance of the activated carbon.

Precise Thermal Parameters for Activation

The Ultra-High-Temperature Window

The laboratory box furnace is specifically engineered to operate within a 750°C to 950°C range.

This temperature band is critical for physical activation, distinct from lower-temperature processes used in earlier production stages.

Controlled Heating Duration

To achieve optimal pore structure, the furnace maintains these temperatures for a duration of 30 to 90 minutes.

This timeframe is strictly controlled to ensure sufficient activation without degrading the carbon matrix through over-oxidation.

The Mechanism of Pore Development

Eliminating Residual Volatiles

The high heat provided by the box furnace drives out any remaining volatile matter left over from the initial carbonization process.

By clearing these blockages, the furnace exposes the underlying carbon structure.

Opening Micropore Structures

The combination of temperature and time physically opens the micropore structures within the teak sapwood charcoal.

This structural expansion is the direct variable that dictates the adsorption capacity of the finished product.

Understanding the Process Distinctions

Activation vs. Carbonization

It is vital to distinguish this activation step from the initial carbonization (pyrolysis) phase.

Carbonization typically utilizes an electric retort furnace at lower temperatures (~500°C) for longer periods (e.g., 4 hours) to convert wood into primary charcoal. The box furnace is reserved for the subsequent high-heat activation.

Physical vs. Chemical Activation Requirements

While the box furnace excels at physical activation, chemical activation often requires different environmental controls.

For example, chemical activation using agents like zinc chloride or KOH may utilize tube furnaces or modified high-temperature furnaces to manage inert atmospheres (nitrogen flow) or specific heating rates to foster mesopore expansion.

Making the Right Choice for Your Goal

To maximize the quality of your teak sapwood activated carbon, align your equipment usage with the specific stage of production:

- If your primary focus is increasing surface area via physical activation: Utilize the box furnace to maintain 750°C–950°C for 30–90 minutes to maximize micropore development.

- If your primary focus is the initial conversion of raw wood: Do not use the box furnace; instead, employ an electric retort furnace at ~500°C to convert cellulose and lignin into charcoal.

- If your primary focus is chemical activation: Ensure your furnace setup can accommodate chemical agents and potential inert gas flows, rather than relying solely on the standard box furnace configuration.

Precision in thermal application is the single most important factor in defining the adsorption efficiency of your final carbon product.

Summary Table:

| Activation Parameter | Specification for Teak Sapwood | Goal of Condition |

|---|---|---|

| Temperature Range | 750°C – 950°C | Drive out volatiles & open micropores |

| Activation Time | 30 – 90 Minutes | Prevent over-oxidation of carbon matrix |

| Mechanism | Physical Activation | Maximize adsorption & surface area |

| Equipment Type | Lab Box Furnace | High-precision thermal control |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your activated carbon production with high-precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique experimental needs.

Whether you are refining micropore structures in biomass or developing advanced chemical activation processes, our equipment delivers the temperature stability and control accuracy your research demands.

Ready to optimize your activation parameters? Contact KINTEK today to find your perfect furnace solution!

Visual Guide

References

- Johanes Pramana Gentur SUTAPA, Robertus Danu PRIYAMBODO. Utilization of Sapwood Waste of Fast-Growing Teak in Activated Carbon Production and Its Adsorption Properties. DOI: 10.5658/wood.2024.52.2.118

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- Why is a high-temperature sintering furnace essential for HAp scaffolds? Master Hydroxyapatite Strength & Integrity

- What is a box type resistance furnace and how does it work? Discover Its Key Components and Benefits

- What is the primary attribute of a Muffle Furnace? Unlock Contaminant-Free Heating for Your Lab

- What is the function of a laboratory programmable furnace in biomass proximate analysis? Optimize Your Fuel Characterization

- How does a high-temperature muffle furnace ensure precision during phase transformation research of manganese ore?

- What are some specific applications of muffle furnaces? Unlock Precision in Heat Treatment and Analysis

- What core roles does a muffle furnace play in the crystal growth of NaNbO3:Pr3+? Enhance Your Material Synthesis