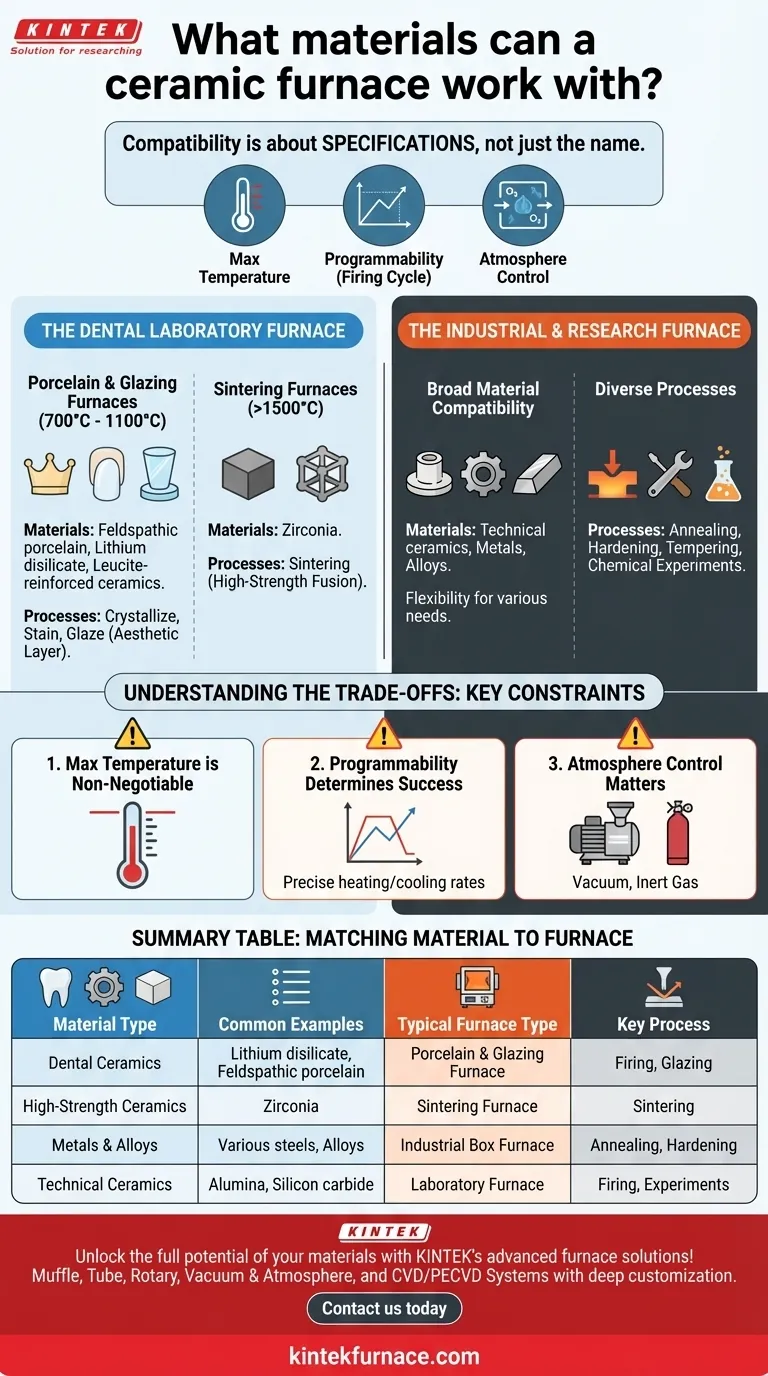

At its core, a "ceramic furnace" is a broad term for a high-temperature oven, and the specific materials it can process depend entirely on its design and capabilities. While many are specialized for dental materials like lithium disilicate, feldspathic porcelain, and zirconia, other industrial versions can handle a wider range of materials including general ceramics, metals, and alloys.

The most critical takeaway is that the material compatibility of a furnace is not about its name, but its technical specifications. The key factors are the furnace's maximum temperature, its programming capabilities, and its ability to control the internal atmosphere.

The Two Worlds of Ceramic Furnaces

The term "ceramic furnace" is most commonly used in two distinct fields: dentistry and general industry. While they both use heat to transform materials, their capabilities and intended uses are fundamentally different.

The Dental Laboratory Furnace

These furnaces are precision instruments designed for the specific needs of creating dental restorations. They are not a one-size-fits-all tool; they are typically specialized for one of two primary tasks.

-

Porcelain & Glazing Furnaces: These are built for firing materials like feldspathic porcelain, lithium disilicate, and leucite-reinforced ceramics. Their job is to crystallize, stain, and glaze these materials, often at temperatures between 700°C and 1100°C. They excel at creating the final aesthetic layer of a crown or veneer.

-

Sintering Furnaces: These are high-temperature workhorses designed for materials like zirconia. Sintering is a process that fuses powdered material into a solid, dense object, requiring much higher temperatures—often exceeding 1500°C. A standard porcelain furnace cannot perform this task.

The Industrial & Research Furnace

Often called a box furnace or laboratory furnace, this type is a versatile tool used in materials science, metallurgy, and electronics.

-

Broad Material Compatibility: These furnaces are designed for flexibility. They can be used to fire a wide variety of technical ceramics, metals, and alloys.

-

Diverse Processes: Their application goes beyond simple firing. They are used for processes like annealing (softening metal), hardening, tempering, and conducting chemical experiments at high temperatures.

Understanding the Trade-offs: Key Technical Constraints

The material a furnace can handle is dictated by its engineering. Understanding these limitations is crucial to avoid damaging the material or the furnace itself.

Maximum Temperature is Non-Negotiable

This is the most important specification. A furnace designed for low-fusing porcelain simply lacks the heating elements and insulation required to reach the sintering temperatures of zirconia. Attempting to push a furnace beyond its rated maximum is a recipe for failure.

Programmability Determines a Material's Success

Every ceramic material has a unique and precise firing cycle—a recipe of heating rates, hold times, and cooling rates. A furnace must have a programmable controller sophisticated enough to execute these specific cycles flawlessly to achieve the desired strength and aesthetics.

Atmosphere Control Matters

Some advanced processes require a specific atmosphere inside the heating chamber. Many dental porcelain furnaces use a vacuum to remove impurities and increase density. Industrial furnaces might introduce inert gases to prevent oxidation when heat-treating certain metals. A simple furnace with no atmosphere control limits the types of processes you can run.

Making the Right Choice for Your Goal

To select the correct equipment, you must first define your material and your desired outcome.

- If your primary focus is creating aesthetic crowns and veneers: You need a dedicated dental porcelain furnace compatible with materials like lithium disilicate and feldspathic ceramics.

- If your primary focus is fabricating high-strength zirconia frameworks: You must use a high-temperature sintering furnace capable of reaching temperatures of 1500°C or higher.

- If your primary focus is materials research or multi-purpose industrial heating: A versatile laboratory box furnace provides the widest range of temperature capabilities and material options, including ceramics, metals, and alloys.

Ultimately, successful material processing depends on precisely matching the furnace's capabilities to the specific requirements of your material.

Summary Table:

| Material Type | Common Examples | Typical Furnace Type | Key Process |

|---|---|---|---|

| Dental Ceramics | Lithium disilicate, Feldspathic porcelain | Porcelain & Glazing Furnace | Firing, Glazing |

| High-Strength Ceramics | Zirconia | Sintering Furnace | Sintering |

| Metals & Alloys | Various steels, Alloys | Industrial Box Furnace | Annealing, Hardening |

| Technical Ceramics | Alumina, Silicon carbide | Laboratory Furnace | Firing, Experiments |

Unlock the full potential of your materials with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how we can enhance your processes and deliver reliable, tailored results for your specific applications!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision