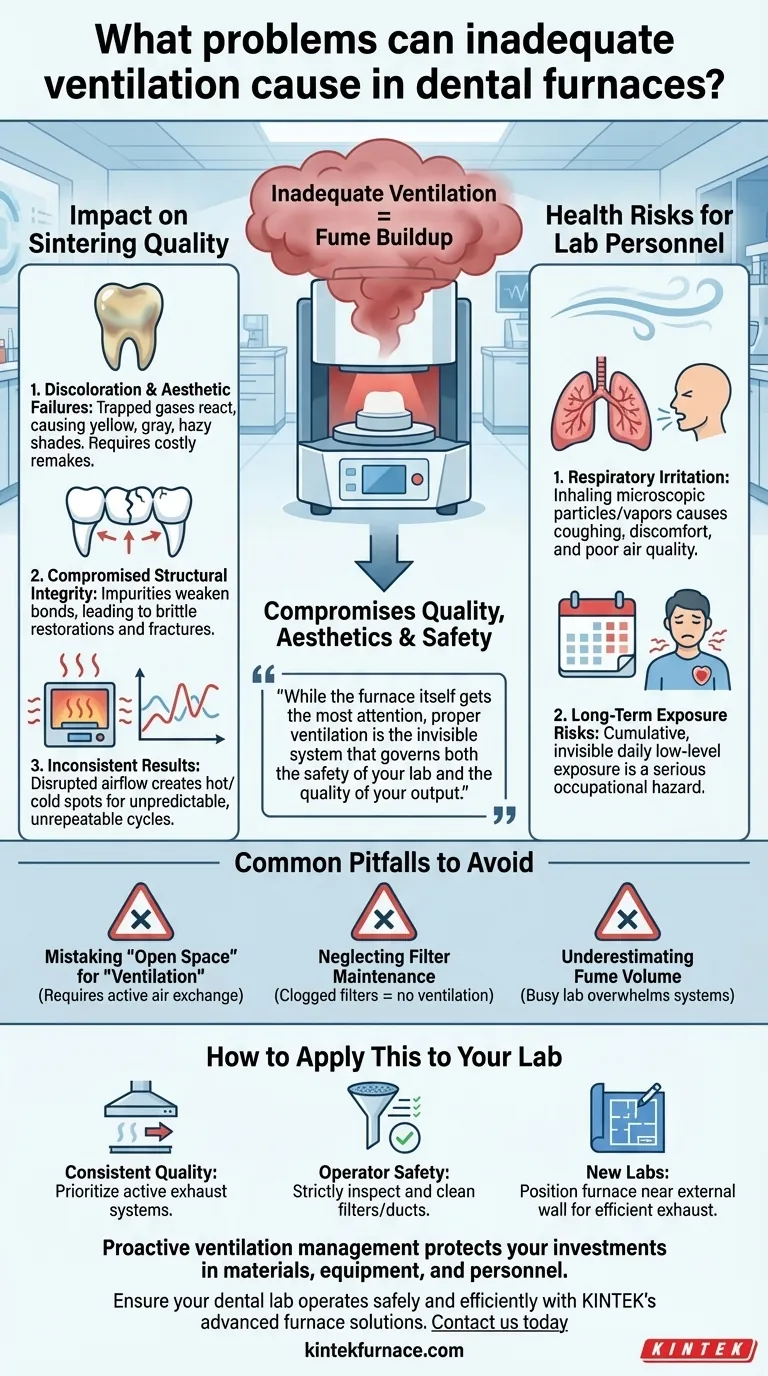

Inadequate ventilation for a dental furnace leads to a buildup of fumes generated during the sintering process. This contamination directly compromises the quality and aesthetics of your restorations and, more importantly, creates significant health and safety risks for laboratory personnel.

While the furnace itself gets the most attention, proper ventilation is the invisible system that governs both the safety of your lab and the quality of your output. Failing to manage airflow effectively introduces contaminants that can ruin your work and harm your team.

The Impact on Sintering Quality

When fumes cannot escape, they remain inside the furnace chamber. These trapped gases and microscopic particles are contaminants that directly interfere with the highly sensitive sintering process.

Discoloration and Aesthetic Failures

Trapped gases can chemically react with the surface of zirconia or other ceramic materials. This often results in a noticeable yellow, gray, or hazy discoloration, ruining the intended shade and requiring a costly remake.

Compromised Structural Integrity

The sintering process works by fusing material particles together at a crystalline level. Fumes introduce impurities that can get trapped between these particles, preventing a complete and uniform bond. This leads to a weaker final restoration that is more brittle and prone to fracture under occlusal load.

Inconsistent Results

Poor ventilation doesn't just trap fumes; it also disrupts stable airflow and heat distribution within the furnace. This can create hot and cold spots, leading to inconsistent sintering from one cycle to the next, making it impossible to achieve predictable, repeatable results.

The Health Risks for Lab Personnel

The byproducts of sintering are not meant to be inhaled. A buildup of these fumes turns the lab environment into a hazardous workspace.

Respiratory Irritation

Sintering fumes can contain microscopic particulate matter and chemical vapors. Inhaling these substances can irritate the eyes, nose, throat, and lungs, leading to coughing, discomfort, and a general decline in air quality.

Long-Term Exposure Risks

Daily, low-level exposure to chemical byproducts is a serious occupational hazard. Over time, this can contribute to chronic respiratory conditions and other long-term health issues. The danger is often invisible and cumulative.

Common Pitfalls to Avoid

Achieving proper ventilation is often misunderstood. Simply having a furnace in a large room is not sufficient.

Mistaking "Open Space" for "Ventilation"

A large room can still have stagnant air. Effective ventilation requires active air exchange—a mechanism to pull contaminated air out and bring fresh air in. Passive measures are rarely enough.

Neglecting Filter Maintenance

Many ventilation systems use filters. If these filters become clogged with dust and debris, they severely restrict airflow, rendering the system useless. A clogged filter is just as bad as having no ventilation at all.

Underestimating Fume Volume

A single sintering cycle might not seem to produce many fumes, but a busy lab running multiple cycles a day can quickly overwhelm an inadequate ventilation system. The total volume of contaminants must be factored into your ventilation strategy.

How to Apply This to Your Lab

Your approach to ventilation should be a formal part of your lab's operational and safety protocol.

- If your primary focus is consistent, high-quality restorations: Prioritize an active exhaust system that pulls fumes directly away from the furnace chamber to prevent any risk of contamination.

- If your primary focus is operator safety and compliance: Implement and document a strict schedule for inspecting and cleaning all ventilation filters and ducts.

- If you are setting up a new lab or furnace: Position the furnace near an external wall from the outset to create the shortest, most efficient path for an exhaust system.

Proactive ventilation management is the most effective way to protect your investments in materials, equipment, and personnel.

Summary Table:

| Problem Type | Key Issues |

|---|---|

| Quality Impact | Discoloration, weakened restorations, inconsistent sintering |

| Health Risks | Respiratory irritation, long-term exposure hazards |

| Common Pitfalls | Inadequate air exchange, clogged filters, underestimating fume volume |

Ensure your dental lab operates safely and efficiently with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to protect your restorations and personnel!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations