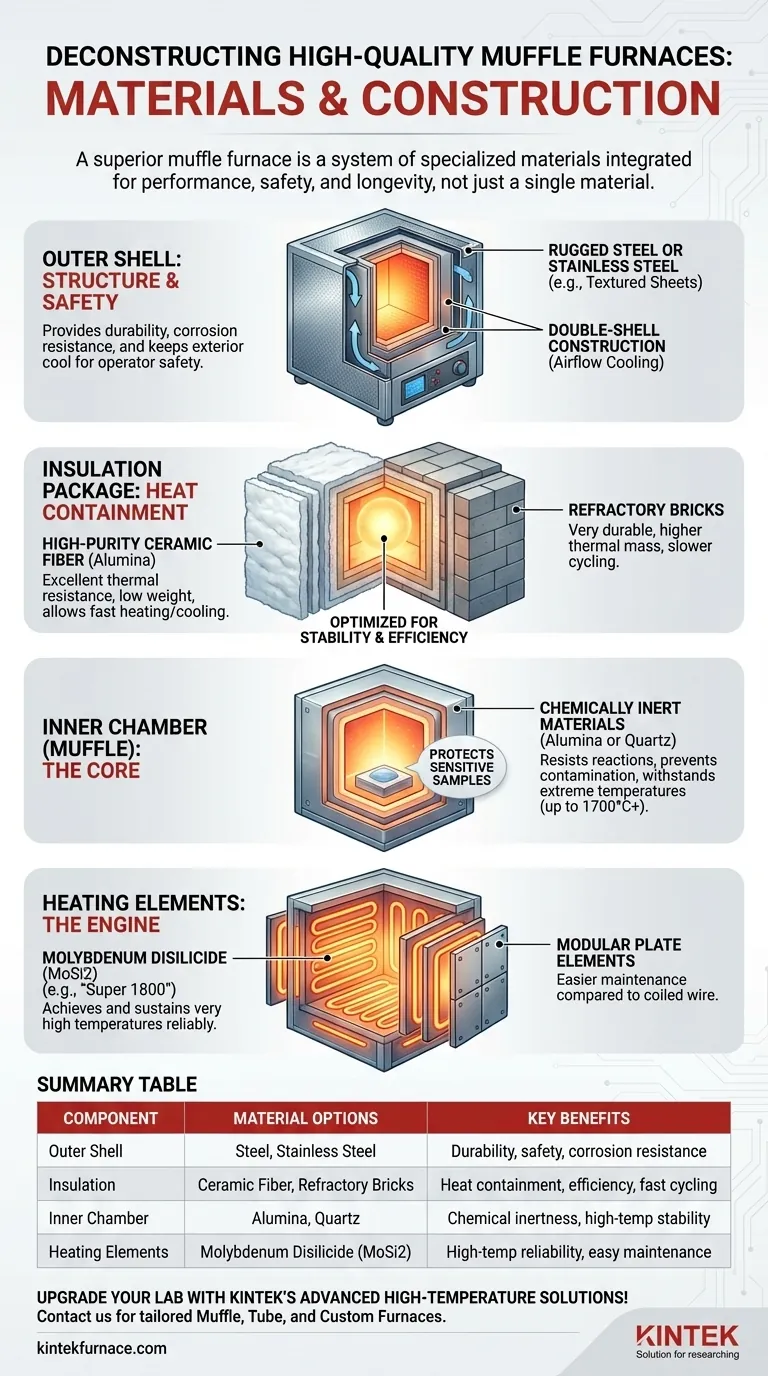

In short, a high-quality muffle furnace is constructed from a system of specialized materials. This includes a rugged steel or stainless steel outer shell for durability, a multi-layered insulation package using high-purity ceramic fibers, a chemically inert inner chamber made of alumina or quartz, and high-performance heating elements like molybdenum disilicide to achieve and sustain extreme temperatures.

A superior muffle furnace is not defined by a single material, but by the strategic integration of several. Each component—from the outer shell to the inner chamber—uses a material specifically chosen for its ability to provide structural support, contain intense heat, or resist chemical reactions, ensuring performance, safety, and longevity.

Deconstructing the Muffle Furnace: A Component Guide

To understand what makes a furnace "high-quality," we must look at its construction as a system. Each part has a distinct role, and the material used is critical to its function.

The Outer Shell: Structural Integrity and Safety

The external casing provides the furnace's structure and protects both the user and the internal components.

High-quality furnaces use a rugged steel shell, often constructed from welded angle steel and heavy-gauge steel plates. Some premium models feature textured stainless steel sheets for enhanced durability and corrosion resistance.

A key feature of top-tier furnaces is double-shell construction. This design allows for airflow between the inner and outer walls, keeping the exterior surface temperature low. This improves operator safety and extends the life of electronic components.

The Insulation Package: Containing the Heat

The primary job of insulation is to keep heat inside the chamber, ensuring temperature stability and energy efficiency.

The most common and effective material is high-purity alumina fiber insulation. This is a type of ceramic fiber known for its excellent thermal resistance and low weight. It allows the furnace to heat and cool relatively quickly.

In some designs, especially older or more robust industrial models, refractory bricks are used. While very durable, they are heavier and have higher thermal mass, leading to slower heating and cooling cycles. A "graded" insulation package in a premium furnace might use multiple types of insulation in layers to optimize performance.

The Inner Chamber (Muffle): The Heart of the Furnace

The muffle is the sealed inner chamber that holds the sample. Its material is critical because it is exposed to the highest temperatures and must not react with the material being heated.

The best materials for this purpose are high-purity alumina and quartz. Both offer exceptional high-temperature stability (up to 1700°C or more) and are chemically inert, preventing contamination of sensitive samples.

These ceramic muffles are chosen for their ability to maintain structural integrity even under severe thermal stress, ensuring a clean and controlled environment for experiments.

The Heating Elements: The Engine of the System

Heating elements are responsible for generating the furnace's extreme temperatures. Their quality dictates the maximum achievable temperature and the furnace's lifespan.

Top-tier furnaces use advanced elements like molybdenum disilicide (MoSi2), often marketed under names like "Super 1800." These are capable of reaching and sustaining very high temperatures reliably.

For ease of maintenance, premium models often feature modular plate heating elements, which can be replaced more easily than coiled wire elements embedded in the insulation.

Understanding the Trade-offs

The choice of materials involves balancing performance, cost, and operational needs. Understanding these trade-offs is key to identifying a furnace that truly fits your requirements.

Insulation: Ceramic Fiber vs. Refractory Brick

Ceramic fiber insulation is lightweight and has low thermal conductivity, allowing for faster heat-up and cool-down times. This makes it ideal for lab environments where cycles are run frequently.

Refractory bricks are denser and more durable, offering excellent longevity but at the cost of much slower thermal cycling. They are often found in heavy-duty industrial applications where the furnace may run continuously for long periods.

Construction: Single-Shell vs. Double-Shell

A single-shell furnace is simpler and less expensive to manufacture. However, its exterior surface can become extremely hot, posing a safety risk and potentially damaging nearby equipment.

A double-shell design actively cools the exterior, making it safe to touch. This is a hallmark of a higher-quality, safer furnace designed with the operator in mind.

Making the Right Choice for Your Goal

Your specific application will determine which material features are most important.

- If your primary focus is maximum temperature and chemical purity: Prioritize a furnace with a high-purity alumina or quartz muffle and molybdenum disilicide (MoSi2) heating elements.

- If your primary focus is rapid cycling and efficiency: Choose a model with lightweight ceramic fiber insulation over one with heavy refractory bricks.

- If your primary focus is operator safety and long-term durability: Insist on a double-shell steel construction and features like independent over-temperature controllers.

Ultimately, the quality of a muffle furnace lies in how its materials work together to create a safe, stable, and precise high-temperature environment.

Summary Table:

| Component | Material Options | Key Benefits |

|---|---|---|

| Outer Shell | Steel, Stainless Steel | Durability, corrosion resistance, safety |

| Insulation | Ceramic Fiber, Refractory Bricks | Heat containment, energy efficiency, fast cycling |

| Inner Chamber | Alumina, Quartz | Chemical inertness, high-temperature stability |

| Heating Elements | Molybdenum Disilicide (MoSi2) | High-temperature reliability, easy maintenance |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced performance and safety. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production