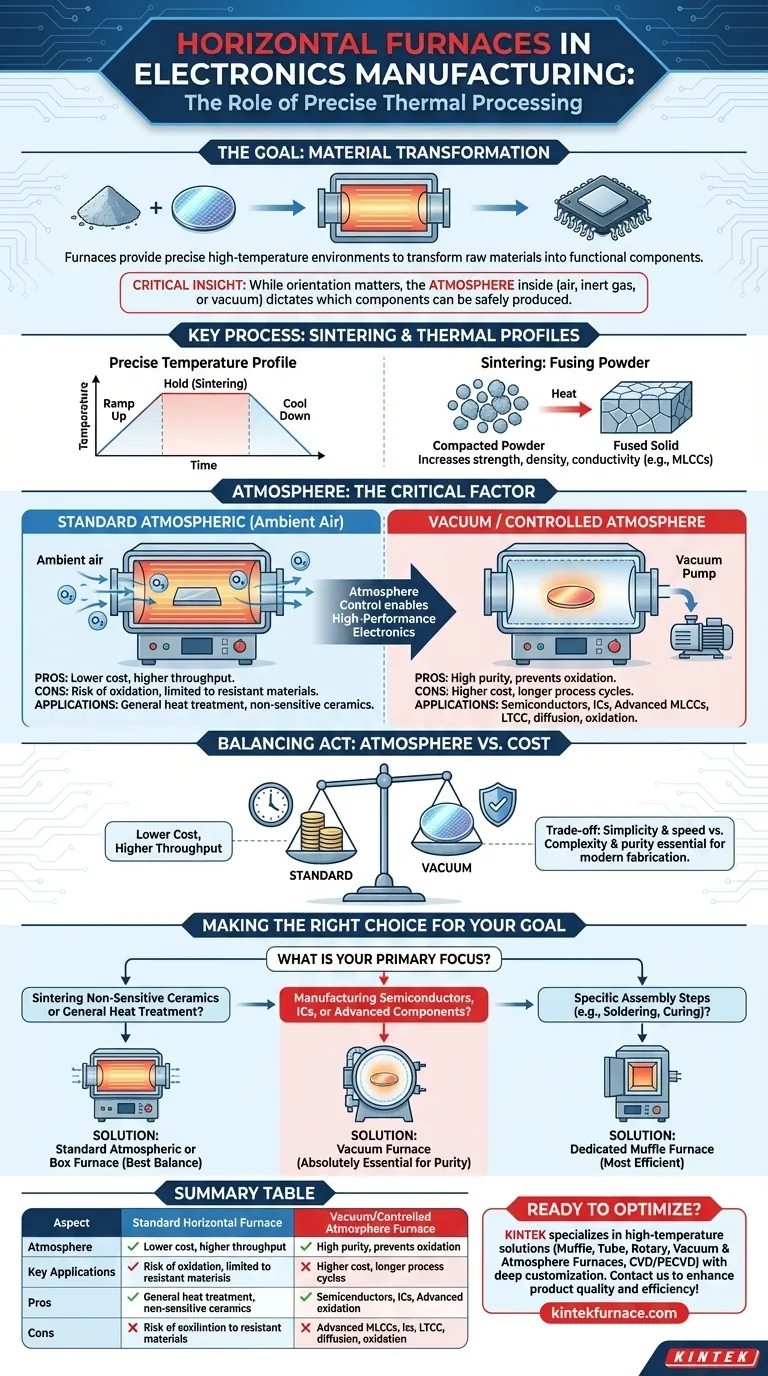

In short, horizontal furnaces are a specific type of thermal processing equipment used for critical manufacturing steps like sintering and thermal analysis of electronic components. They provide the precise, high-temperature environments needed to transform raw materials into functional parts with specific electrical and physical properties.

The term "horizontal furnace" describes the physical orientation of the heating chamber, but the most critical factor in electronics manufacturing is not the orientation, but the atmosphere inside—whether it's open air, an inert gas, or a vacuum. The choice of atmosphere dictates which electronic components can be safely and effectively produced.

The Foundation: Why Furnaces Are Essential in Electronics

At its core, manufacturing advanced electronics is a feat of material science. Furnaces provide the controlled thermal energy required to fundamentally alter materials and build them into complex devices.

The Goal: Precise Thermal Processing

Nearly every sophisticated electronic component, from a simple resistor to a complex integrated circuit, undergoes some form of heat treatment.

This isn't just about getting things hot. It's about executing a precise temperature profile—ramping up, holding at a specific temperature, and cooling down—to achieve a desired chemical or physical change in the material.

Key Process: Sintering

Many references point to sintering, a crucial furnace application. Sintering involves heating compacted powders (like ceramics or metals) to a temperature below their melting point.

This process causes the individual particles to fuse together, increasing the material's strength, density, and conductivity. This is fundamental for creating components like multi-layer ceramic capacitors (MLCCs) and other ceramic-based electronics.

Horizontal Furnaces vs. Other Process Environments

While a horizontal furnace is a common configuration, the choice of furnace is driven by the sensitivity of the process to atmospheric gases, especially oxygen.

The Standard Horizontal Furnace

A basic horizontal furnace often features a tube-shaped chamber that operates in ambient air. This setup is effective for processes and materials that are not sensitive to oxidation.

They are widely used for general thermal analysis and sintering of less reactive materials.

The Critical Need for Atmosphere Control: Vacuum Furnaces

For high-performance electronics, an uncontrolled atmosphere is the enemy. Oxygen and other reactive gases can create defects, contaminate materials, and ruin components.

This is where vacuum furnaces become essential. By removing the air from the chamber, these systems create a pristine environment. Many of these are built in a horizontal tube configuration.

They are non-negotiable for processes like semiconductor wafer diffusion and oxidation, integrated circuit packaging, and sintering advanced materials like LTCC (Low-Temperature Cofired Ceramics) and sensitive magnetic materials.

Other Specialized Furnaces

Other furnace types serve specific niches. Box furnaces are general-purpose workhorses for heat treatment and brazing, while muffle furnaces isolate the components from the heating elements, ideal for processes like soldering or curing epoxy.

Understanding the Trade-offs: Atmosphere vs. Cost

Choosing a furnace involves balancing the process requirements against operational complexity and cost. Understanding this trade-off is key to efficient manufacturing.

Standard Atmospheric Furnaces

Pro: These systems are generally simpler, less expensive to operate, and allow for higher throughput since no time is spent pumping down a vacuum.

Con: Their use is limited to materials and processes that are not harmed by exposure to oxygen and other gases at high temperatures.

Vacuum and Controlled Atmosphere Furnaces

Pro: They enable the creation of high-purity, high-performance components by preventing unwanted chemical reactions like oxidation. This is the only option for modern semiconductor fabrication.

Con: These furnaces are more complex, have a higher initial cost, and involve longer process cycles due to the need to create and break the vacuum.

Making the Right Choice for Your Goal

The right furnace is the one that meets the specific material and performance requirements of your component without adding unnecessary cost or complexity.

- If your primary focus is sintering non-sensitive ceramics or general heat treatment: A standard atmospheric horizontal or box furnace often provides the best balance of cost and capability.

- If your primary focus is manufacturing semiconductors, ICs, or advanced components (MLCC, LTCC): A vacuum furnace, often in a horizontal tube design, is absolutely essential to ensure material purity and device performance.

- If your primary focus is specific assembly steps like soldering or curing: A dedicated muffle furnace may be the most efficient tool for the job.

Ultimately, selecting the correct thermal processing equipment is a foundational decision that directly impacts product quality, reliability, and manufacturing yield.

Summary Table:

| Aspect | Standard Horizontal Furnace | Vacuum/Controlled Atmosphere Furnace |

|---|---|---|

| Atmosphere | Ambient air | Inert gas or vacuum |

| Key Applications | Sintering non-sensitive ceramics, general heat treatment | Semiconductor fabrication, advanced MLCCs, LTCC |

| Pros | Lower cost, higher throughput | High purity, prevents oxidation |

| Cons | Limited to oxidation-resistant materials | Higher cost, longer process cycles |

Ready to optimize your electronics manufacturing with the right furnace? KINTEK specializes in high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization to meet your unique needs. Contact us today to discuss how our expertise can enhance your product quality and efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing