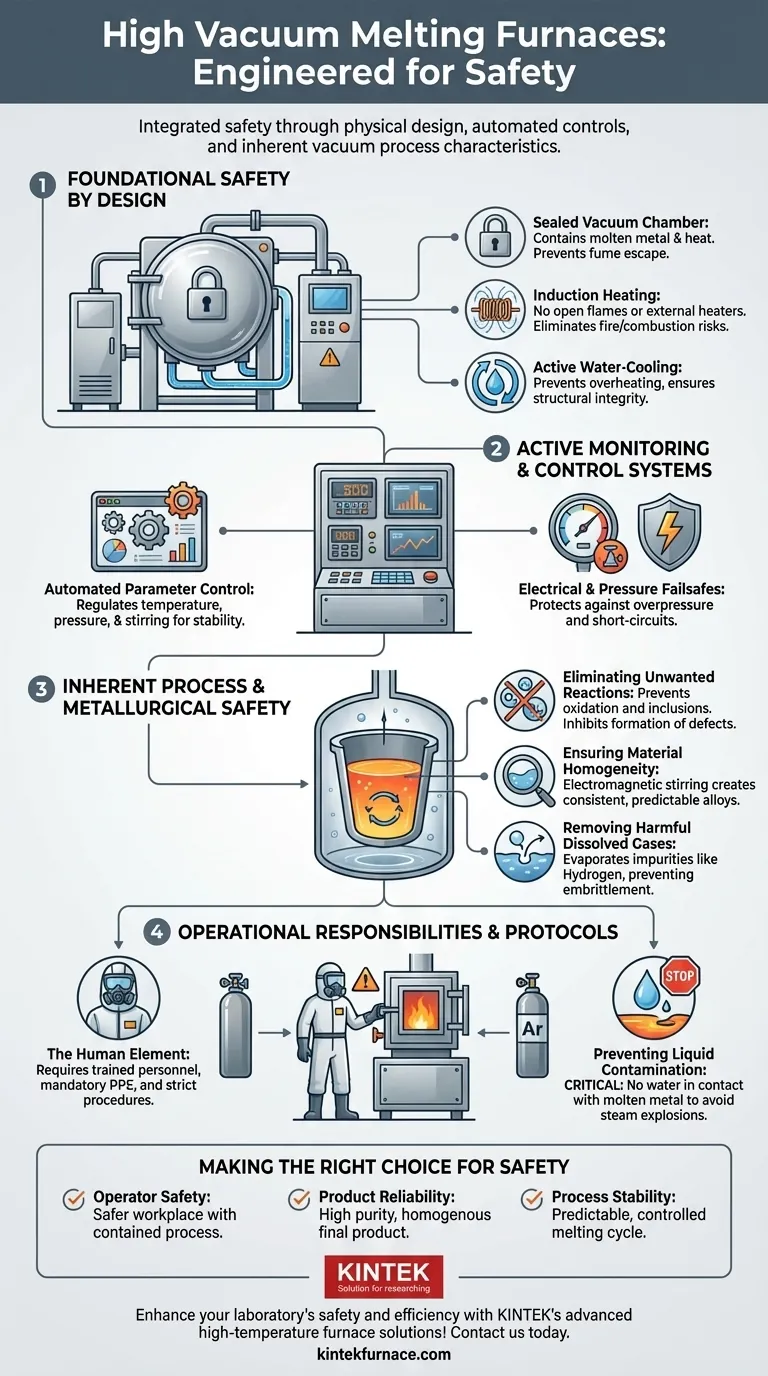

At their core, High Vacuum Melting Furnaces integrate safety through a combination of physical design, automated control systems, and the inherent nature of the vacuum process itself. Key built-in measures include robust water-cooling systems to prevent overheating, sealed vacuum chambers to contain the process, and electrical protections against overpressure and short-circuits. These features work in concert with automated controls that constantly monitor and regulate critical parameters.

The safety of a high vacuum furnace is not just a single feature, but a comprehensive strategy. It combines the elimination of traditional hazards like open flames with precise, automated control over the metallurgical process, resulting in a safer environment for operators and a more reliable final product.

Foundational Safety by Design

The fundamental architecture of a vacuum induction furnace is its first and most important line of defense, eliminating entire categories of risk found in traditional melting operations.

The Sealed Vacuum Chamber

The entire melting process occurs within a completely sealed chamber. This design immediately contains the high temperatures and molten metal, drastically reducing the risk of accidental burns or spills common with open-crucible methods.

Furthermore, this sealed environment prevents the escape of potentially harmful fumes or vaporized elements, protecting operators from respiratory hazards.

The Induction Heating Principle

Unlike fuel-fired furnaces, induction systems use electromagnetic fields to heat the metal directly. There are no open flames or external heating elements, which completely removes the risk of fire, combustion-related explosions, and exposure to toxic combustion byproducts.

Active Water-Cooling Systems

To manage the immense heat generated by the induction coil and the molten metal, these furnaces rely on extensive water-cooling systems. These systems circulate water through the chamber walls and power components, preventing overheating and ensuring the structural integrity of the furnace itself.

Active Monitoring and Control Systems

While the physical design provides passive safety, a layer of active, automated systems ensures the process remains within safe operating limits at all times.

Automated Parameter Control

Modern vacuum furnaces are governed by sophisticated control systems. These systems automatically monitor and regulate all critical parameters, including temperature, pressure, and electromagnetic stirring. This level of automation provides stability and repeatability, minimizing the potential for human error.

Electrical and Pressure Failsafes

The furnace is equipped with essential failsafes. Overpressure protection, typically via a relief valve, prevents a dangerous pressure buildup inside the chamber. Short-circuit protection and other electrical interlocks safeguard the high-power induction system from catastrophic failure.

Inherent Process and Metallurgical Safety

Some of the most significant safety benefits are a direct result of the vacuum melting process itself, leading to a higher quality and more predictable final product.

Eliminating Unwanted Reactions

Operating in a vacuum prevents the molten metal from reacting with oxygen and nitrogen from the air. This inhibits the formation of non-metallic oxide inclusions, which can create weak points in the final cast part.

The vacuum also helps remove harmful, volatile trace elements through controlled evaporation, resulting in a cleaner, purer, and more reliable alloy.

Ensuring Material Homogeneity

The use of electromagnetic stirring ensures the molten metal is completely homogenous. This prevents the segregation of different elements within the alloy, guaranteeing that the final product has a consistent and predictable mechanical strength without internal defects.

Removing Harmful Dissolved Gases

The vacuum environment is extremely effective at pulling dissolved gases, particularly hydrogen, out of the molten metal. The removal of hydrogen is critical for preventing hydrogen embrittlement, a phenomenon that can cause catastrophic failure in high-strength materials.

Operational Responsibilities and Protocols

While the technology is inherently safe, its operation still demands strict protocols and trained personnel to manage associated risks.

The Human Element

Proper safety depends on well-trained operators. This includes the mandatory use of personal protective equipment (PPE), adherence to all standard operating procedures, and ensuring unauthorized personnel are kept clear of the operational area.

Managing Process Gases

Vacuum furnaces often use inert gases like argon for backfilling the chamber. Safe handling, storage, and management of these high-pressure gas cylinders are critical components of the overall safety plan.

Preventing Liquid Contamination

A core safety rule is to prevent any liquids, especially water, from coming into contact with the molten metal. A leak into the furnace could cause a steam explosion. This underscores the importance of a well-maintained cooling system and disciplined operational practices.

Making the Right Choice for Your Goal

Understanding these safety dimensions allows you to align the technology's benefits with your primary objectives.

- If your primary focus is operator safety and environmental health: The furnace's sealed design, lack of open flames, and containment of fumes provide a fundamentally safer workplace compared to traditional methods.

- If your primary focus is final product reliability: The inherent process controls that remove impurities, eliminate gas porosity, and ensure alloy homogeneity are its greatest safety contribution.

- If your primary focus is process automation and stability: The integrated systems for monitoring temperature, pressure, and electrical loads ensure a predictable and highly controlled melting cycle.

Ultimately, a High Vacuum Melting Furnace delivers safety by transforming melting from an uncontrolled combustion process into a precisely managed and contained scientific procedure.

Summary Table:

| Safety Feature | Description |

|---|---|

| Sealed Vacuum Chamber | Contains high temperatures and molten metal, prevents fume escape |

| Induction Heating | No open flames, reduces fire and explosion risks |

| Water-Cooling Systems | Prevents overheating and maintains structural integrity |

| Automated Controls | Monitors and regulates temperature, pressure, and stirring |

| Electrical and Pressure Failsafes | Protects against overpressure and short-circuits |

| Inherent Process Safety | Eliminates unwanted reactions, removes gases, ensures homogeneity |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior performance and peace of mind. Contact us today to discuss how we can support your specific needs!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors