In short, retort furnaces are utilized for any high-temperature material process that requires a precisely controlled atmosphere. Their primary applications include the heat treatment of sensitive metals like titanium and stainless steel, the sintering of advanced ceramics and powdered metals, and specialized chemical reactions such as calcination.

The core challenge in many high-temperature processes isn't just the heat, but preventing the material from reacting with the surrounding air. Retort furnaces solve this by using a sealed vessel—the retort—to isolate the material, enabling processing in a vacuum or a specific gas environment free from oxygen and other contaminants.

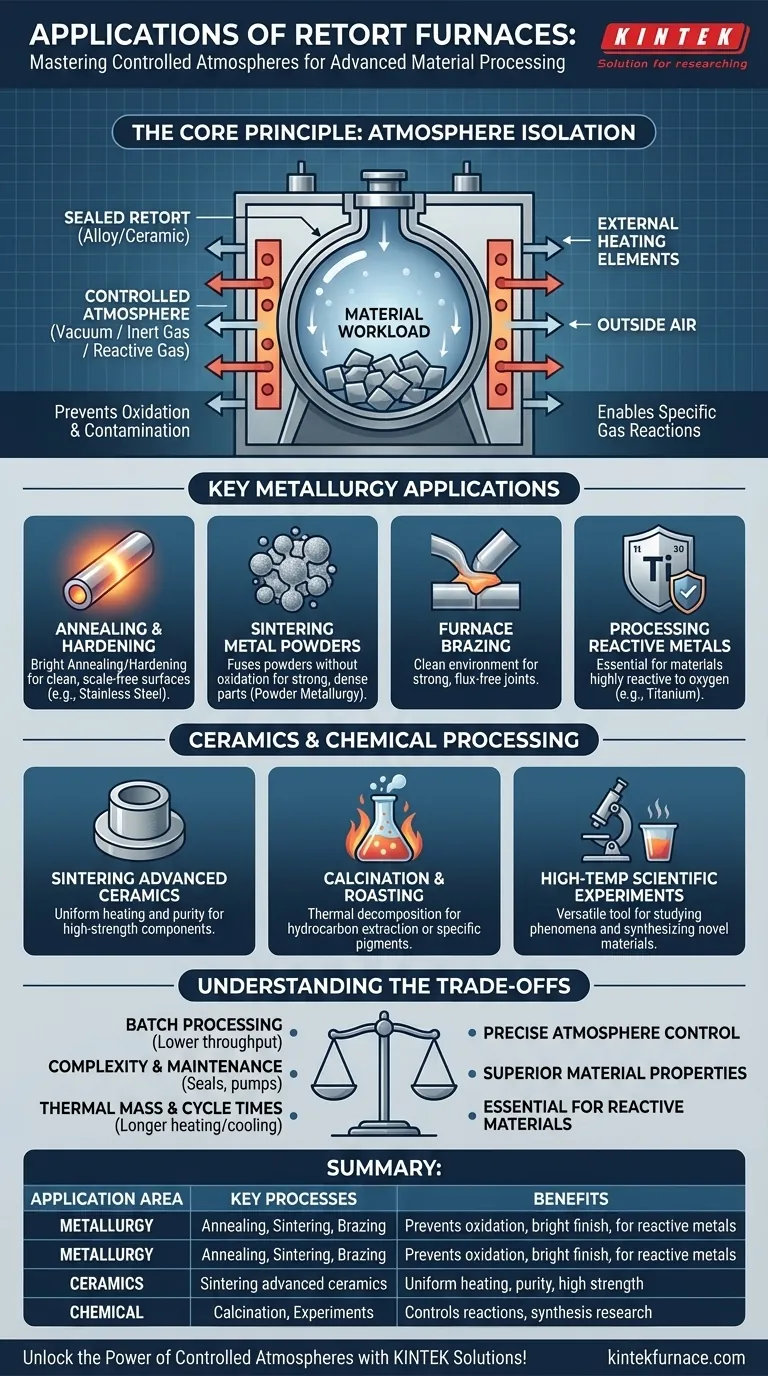

The Core Principle: Isolating the Atmosphere

A retort furnace's unique capability comes from the retort itself, which is a sealed, heat-resistant container typically made of alloy or ceramic that holds the workload. This design separates the material from the furnace's heating elements and the outside air.

Preventing Oxidation and Contamination

At high temperatures, many materials readily oxidize or react with contaminants in the air. This can ruin the material's surface finish, structural integrity, or chemical properties.

The retort allows for the air to be pumped out to create a vacuum or be replaced with an inert gas like argon or nitrogen. This controlled atmosphere is the single most important feature of a retort furnace.

Enabling Specific Gas Reactions

In some applications, a specific reactive gas is intentionally introduced into the retort. For example, a carburizing atmosphere can be used to harden the surface of steel parts. The sealed retort ensures these reactions happen uniformly and without unwanted side effects.

Key Applications in Metallurgy

The metallurgical industry relies heavily on retort furnaces to achieve specific material properties that are impossible in an open-air furnace.

Annealing and Hardening

Annealing (softening), hardening, and other heat treatments are performed in a retort to produce a clean, scale-free surface. This is often called bright annealing or bright hardening, a critical process for stainless steel and other alloys where appearance and purity are paramount.

Sintering Metal Powders

Sintering is the process of fusing metal powders together using heat, just below their melting point. Performing this in a retort prevents the fine powders from oxidizing and ensures strong, dense parts are formed, a cornerstone of the powder metallurgy field.

Furnace Brazing

Brazing joins two metal components using a filler metal with a lower melting point. A retort furnace provides a clean, controlled environment that allows the filler metal to flow freely and create a strong, unblemished joint without the need for flux.

Processing Reactive Metals

Metals like titanium are highly reactive with oxygen, especially at elevated temperatures. A retort furnace is not just beneficial but essential for processing these materials, as any exposure to air would compromise their integrity.

Applications in Ceramics and Chemical Processing

The need for atmospheric control extends beyond metals into the production of advanced materials and chemical synthesis.

Sintering Advanced Ceramics

Similar to metals, ceramic powders are sintered to create dense, high-strength components. A retort furnace ensures uniform heating and a pure atmosphere, which is critical for producing advanced ceramics used in electronics and high-wear applications.

Calcination and Roasting

Calcination is a thermal decomposition process. Retort furnaces are used to heat materials like oil shale to extract hydrocarbons or to produce highly specific pigments and catalysts by carefully controlling the chemical reactions that occur.

High-Temperature Scientific Experiments

For materials scientists and chemists, the retort furnace is an indispensable research tool. It provides a versatile, contained environment to study high-temperature phenomena, synthesize novel materials, and analyze chemical reactions with precision.

Understanding the Trade-offs

While powerful, retort furnaces are not the solution for every heating application. Understanding their limitations is key to making an informed decision.

Batch Processing Limitations

By their nature, retort furnaces are batch-processing systems. The retort must be loaded, sealed, purged, heated, cooled, and unloaded for each cycle. This results in lower throughput compared to continuous belt furnaces.

Complexity and Maintenance

The seals, vacuum pumps, and gas management systems that enable atmosphere control add complexity. These components require regular maintenance to prevent leaks and ensure process repeatability.

Thermal Mass and Cycle Times

The retort itself must be heated along with the workload, increasing the furnace's overall thermal mass. This can lead to longer heating and cooling cycles compared to a furnace without an internal muffle.

Making the Right Choice for Your Process

Your choice of thermal processing equipment should be dictated by the specific requirements of your material and production goals.

- If your primary focus is high-purity metal treatment: A retort furnace is ideal for achieving a bright, oxide-free finish in processes like annealing, brazing, or hardening.

- If your primary focus is processing reactive materials: For metals like titanium or certain advanced ceramics, the atmospheric control of a retort furnace is non-negotiable.

- If your primary focus is high-volume production of non-reactive materials: A continuous, open-air furnace is likely a more efficient and cost-effective solution.

- If your primary focus is research and development: The versatility and precise environmental control of a retort furnace make it an invaluable tool for experimentation.

Ultimately, understanding the critical role of the atmosphere in your process is the key to selecting the right technology for the task.

Summary Table:

| Application Area | Key Processes | Benefits |

|---|---|---|

| Metallurgy | Annealing, hardening, sintering, brazing | Prevents oxidation, enables bright finishing, essential for reactive metals like titanium |

| Ceramics | Sintering advanced ceramics | Ensures uniform heating and purity for high-strength components |

| Chemical Processing | Calcination, roasting, scientific experiments | Controls chemical reactions, supports material synthesis and research |

Unlock the Power of Controlled Atmospheres for Your Lab!

At KINTEK, we specialize in delivering advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure our retort furnaces precisely meet your experimental requirements, whether you're working with sensitive metals, advanced ceramics, or complex chemical processes.

Don't let atmospheric challenges hold you back—contact us today to discuss how our solutions can enhance your material processing efficiency and results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality