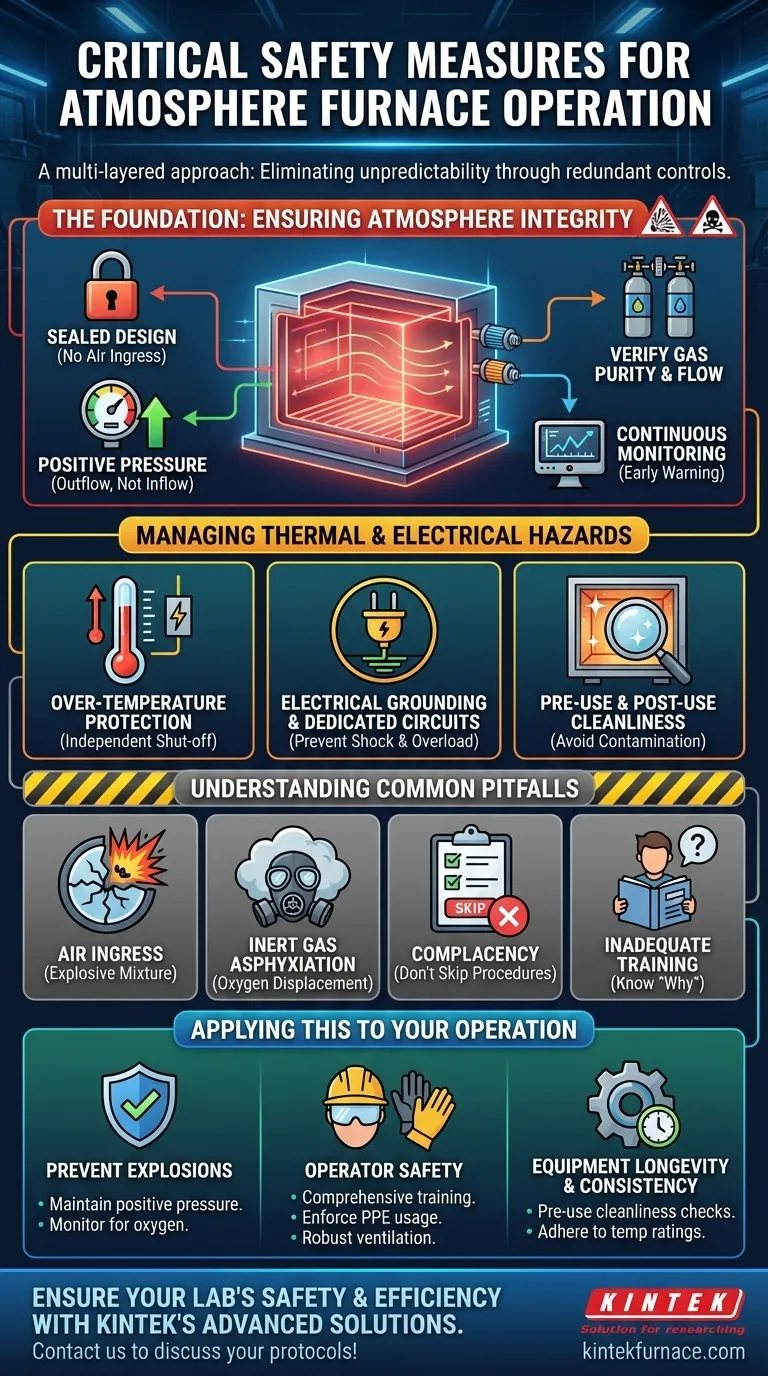

At its core, operating an atmosphere furnace safely requires a multi-layered approach that goes far beyond simple procedural checklists. The most critical measures involve maintaining absolute control over the furnace's internal environment through a sealed design and positive pressure, continuous monitoring of both temperature and gas composition, and enforcing strict operator protocols for everything from electrical safety to emergency response.

Safety in atmosphere furnace operation is not about a single action, but about building a system of redundant controls. The ultimate goal is to eliminate unpredictability by rigorously managing the three primary risk factors: the reactive atmosphere, the extreme heat, and the high-power electrical systems.

The Foundation: Ensuring Atmosphere Integrity

The special atmosphere is the most powerful and most hazardous element of the furnace. Its integrity is your top priority, as failure here can lead to explosions, ruined products, or asphyxiation.

Sealed Furnace Design

A tightly sealed furnace chamber is the first line of defense. Any breach in the seals can allow the controlled atmosphere to leak out or, more dangerously, allow external air to leak in.

Maintaining Positive Pressure

The furnace must always operate at a slight positive pressure relative to the outside environment. This ensures that if any microscopic leak exists, the internal gas will flow out rather than allowing oxygen-rich air to flow in, which is a primary cause of explosions when using flammable gases like hydrogen.

Verifying Gas Purity and Flow

The gas supply must be pure and delivered at the correct, stable flow rate. Impurities can compromise the metallurgical process, while incorrect flow can fail to purge air adequately or maintain positive pressure, creating a significant safety hazard.

Continuous Atmosphere Monitoring

Modern systems must include sensors for continuously monitoring the gas composition and pressure. These systems act as an essential early warning, alerting operators to any deviation from the set parameters long before it becomes a critical failure.

Managing Thermal and Electrical Hazards

Beyond the atmosphere itself, the inherent risks of high temperatures and high-voltage electricity demand their own dedicated safety measures.

Over-Temperature Protection

Every furnace must be equipped with an independent over-temperature protection circuit. This system shuts down the heating elements if the primary controller fails, preventing furnace damage, material destruction, and potential fires. Never exceed the furnace's rated temperature.

Electrical Grounding and Dedicated Circuits

Proper electrical grounding is non-negotiable to prevent the risk of electric shock. The furnace should be powered by a dedicated circuit with an appropriate breaker or gate to avoid overloading and creating a fire hazard.

Pre-Use and Post-Use Cleanliness

Operators must inspect the furnace chamber for cleanliness before every use. Residues from previous cycles can vaporize, contaminating the atmosphere and the product. Likewise, cleaning the furnace after use prevents buildup that could become a future hazard.

Understanding the Common Pitfalls

Trusting technology without understanding its failure modes is a critical mistake. The most severe accidents often happen when well-understood principles are ignored.

The Danger of Air Ingress

The single greatest risk when using flammable atmospheres (e.g., hydrogen) is the accidental introduction of air (oxygen). This creates an explosive mixture. Maintaining positive pressure and ensuring proper purging cycles are your most important defenses.

The "Invisible" Danger of Inert Gas

When using inert gases like nitrogen or argon, the primary risk shifts from explosion to asphyxiation. These gases displace oxygen. A leak in a poorly ventilated room can create a deadly, oxygen-deficient environment without any odor or visual cue.

Complacency with Procedures

Automated safety systems are a backstop, not a replacement for diligent operation. Skipping a pre-use cleanliness check, ignoring a minor pressure alarm, or becoming lax with PPE can defeat even the most advanced safety engineering.

Inadequate Operator Training

An operator who doesn't understand why a procedure exists is a liability. Training must cover not just the "how" but the "why" behind every safety measure, including a full understanding of emergency shutdown procedures.

How to Apply This to Your Operation

Use these principles to build a safety culture that protects your people, your product, and your equipment.

- If your primary focus is preventing explosions: Your non-negotiable priorities are maintaining positive pressure and continuously monitoring the furnace atmosphere for oxygen.

- If your primary focus is operator safety: Prioritize comprehensive training on emergency procedures, enforce proper PPE usage, and ensure robust ventilation for the workspace.

- If your primary focus is equipment longevity and process consistency: Stress the importance of pre-use cleanliness checks and strictly adhering to the furnace's maximum temperature ratings.

A rigorously implemented safety protocol transforms a potentially hazardous tool into a predictable and powerful manufacturing asset.

Summary Table:

| Safety Measure | Key Focus | Critical Actions |

|---|---|---|

| Atmosphere Integrity | Prevent explosions and asphyxiation | Sealed design, positive pressure, gas purity, continuous monitoring |

| Thermal and Electrical Management | Avoid overheating and electric shock | Over-temperature protection, electrical grounding, cleanliness checks |

| Operator Protocols | Enhance safety culture | Training, PPE usage, emergency procedures, ventilation |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements, helping you prevent hazards and achieve consistent results. Contact us today to discuss how we can support your safety protocols and enhance your operations!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results