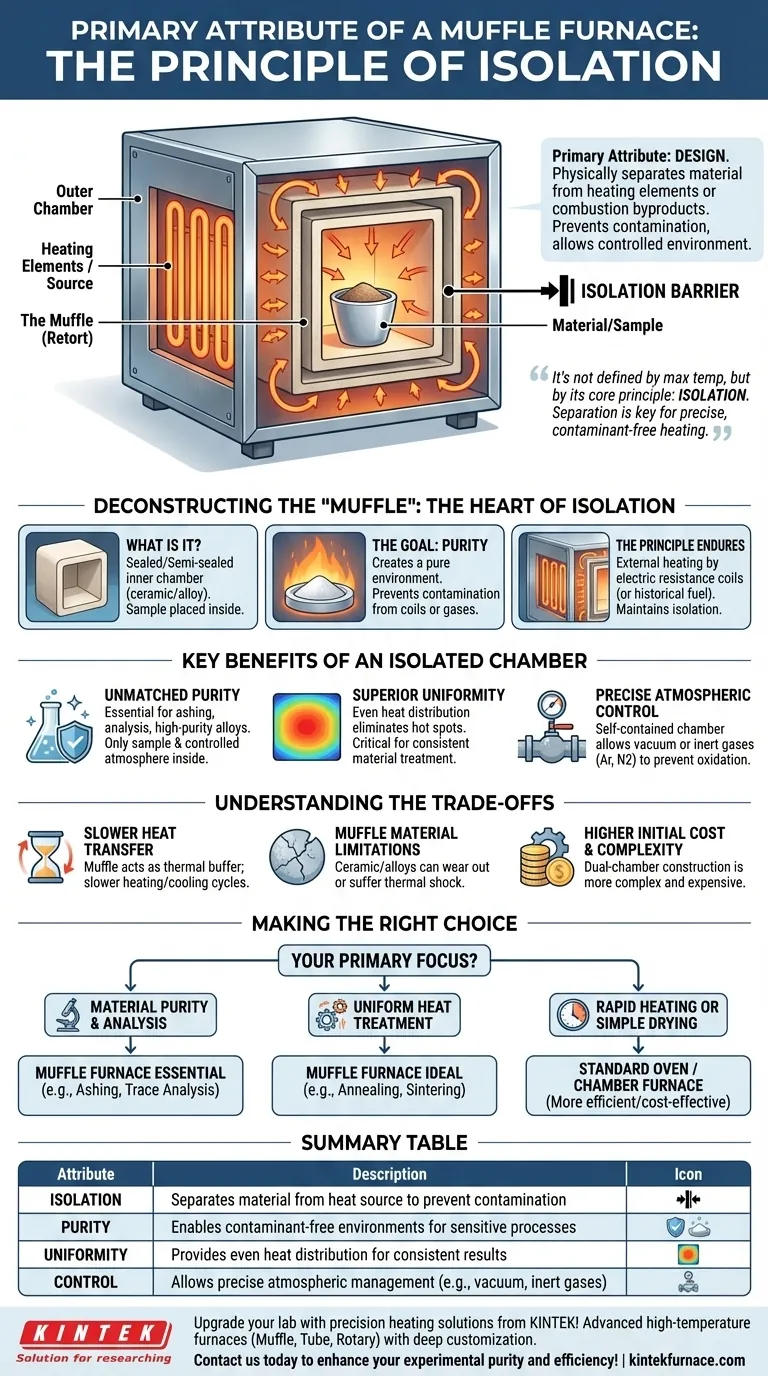

The primary attribute of a muffle furnace is its design, which physically separates the material being heated from the heating elements or combustion byproducts. This is achieved by placing the material inside an inner chamber, known as the "muffle" or "retort." This chamber is then heated from the outside, ensuring the material is never directly exposed to the heat source, thereby preventing contamination and allowing for a highly controlled environment.

A muffle furnace is not defined by its maximum temperature or its controls, but by its core principle: isolation. The separation of the workpiece from the heat source is the key feature that enables the precise, uniform, and contaminant-free heating required for sensitive applications.

Deconstructing the "Muffle": The Principle of Isolation

The name itself reveals the furnace's function. The material is "muffled," or shielded, from the raw energy source. This foundational concept has defined these instruments from their earliest forms to modern electric units.

What Is the Muffle?

The muffle is the heart of the furnace. It is a sealed or semi-sealed inner chamber typically made from high-temperature ceramic or a specialized metal alloy. Your workpiece or sample is placed inside this chamber for processing.

The Goal: Preventing Contamination

The primary purpose of this design is to create a pure heating environment. In historical fuel-fired furnaces, the muffle separated the material from combustion gases and soot. In modern electric furnaces, it separates the material from the heating coils, which can shed particles or react with the sample's atmosphere.

From Fuel to Electric: The Principle Endures

While most modern muffle furnaces are electric, the principle remains identical. Instead of being heated by flames, the muffle chamber is heated externally by high-temperature electric resistance coils. This design provides rapid, clean heating while maintaining the critical isolation of the workpiece.

The Key Benefits of an Isolated Chamber

This core design of isolation is not just a technical detail; it is the source of the furnace's most valued capabilities. It directly enables a level of precision that other heating methods cannot easily achieve.

Unmatched Purity for Sensitive Processes

For applications like ashing, chemical analysis, or creating high-purity alloys, any contamination can invalidate the results. The muffle ensures that the only things inside the chamber are the sample and any controlled atmosphere you introduce.

Superior Temperature Uniformity

By heating the entire exterior of the muffle chamber, the furnace creates exceptionally even heat distribution. This radiant and convective heat transfer inside the chamber eliminates hot spots, ensuring the entire workpiece experiences the same temperature, which is critical for consistent material treatment.

Precise Atmospheric Control

Because the muffle is a self-contained chamber, its atmosphere can be controlled. Air can be evacuated to create a vacuum, or the chamber can be purged with inert gases like argon or nitrogen to prevent oxidation during heat treatment.

Understanding the Trade-offs

No technology is without its limitations. Understanding the trade-offs of a muffle design is essential for making an informed decision.

Slower Heat Transfer

Because the heat must first saturate the muffle chamber before reaching the workpiece, heating and cooling cycles can be slower compared to furnaces with direct heating elements. The muffle acts as a thermal buffer.

Muffle Material Limitations

The muffle itself is a component that can wear out or fail. Ceramic muffles, while excellent for high temperatures and chemical resistance, can be susceptible to thermal shock if heated or cooled too quickly.

Higher Initial Cost and Complexity

The dual-chamber construction makes muffle furnaces inherently more complex and often more expensive than a simple chamber furnace or oven of a similar size. You are paying for the precision and purity that the design provides.

Making the Right Choice for Your Application

Ultimately, the decision to use a muffle furnace hinges on whether you need the benefits of its isolated chamber.

- If your primary focus is material purity and analysis: A muffle furnace is essential. Its ability to prevent contamination is non-negotiable for applications like ashing, burn-off, or trace metal analysis.

- If your primary focus is uniform heat treatment: The muffle furnace offers superior temperature homogeneity, making it ideal for processes like annealing, tempering, or sintering where consistent material properties are critical.

- If your primary focus is rapid heating or simple drying: A standard laboratory oven or a chamber furnace with exposed heating elements may be a more efficient and cost-effective choice, as the purity of a muffle design is not required.

Understanding that isolation is the core attribute empowers you to select the right tool based on the specific demands of your process.

Summary Table:

| Attribute | Description |

|---|---|

| Isolation | Separates material from heat source to prevent contamination |

| Purity | Enables contaminant-free environments for sensitive processes |

| Uniformity | Provides even heat distribution for consistent results |

| Control | Allows precise atmospheric management (e.g., vacuum, inert gases) |

Upgrade your lab with precision heating solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we offer advanced high-temperature furnaces like Muffle, Tube, and Rotary Furnaces, with deep customization to meet your unique needs. Contact us today to discuss how our products can enhance your experimental purity and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure