At its core, a digital interface transforms a muffle furnace from a simple high-temperature oven into a precision scientific instrument. It provides the ability to program, monitor, and execute complex heating protocols with an accuracy that analog controls cannot match, ensuring the reliability and repeatability of sensitive processes.

The digital interface is not merely a modern convenience; it is the control system that unlocks the full potential of the furnace. It ensures that the theoretical benefits of uniform heating and a controlled atmosphere are achieved reliably and repeatably in practice.

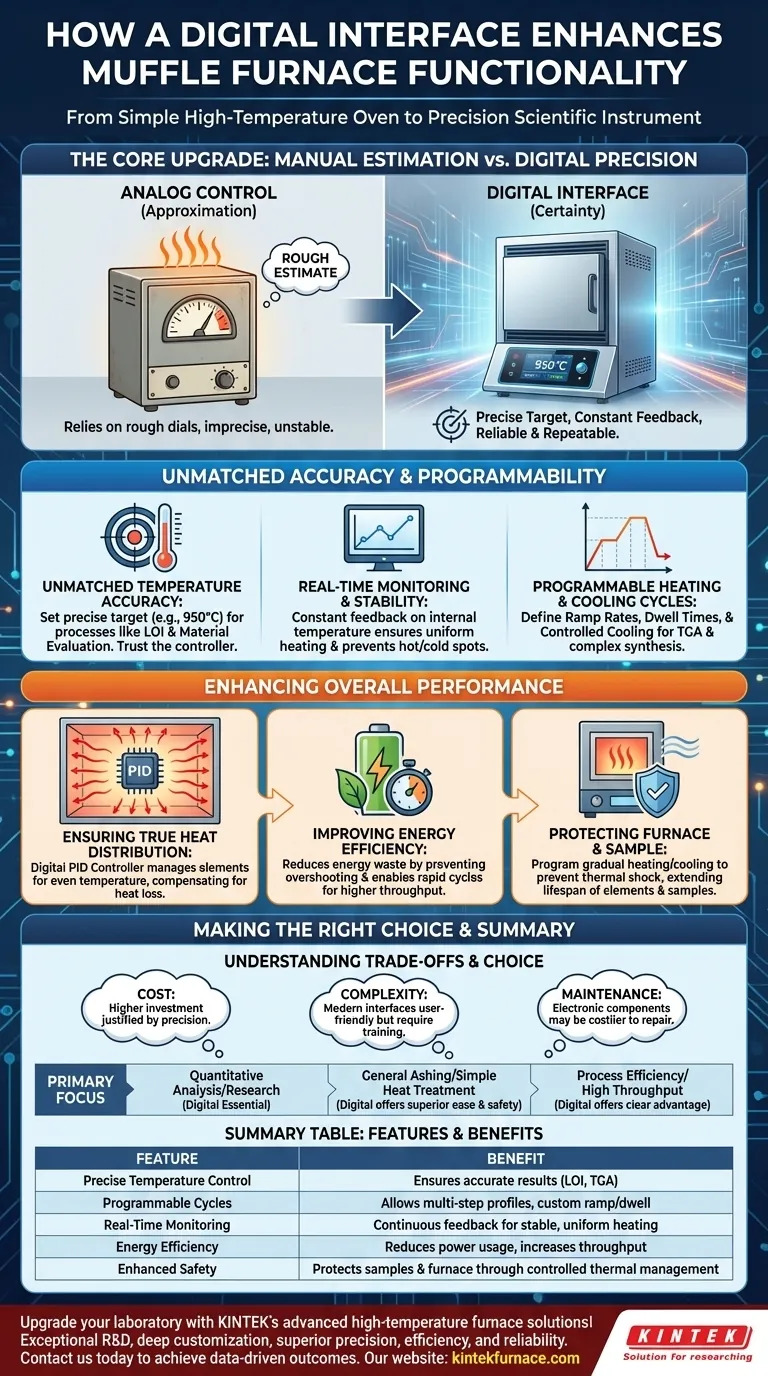

The Core Upgrade: From Manual Estimation to Digital Precision

The fundamental enhancement offered by a digital interface is the shift from approximation to certainty. This precision is the foundation for achieving valid results in demanding applications.

Unmatched Temperature Accuracy

An analog furnace relies on a dial that offers a rough temperature estimate. A digital furnace allows you to set a precise target, such as 950°C, and trust the controller to reach and maintain it.

This level of accuracy is non-negotiable for processes like loss on ignition (LOI) analysis or material property evaluation, where slight temperature deviations can render results invalid.

Real-Time Monitoring and Stability

A digital display provides constant, real-time feedback on the internal chamber temperature. This allows you to verify that the temperature is not just accurate but also stable throughout the process.

This continuous monitoring is critical for ensuring uniform heating, preventing hot or cold spots within the chamber that could compromise the sample.

Programmable Heating and Cooling Cycles

Modern digital controllers allow users to program multi-step heating profiles. You can define specific ramp rates (how quickly temperature rises), dwell times (how long it stays at a set temperature), and controlled cooling periods.

This capability is essential for advanced applications like thermogravimetric analysis (TGA), quenching, and complex material synthesis that require a precise thermal history.

How Digital Control Enhances Overall Performance

The precision of the digital interface has a cascading effect, improving the furnace's efficiency, safety, and the quality of the results it produces.

Ensuring True Heat Distribution

The muffle, or inner chamber, is physically designed to distribute heat evenly. However, it is the digital PID (Proportional-Integral-Derivative) controller that actively manages the heating elements to make this a reality.

By constantly adjusting power output based on real-time feedback, the controller compensates for heat loss and ensures the entire chamber maintains the target temperature with minimal fluctuation.

Improving Energy Efficiency

Digital furnaces are significantly more energy-efficient. By preventing temperature overshooting and executing cycles precisely, they use only the necessary amount of energy to complete a task.

Furthermore, their ability to perform rapid heating and cooling cycles means less time wasted and higher throughput, making them ideal for busy labs performing water quality or environmental analysis.

Protecting the Furnace and the Sample

Extreme temperature changes can cause thermal shock, damaging both the sample and the furnace's refractory materials.

A digital interface allows you to program gradual, controlled heating and cooling rates. This protects the integrity of the sample and extends the lifespan of the furnace's heating elements and internal chamber.

Understanding the Trade-offs

While immensely powerful, adopting a digital muffle furnace involves considerations that must be weighed against its benefits.

Cost and Justification

Digital muffle furnaces are typically more expensive than their analog counterparts. The initial investment must be justified by the need for the precision, repeatability, and programmability they offer.

Complexity and Training

A programmable digital interface is more complex than a simple knob. While modern interfaces are user-friendly, they still require a degree of training to use their advanced features effectively.

Maintenance and Repair

The electronic components of a digital controller, while reliable, can be more difficult and costly to repair than the simple mechanical parts of an analog system. This is a long-term operational consideration.

Making the Right Choice for Your Application

The decision to use a digital muffle furnace should be driven by the specific requirements of your work.

- If your primary focus is quantitative analysis or materials research: The precision, programmability, and data certainty of a digital furnace are essential.

- If your primary focus is general ashing or simple heat treatment: An analog furnace might be sufficient, but a digital model will still provide superior ease of use, repeatability, and safety.

- If your primary focus is process efficiency and high throughput: The rapid, automated cycles and energy savings of a modern digital furnace offer a clear operational advantage.

Ultimately, the digital interface elevates the muffle furnace from a heating device to a sophisticated tool for achieving reliable, data-driven outcomes.

Summary Table:

| Feature | Benefit |

|---|---|

| Precise Temperature Control | Ensures accurate results for sensitive analyses like LOI and TGA |

| Programmable Cycles | Allows multi-step heating profiles with custom ramp rates and dwell times |

| Real-Time Monitoring | Provides continuous feedback for stable, uniform heating |

| Energy Efficiency | Reduces power usage and increases throughput with optimized cycles |

| Enhanced Safety | Protects samples and furnace components through controlled thermal management |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior precision, efficiency, and reliability. Don't settle for less—contact us today to discuss how we can enhance your lab's performance and achieve data-driven outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production