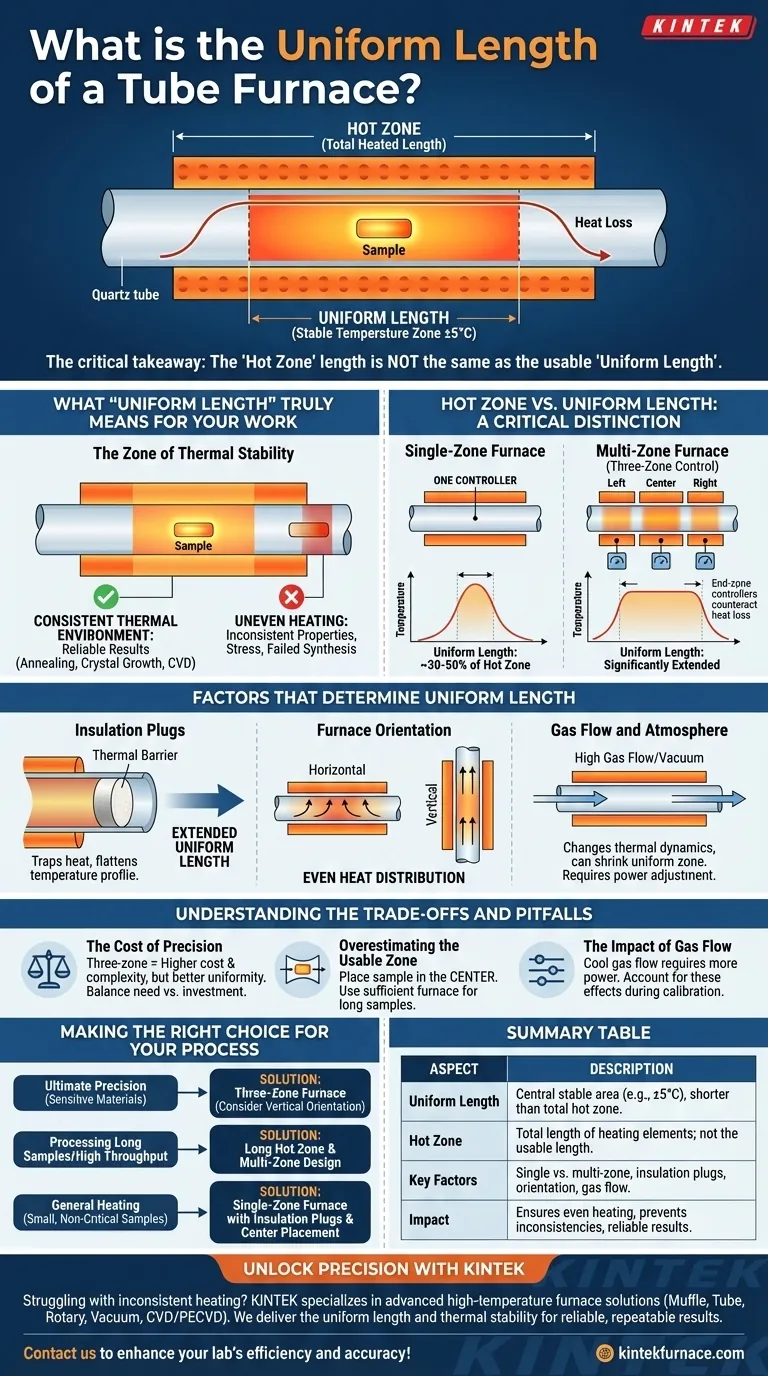

In a tube furnace, the uniform length is the central portion of the heated chamber where the temperature is stable and consistent, typically within a specified tolerance like ±5°C. While standard furnaces may have a total heated "hot zone" of 300mm or 600mm, the effective uniform length is always shorter than this total, as temperature naturally drops off near the ends of the tube.

The critical takeaway is that the "hot zone" length listed on a spec sheet is not the same as the usable "uniform length." Understanding and maximizing this uniform length is the key to achieving reliable and repeatable results in any thermal process.

What "Uniform Length" Truly Means for Your Work

To achieve a successful outcome, whether you are annealing a metal, growing a crystal, or performing chemical vapor deposition (CVD), your sample must experience a consistent thermal environment. The uniform length defines this trustworthy processing area.

The Zone of Thermal Stability

The uniform length is the region where the temperature profile is flat. Outside of this zone, toward the ends of the furnace tube, significant heat loss occurs, causing the temperature to drop sharply.

Placing a sample outside this stable zone will result in uneven heating, leading to inconsistent material properties, internal stresses, or failed synthesis.

Hot Zone vs. Uniform Length: A Critical Distinction

Manufacturers specify a hot zone length, which describes the total length of the heating elements. A furnace with a 600mm hot zone does not provide 600mm of uniform temperature.

The uniform length is a percentage of the hot zone. For a basic single-zone furnace, the uniform length might only be the central 30-50% of the hot zone.

Why It's Crucial for Thermally Sensitive Processes

Processes involving thermally sensitive parts or requiring precise phase transitions depend entirely on temperature accuracy. The outstanding uniformity of a properly configured tube furnace ensures every part of your sample receives the exact same thermal treatment, guaranteeing predictable and high-quality results.

Factors That Determine Uniform Length

The effective length of the uniform zone is not a fixed number. It is a dynamic characteristic influenced by the furnace's design and how you operate it.

Single-Zone vs. Multi-Zone Control

A single-zone furnace uses one controller for the entire heating element. This design is simple and cost-effective but inherently produces a temperature drop-off at the ends.

A multi-zone furnace (typically three zones) has independent controllers for the center and two end zones. The end-zone controllers can be set to a higher temperature to actively inject more heat, counteracting the natural heat loss and dramatically extending the uniform temperature zone across a much larger portion of the tube.

The Role of Insulation Plugs

Placing ceramic fiber insulation plugs at the ends of the process tube is one of the most effective ways to improve uniformity. These plugs act as thermal barriers, trapping heat and minimizing losses to the ambient environment. This simple addition helps flatten the temperature profile and extend the uniform length.

Furnace Orientation: Horizontal vs. Vertical

Horizontal furnaces can sometimes experience slight temperature variations due to natural convection currents, where hot air rises and creates a gradient from the top to the bottom of the tube.

Vertical furnaces can offer superior uniformity because convection currents align with the tube axis, promoting more even heat distribution along the sample's length.

Understanding the Trade-offs and Pitfalls

Achieving perfect uniformity requires balancing cost, complexity, and operational reality.

The Cost of Precision

A three-zone furnace provides far greater uniformity but is more expensive and complex to program than a single-zone furnace. You must decide if the precision required by your process justifies the added investment.

Overestimating the Usable Zone

A common mistake is assuming the entire hot zone is usable. Always place your sample directly in the center of the furnace. If you are processing a long sample, you must use a furnace with a hot zone and uniform length sufficient to cover its entire length.

The Impact of Gas Flow and Atmosphere

Running a process with high gas flow or under a vacuum changes the thermal dynamics inside the tube. A constant flow of cool gas will require more power to maintain temperature and can shrink the uniform zone. These effects must be accounted for during process calibration.

Making the Right Choice for Your Process

Your ideal furnace setup depends entirely on the sensitivity and scale of your application.

- If your primary focus is ultimate precision for sensitive materials: A three-zone furnace is essential for maximizing the uniform length and ensuring precise control. Consider a vertical orientation.

- If your primary focus is processing long samples or maximizing throughput: Select a furnace with a long hot zone (e.g., 600mm or more) and ensure it is a multi-zone design to maintain uniformity across the length.

- If your primary focus is general heating of small, non-critical samples: A cost-effective single-zone furnace is often sufficient. Always use insulation plugs and place your sample in the exact center to achieve the best possible consistency.

By moving beyond the spec sheet and understanding the factors that create thermal uniformity, you gain direct control over the quality and repeatability of your results.

Summary Table:

| Aspect | Description |

|---|---|

| Uniform Length | Central heated area with stable temperature (e.g., ±5°C tolerance), shorter than total hot zone. |

| Hot Zone | Total length of heating elements; not the same as uniform length. |

| Key Factors | Single-zone vs. multi-zone control, insulation plugs, furnace orientation (horizontal/vertical). |

| Impact on Processes | Ensures even heating for annealing, CVD, crystal growth; prevents inconsistencies and failures. |

Unlock Precision in Your Thermal Processes with KINTEK

Struggling with inconsistent heating in your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure your furnace delivers the uniform length and thermal stability required for reliable, repeatable results in sensitive applications like material annealing and chemical synthesis.

Don't let temperature variations compromise your work—contact us today to discuss how our solutions can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab