In an educational setting, muffle furnaces are highly suitable because they offer a unique combination of professional-grade performance with the practical requirements of a teaching environment. They are specifically valued for their cost-effectiveness, user-friendly controls, inherent safety features, and compact designs that fit well within a typical laboratory space.

The true value of a muffle furnace in education is not just its ability to reach high temperatures. It is its capacity to provide a safe, controllable, and repeatable experimental environment, making it an ideal instrument for teaching core scientific principles without the complexities and hazards of industrial-scale equipment.

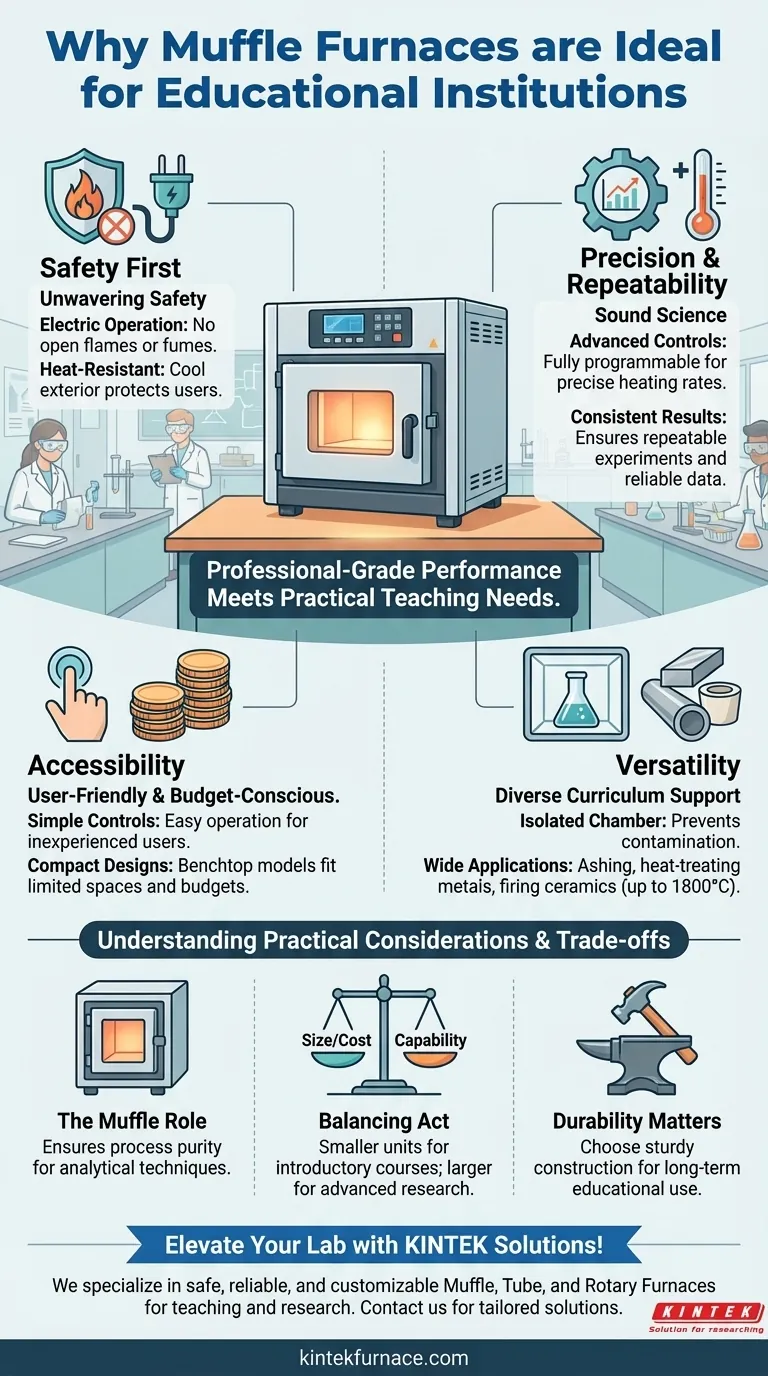

Why Muffle Furnaces Align with Educational Goals

The design and features of modern muffle furnaces directly address the core needs of educational institutions: safety, pedagogical effectiveness, and budget management. They serve as a bridge, allowing students to perform industry-relevant processes on a manageable and safe scale.

Unwavering Safety for Inexperienced Users

Nearly all modern muffle furnaces rely on clean and safe electric operation. This eliminates the open flames, fumes, and complex ventilation requirements associated with fuel-fired furnaces, which is a paramount concern in a student lab.

The furnace's construction includes heat-resistant materials and robust insulation, keeping the exterior relatively cool and protecting users from accidental burns.

Precision and Repeatability for Sound Science

A key feature is an advanced temperature control system. Many models are fully programmable, allowing instructors to set precise heating rates, target temperatures, and cooling profiles.

This ensures that experiments are highly repeatable across different student groups and lab sessions. The furnace's ability to create even heat distribution and maintain a homogeneous temperature throughout the chamber is critical for teaching students the importance of process control and obtaining consistent, reliable data.

Accessibility Through Simplicity and Budget

Muffle furnaces are designed with user-friendly controls, making them easy to operate even for students with no prior experience. This reduces training time and minimizes the risk of user error.

They are available in a range of sizes, including small benchtop models that are perfect for institutions with limited space or budgets. This accessibility makes high-temperature material processing a practical addition to many curriculums.

Versatility for a Diverse Curriculum

The "muffle" itself—an interior chamber typically made of ceramic—isolates the workpiece from the heating elements. This prevents contamination and allows for processing in a controlled, protective atmosphere, a crucial concept in materials science.

With capabilities often reaching 1200°C to 1800°C, these furnaces support a wide variety of applications, from simple ashing in a chemistry lab to heat-treating metals or firing ceramics in an engineering course.

Understanding the Practical Considerations

While muffle furnaces are an excellent fit for education, selecting the right one involves understanding a few key trade-offs. The decision impacts not only the types of experiments you can run but also the long-term value of the investment.

The Critical Role of the Muffle

The muffle chamber is the defining feature. By separating the sample from direct contact with the heating elements, it ensures process purity. This is essential for teaching analytical techniques where sample integrity cannot be compromised.

Balancing Size and Capability

A smaller benchtop unit is cost-effective and space-efficient, ideal for introductory courses. However, larger floor models offer greater capacity and may come with more advanced programmable controls suitable for advanced research or senior-level projects.

Durability is Non-Negotiable

An educational furnace must be built to last. Look for models with extra sturdy construction and a reputation for using premium, reliable components. A furnace that can withstand frequent use (and occasional misuse) by students represents a much better long-term investment.

Making the Right Choice for Your Institution

Your selection should be guided by your specific curriculum, user base, and budget.

- If your primary focus is introductory chemistry or materials science: Prioritize a compact benchtop model with intuitive controls and robust safety features.

- If your primary focus is advanced engineering or graduate-level research: Invest in a furnace with fully programmable controls, a higher maximum temperature, and potentially options for atmosphere control.

- If your primary focus is maximizing a limited budget: Choose a model known for its durable construction and reliability, even if it means forgoing the most advanced digital features.

Ultimately, choosing the right muffle furnace is an investment in your students' ability to gain hands-on experience with fundamental thermal processing techniques safely and effectively.

Summary Table:

| Feature | Benefit for Education |

|---|---|

| Electric Operation | Eliminates open flames and fumes, enhancing safety for students |

| Advanced Temperature Control | Ensures repeatable experiments and teaches process control |

| Compact Benchtop Designs | Fits in small labs, cost-effective for tight budgets |

| Heat-Resistant Materials | Protects users from burns, durable for frequent use |

| Versatile Applications | Supports ashing, heat-treating, and ceramics across curricula |

Elevate your educational lab with KINTEK's advanced high-temperature furnace solutions! We specialize in providing safe, reliable, and customizable equipment like Muffle, Tube, and Rotary Furnaces, perfect for teaching and research. Our deep customization capabilities ensure we meet your unique curriculum needs. Contact us today to discuss how we can support your institution's goals with tailored solutions that enhance student learning and safety.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency