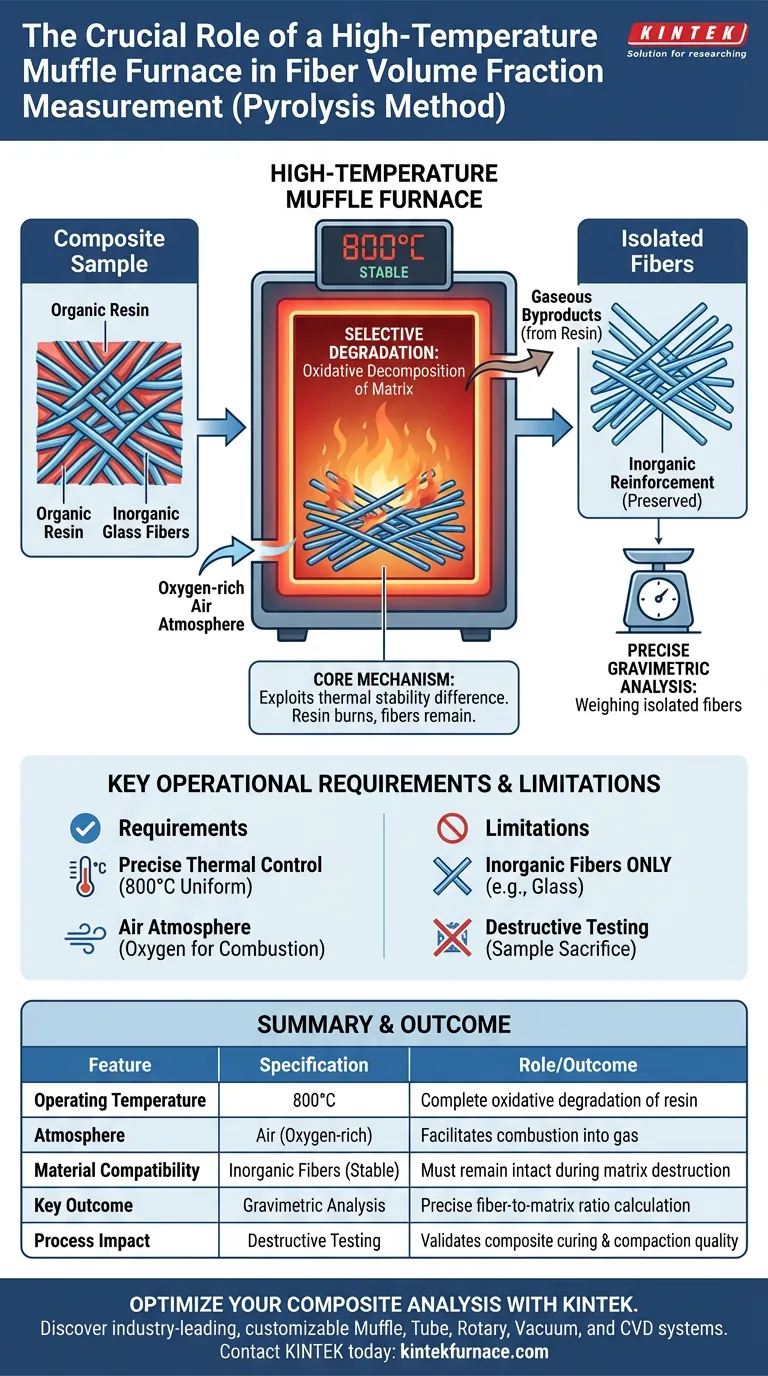

The high-temperature muffle furnace serves as the primary separation tool in determining fiber volume fraction via pyrolysis. It creates a stable, 800°C air environment that selectively removes the matrix material through complete oxidative degradation. By burning away the organic phenolic resin while preserving the inorganic glass fibers, the furnace enables the precise gravimetric analysis required to calculate the material's composition.

Core Takeaway The muffle furnace exploits the difference in thermal stability between organic resins and inorganic fibers. By ensuring the total combustion of the matrix without damaging the reinforcement, it provides the fundamental data needed to validate the quality of composite curing and compaction.

The Mechanism of Separation

Selective Degradation

The core function of the furnace is not simply heating, but selective destruction.

The composite consists of two distinct phases: an organic matrix (phenolic resin) and inorganic reinforcement (glass fibers).

The furnace creates an environment where the organic matrix cannot survive, causing it to decompose and oxidize completely.

Preservation of Reinforcement

Simultaneously, the furnace environment must be safe for the reinforcement material.

Inorganic glass fibers possess high thermal stability and remain intact at 800°C.

This selective process isolates the fibers, allowing them to be weighed without interference from the binder.

Operational Requirements

Precise Thermal Control

Accuracy depends on maintaining a specific, uniform temperature.

The primary reference specifies an operating temperature of 800°C.

Fluctuations below this point may result in incomplete resin burn-off, while excessive spikes could potentially alter the physical state of the glass.

Atmospheric Conditions

The process requires an air atmosphere within the chamber.

Oxygen is necessary to facilitate oxidative degradation, converting the solid resin into gaseous byproducts.

Without this airflow, the resin might char rather than burn away, leading to inaccurate weight measurements.

Evaluating Manufacturing Quality

Determining Fiber-to-Matrix Ratio

Once the resin is removed, the remaining mass represents the fiber content alone.

Comparing this final weight to the initial sample weight allows for a direct calculation of the fiber volume fraction.

Validating the Process

This measurement is a critical quality control metric.

It reveals the effectiveness of the curing and compaction process used during manufacturing.

Data derived from the furnace cycle helps engineers ensure the material meets the necessary strength and weight specifications.

Understanding the Trade-offs

Material Limitations

This method is strictly limited by the thermal properties of the constituents.

It is effective only because the glass fibers are inorganic and thermally stable in air at 800°C.

If the reinforcement fibers were organic (like aramid) or prone to oxidation (like carbon fiber) in an air atmosphere, the furnace would destroy the fibers along with the resin, rendering the test invalid.

Destructive Testing

The pyrolysis method is inherently destructive.

The sample used for analysis is physically altered and cannot be used for mechanical testing afterward.

This requires the sacrifice of representative material samples to gain insight into the batch quality.

Making the Right Choice for Your Goal

To obtain accurate fiber volume data, you must align your furnace parameters with the material limitations.

- If your primary focus is Measurement Accuracy: Ensure the furnace maintains a stable 800°C with sufficient airflow to guarantee the complete removal of organic impurities and resin.

- If your primary focus is Material Suitability: Verify that your reinforcement fibers are inorganic and capable of withstanding 800°C without degradation before selecting this method.

The high-temperature muffle furnace is the arbiter of truth for composite composition, provided the reinforcement material can survive the heat that destroys the matrix.

Summary Table:

| Feature | Specification/Requirement | Role in Pyrolysis |

|---|---|---|

| Operating Temperature | 800°C (Stable) | Ensures complete oxidative degradation of phenolic resins. |

| Atmosphere | Air (Oxygen-rich) | Facilitates combustion of organic matrix into gaseous byproducts. |

| Material Compatibility | Inorganic Fibers (e.g., Glass) | Must remain thermally stable while the matrix is destroyed. |

| Key Outcome | Gravimetric Analysis | Provides precise fiber-to-matrix ratios for quality validation. |

| Process Impact | Destructive Testing | Validates curing and compaction effectiveness in composites. |

Optimize Your Composite Analysis with KINTEK

Precision in pyrolysis begins with superior thermal control. KINTEK provides industry-leading muffle furnaces designed for the rigorous demands of material science and quality control. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific lab requirements.

Whether you are validating curing processes or determining fiber volume fractions, our high-temperature solutions deliver the stability and uniformity you need. Contact KINTEK today to discuss your unique heating needs with our specialists!

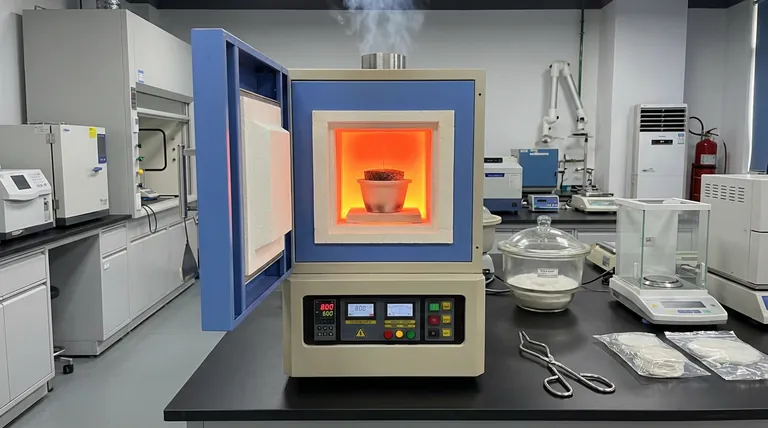

Visual Guide

References

- Xiaodong He, Hualian Li. A Study on the Compaction Behavior and Parameter Sensitivity of Curing Phenolic Thermal Protection Material Strips. DOI: 10.3390/polym17081045

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the temperature of a sintering oven? Master Material-Specific Thermal Cycles

- Why is atmosphere control important in a Muffle furnace? Unlock Precise Material Processing

- What factors should be considered when selecting a muffle furnace? Key Tips for Optimal Lab Performance

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- What role does a muffle furnace play in TiO2 sol-gel transformation? Achieve High-Performance Photocatalytic Coatings

- How does the digital interface of a muffle furnace enhance its functionality? Unlock Precision and Efficiency in Your Lab

- What makes muffle furnaces suitable for educational institutions? Safe, Cost-Effective Tools for Student Labs