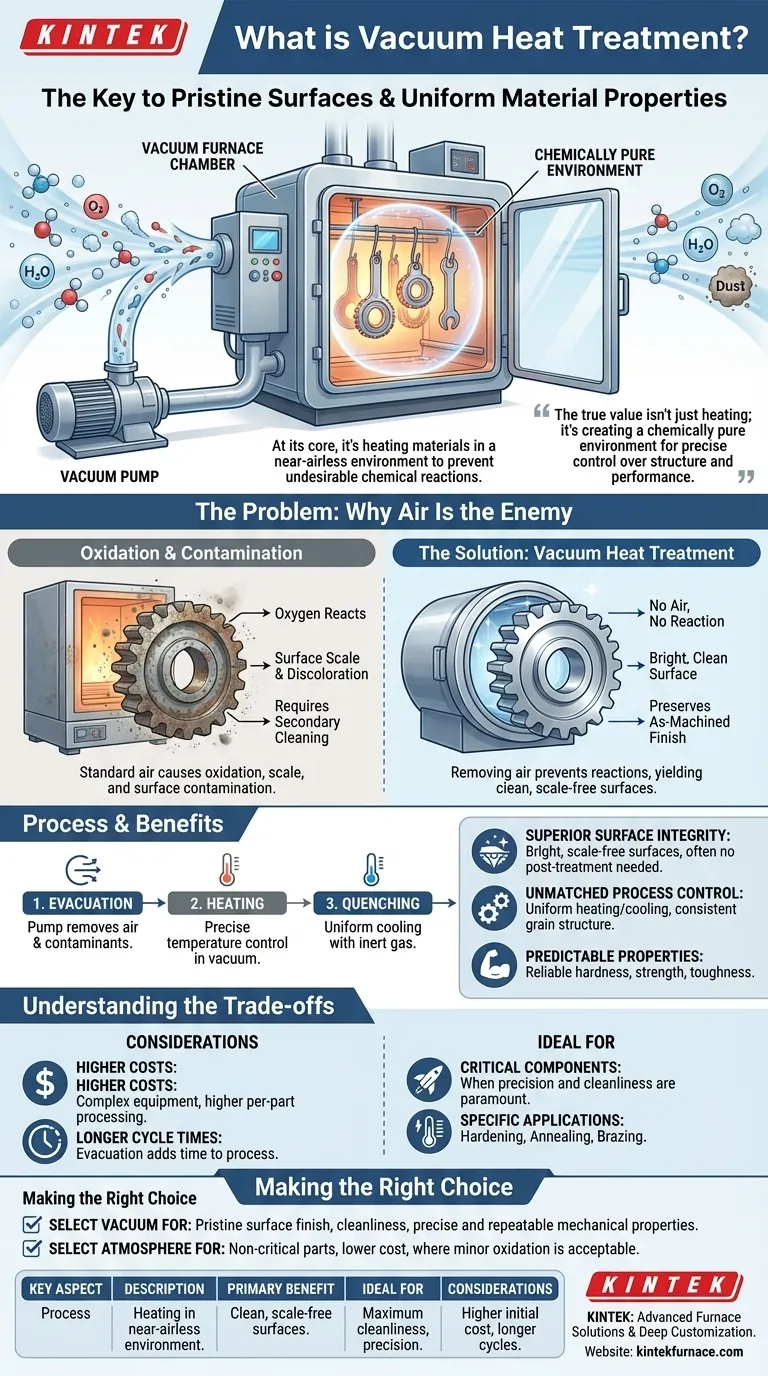

At its core, vacuum heat treatment is a highly controlled process where materials are heated within a furnace that has had the air removed. By creating a vacuum, this method fundamentally prevents the undesirable chemical reactions, such as oxidation, that occur when metals are heated in a normal atmosphere. This results in components with a clean, bright surface and exceptionally uniform material properties.

The true value of vacuum heat treatment isn't just about heating metal; it's about creating a chemically pure environment. This eliminates surface contamination and gives engineers precise control over a material's final structure and performance, something traditional methods cannot guarantee.

The Problem: Why Air Is the Enemy of Heat Treatment

To understand the value of a vacuum, you must first understand the problems caused by a normal atmosphere during heating.

The Issue of Oxidation

When metals are heated in the presence of oxygen, they oxidize. This creates a layer of scale or discoloration on the surface.

This oxidation layer must often be removed through secondary processes like sandblasting or chemical cleaning, adding time and cost while potentially affecting the part's final dimensions.

The Challenge of Contamination

Standard air isn't just oxygen and nitrogen. It contains water vapor, dust, and other contaminants.

At high temperatures, these elements can react with the material's surface, leading to unpredictable changes in its chemistry and mechanical properties.

How Vacuum Heat Treatment Provides the Solution

By removing the air from the furnace chamber, the vacuum process directly addresses the root causes of these issues.

The Principle: Removing the Atmosphere

A vacuum pump evacuates the sealed furnace, reducing the internal pressure to a near-perfect vacuum.

This removes the reactive elements—primarily oxygen and water vapor—that would otherwise compromise the material's surface and integrity.

The Process: From Evacuation to Quenching

First, the material is loaded into the sealed chamber. The system is then pumped down to the required vacuum level, removing contaminants in the process.

The material is heated to a precise temperature, held for a specified duration, and then cooled (quenched) in a highly controlled manner, often using an inert gas like nitrogen or argon. This ensures uniform cooling and predictable results.

The Result: Superior Surface Integrity

Because there is no oxygen to react with, parts emerge from the furnace with a bright, clean, and scale-free surface.

This often eliminates the need for post-treatment cleaning, preserving the component's as-machined finish and dimensional accuracy.

The Benefit: Unmatched Process Control

Vacuum furnaces allow for extremely uniform heating and cooling. This precise thermal management results in a more consistent grain structure throughout the material.

The outcome is a component with more reliable and repeatable mechanical properties, such as hardness, strength, and toughness.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not a universal solution. It involves specific considerations.

Higher Initial and Operational Costs

Vacuum furnaces and their associated pumping systems are more complex and expensive than conventional atmosphere furnaces. This can translate to a higher per-part processing cost.

Potentially Longer Cycle Times

The step of evacuating the furnace to a deep vacuum level adds time to the overall process cycle compared to simply heating a part in an atmosphere furnace.

Process Suitability

While excellent for many applications like hardening, annealing, and brazing, some surface treatments may be more efficiently or effectively performed using controlled gas atmospheres rather than a deep vacuum.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on your project's specific requirements for performance, finish, and cost.

- If your primary focus is a pristine surface finish and cleanliness: Vacuum treatment is the superior choice, as it prevents oxidation and often eliminates the need for secondary cleaning operations.

- If your primary focus is achieving precise and repeatable mechanical properties: The uniform heating and controlled quenching offered by a vacuum furnace deliver unparalleled consistency for critical components.

- If your primary focus is cost minimization for non-critical parts: Traditional atmosphere-based heat treatment may be a more economical option if minor surface oxidation and variability are acceptable.

Ultimately, choosing vacuum heat treatment is an investment in quality control, ensuring your materials achieve their maximum potential performance and integrity.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Heating materials in a near-airless environment to prevent chemical reactions. |

| Primary Benefit | Clean, scale-free surfaces and highly uniform material properties. |

| Ideal For | Applications requiring maximum cleanliness, precision, and repeatable performance. |

| Considerations | Higher initial cost and longer cycle times compared to atmosphere furnaces. |

Ready to unlock the full potential of your materials with precision vacuum heat treatment?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact us today using the form below to discuss how our vacuum furnace technology can bring superior quality control, eliminate secondary cleaning, and ensure your components achieve their maximum performance and integrity.

[Get in Touch - #ContactForm]

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today