Beyond the world of semiconductors, Chemical Vapor Deposition (CVD) furnaces are indispensable tools across a surprisingly diverse range of specialized fields. Their use extends to aerospace for creating durable components, advanced optics for manufacturing high-performance lenses and displays, the energy sector for producing solar cells, and cutting-edge material science for synthesizing materials like graphene.

The versatility of CVD furnaces is not about the furnace itself, but about the fundamental process it enables. CVD allows for the atomic-level construction of ultra-pure, thin-film materials, making it a platform technology for enhancing or creating entirely new material properties on almost any substrate.

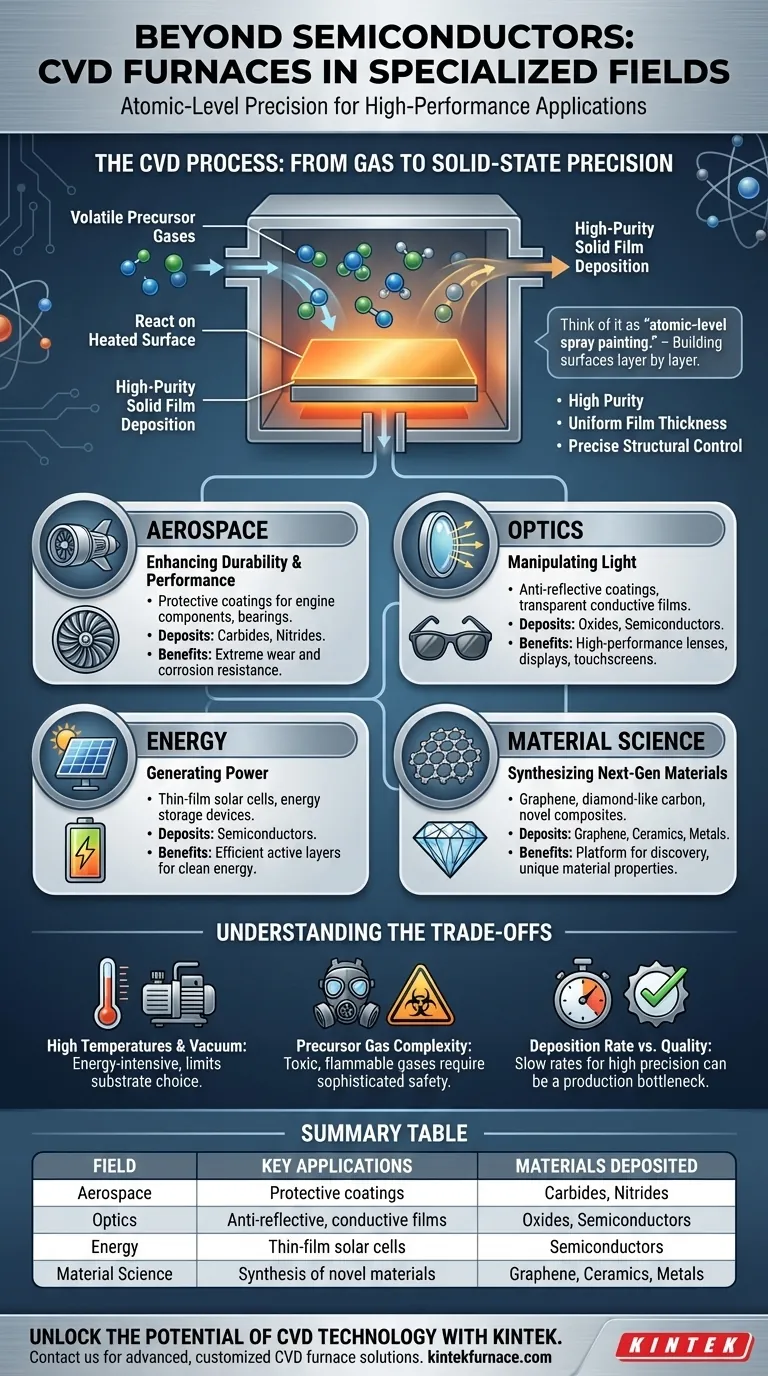

The Foundation: From Gas to Solid-State Precision

Understanding why CVD is so widely adopted requires looking at the core process. It is less about heating and more about controlled, constructive chemistry.

What is Chemical Vapor Deposition?

At its heart, CVD is a process where volatile precursor gases react or decompose on a heated surface (the substrate) inside the furnace chamber. This chemical reaction results in the deposition of a high-purity solid material as a thin film or coating on that substrate.

Think of it as a form of "atomic-level spray painting." Instead of paint droplets, you are using carefully chosen gases that build a new, solid surface layer by layer with exceptional precision.

Why CVD is a Platform Technology

The value of CVD comes from its unique capabilities. It allows engineers and scientists to create materials that are often impossible to produce with traditional melt-and-cast methods.

Key advantages include high purity, uniform film thickness even over complex shapes, and precise control over the material's structure and properties. This control is what makes it a foundational technology for so many different goals.

Core Applications Beyond Microchips

While integral to the semiconductor industry, the ability to engineer surfaces gives CVD furnaces a critical role in many other high-tech sectors.

Enhancing Durability and Performance

Many industries rely on CVD to make parts stronger, last longer, and resist harsh environments. This is a primary application in manufacturing and aerospace.

These applications often involve depositing extremely hard materials like carbides and nitrides. This creates protective coatings on cutting tools, engine components, and bearings, dramatically improving their wear and corrosion resistance.

Manipulating Light and Energy

CVD is essential for fabricating devices that interact with light and generate energy. This includes everything from sunglasses to solar panels and advanced displays.

By depositing specific oxides or other semiconductor materials, manufacturers can create anti-reflective coatings, transparent conductive films for touchscreens and OLEDs, or the critical active layers in thin-film solar cells.

Synthesizing Next-Generation Materials

For material scientists, CVD furnaces are laboratories for discovery. They are the primary tool for producing many of the most promising advanced materials.

This includes synthesizing two-dimensional materials like graphene sheets for electronics and filtration, growing films of diamond-like carbon for low-friction coatings, and forming novel ceramic or metal composites through powder metallurgy techniques.

Understanding the Trade-offs

Despite its versatility, CVD is not a universal solution. Its power comes with specific operational requirements and limitations that are important to understand.

High Temperatures and Vacuum

Most CVD processes require very high temperatures and a controlled vacuum or low-pressure environment. This makes the equipment energy-intensive and limits the types of substrate materials that can be used without being damaged by the heat.

Precursor Gas Complexity

The process relies on precursor gases that can be highly toxic, flammable, or corrosive. This necessitates sophisticated safety protocols, gas handling systems, and exhaust management, adding to the operational complexity and cost.

Deposition Rate vs. Quality

Achieving the highest quality, purest, and most uniform films often requires a very slow deposition rate. While ideal for precision applications, this can make CVD a bottleneck for high-volume, low-cost manufacturing compared to other coating methods.

Making the Right Choice for Your Goal

The relevance of CVD depends entirely on the problem you are trying to solve. Its value is in creating high-performance surfaces, not bulk material.

- If your primary focus is mechanical engineering or manufacturing: View CVD as a critical tool for creating high-performance surfaces that resist wear, friction, and corrosion.

- If your primary focus is on electronics or photonics: Understand CVD as the foundational process for building the active layers in semiconductor devices, solar cells, and displays.

- If your primary focus is on material science or R&D: Recognize CVD as a versatile synthesis platform for creating novel materials and composites that are impossible to produce otherwise.

Ultimately, a CVD furnace is a tool for transforming common materials into high-performance products by precisely engineering their surfaces at the atomic level.

Summary Table:

| Field | Key Applications | Materials Deposited |

|---|---|---|

| Aerospace | Protective coatings for engine components, bearings | Carbides, nitrides |

| Optics | Anti-reflective coatings, transparent conductive films | Oxides, semiconductors |

| Energy | Thin-film solar cells, energy devices | Semiconductors |

| Material Science | Synthesis of graphene, diamond-like carbon, composites | Graphene, ceramics, metals |

Unlock the potential of CVD technology for your lab! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your research with tailored CVD furnace solutions!

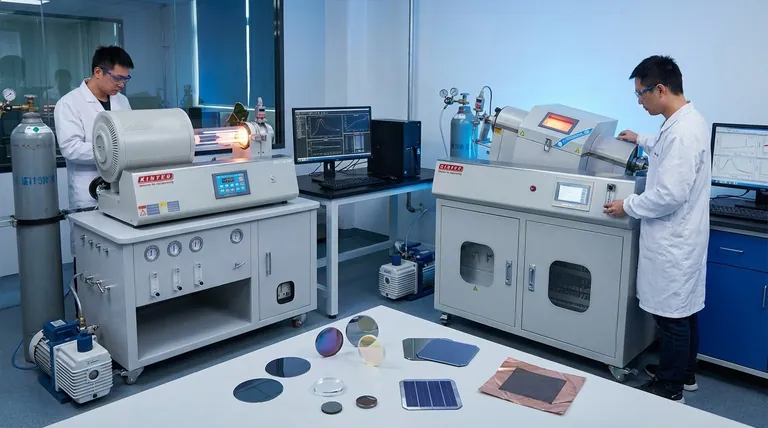

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the role of temperature in PECVD? Optimize Film Quality and Substrate Protection

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- What are gas barrier films, and how is PECVD involved in their creation? Discover Advanced Packaging Solutions