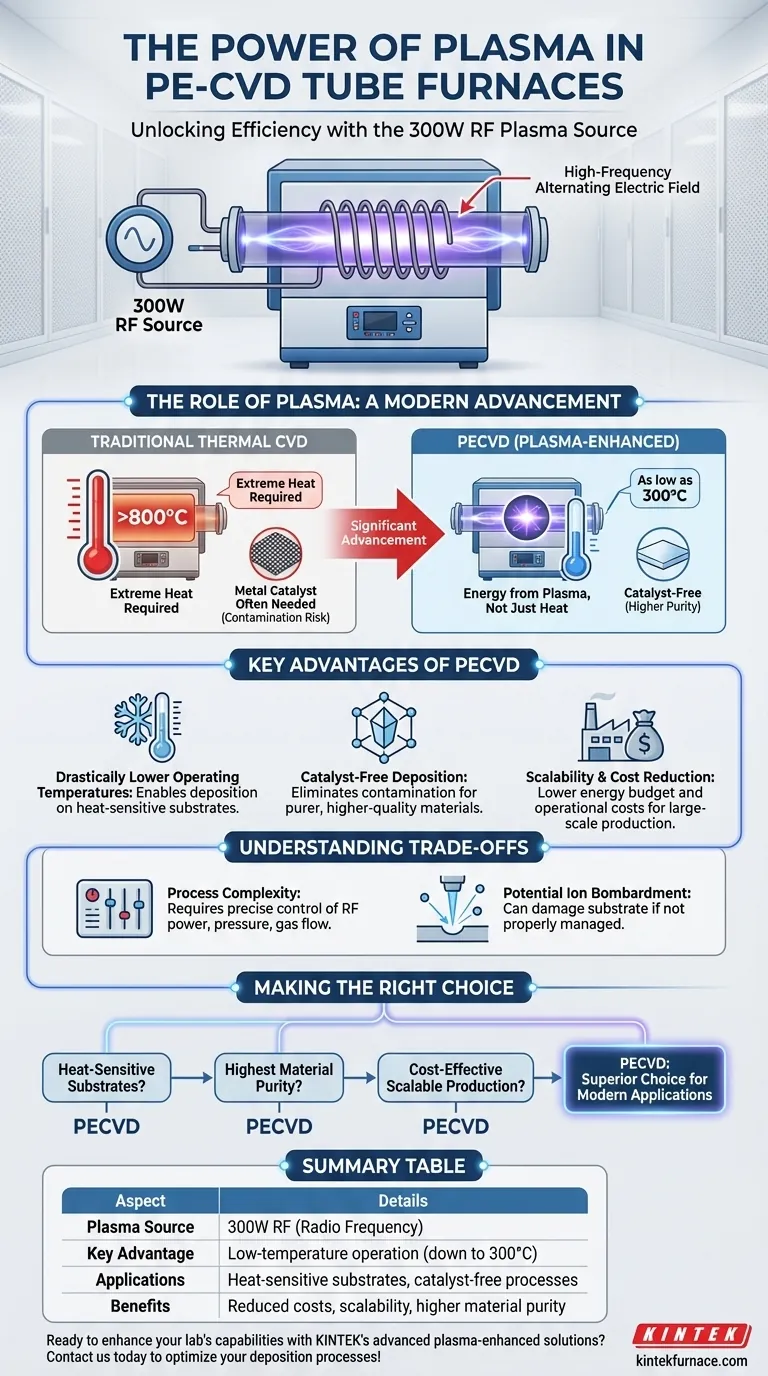

The definitive answer is that PE-CVD tube furnaces utilize a 300W RF (Radio Frequency) plasma source. This source is what enables the "plasma-enhanced" aspect of the chemical vapor deposition process, generating the necessary energy to deposit materials at significantly lower temperatures than traditional methods.

While the specific hardware is a 300W RF source, the real innovation is using plasma to overcome the high-temperature limitations of conventional chemical vapor deposition (CVD). This makes the entire process more efficient, cost-effective, and versatile.

The Role of Plasma in Modern CVD

Plasma-Enhanced Chemical Vapor Deposition (PECVD) represents a significant advancement over traditional thermal CVD. The core difference lies in how energy is supplied to the precursor gases.

What is Plasma?

Plasma is often called the fourth state of matter. It's an ionized gas containing a mix of ions, electrons, and neutral particles.

In the context of PECVD, this electrically charged gas provides the energy needed to break down precursor molecules, a task that would otherwise require extreme heat.

How the RF Source Creates Plasma

The 300W RF source generates a high-frequency alternating electric field inside the furnace tube.

This field rapidly accelerates free electrons, causing them to collide with gas molecules. These collisions transfer energy, stripping electrons from the molecules and creating the reactive ions and radicals that define the plasma.

Key Advantages of a Plasma-Enhanced Process

The introduction of a plasma source fundamentally changes the deposition process, offering clear benefits over older techniques.

Drastically Lower Operating Temperatures

Traditional CVD relies on thermal energy, often requiring temperatures above 800°C to break down precursor gases. PECVD, by using plasma, can achieve the same results at much lower temperatures, sometimes as low as 300°C.

This lower temperature threshold is crucial for depositing materials onto sensitive substrates that cannot withstand high heat.

Catalyst-Free Deposition

Many traditional CVD processes require a metal catalyst to facilitate material growth. These catalysts can introduce contamination into the final product.

PECVD's highly reactive plasma environment often eliminates the need for a catalyst, leading to the in-situ preparation of purer, higher-quality materials.

Scalability and Cost Reduction

Lowering the energy budget by reducing heating requirements directly translates to lower operational costs.

This efficiency, combined with the ability to deposit on a wider range of substrates, makes PECVD a more scalable and economically viable solution for large-scale production of advanced materials like 2D graphene or silicon nitride films.

Understanding the Trade-offs

While PECVD is highly advantageous, it's important to recognize its unique challenges.

Process Complexity

Introducing a plasma source adds variables that must be precisely controlled, such as RF power, pressure, and gas flow rates. Optimizing these parameters can be more complex than in a simple thermal CVD setup.

Potential for Ion Bombardment

The high-energy ions within the plasma can bombard the substrate surface during deposition. While sometimes beneficial for film density, this can also cause damage or introduce stress into the deposited layer if not properly managed.

Making the Right Choice for Your Goal

Selecting the right deposition method depends entirely on your material and substrate requirements.

- If your primary focus is depositing on heat-sensitive substrates: PECVD is the superior choice, as its low-temperature process prevents substrate damage.

- If your primary focus is achieving the highest possible material purity: PECVD's catalyst-free nature offers a significant advantage by eliminating a common source of contamination.

- If your primary focus is cost-effective, scalable production: The reduced energy consumption and operational efficiency of PECVD make it a more economical option for industrial applications.

Ultimately, leveraging a plasma source allows you to achieve high-quality material deposition under conditions that are simply not possible with conventional thermal methods.

Summary Table:

| Aspect | Details |

|---|---|

| Plasma Source | 300W RF (Radio Frequency) |

| Key Advantage | Low-temperature operation (down to 300°C) |

| Applications | Deposition on heat-sensitive substrates, catalyst-free processes |

| Benefits | Reduced costs, scalability, higher material purity |

Ready to enhance your lab's capabilities with advanced plasma-enhanced solutions? KINTEK specializes in high-temperature furnace systems, including PE-CVD tube furnaces with customizable RF plasma sources. Our expertise in R&D and in-house manufacturing ensures tailored solutions for diverse laboratory needs, from Muffle and Tube Furnaces to Vacuum & Atmosphere Systems. Contact us today to discuss how we can optimize your deposition processes for efficiency and precision!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- What are the main advantages of PECVD tube furnaces compared to CVD tube furnaces? Lower Temp, Faster Deposition, and More

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs