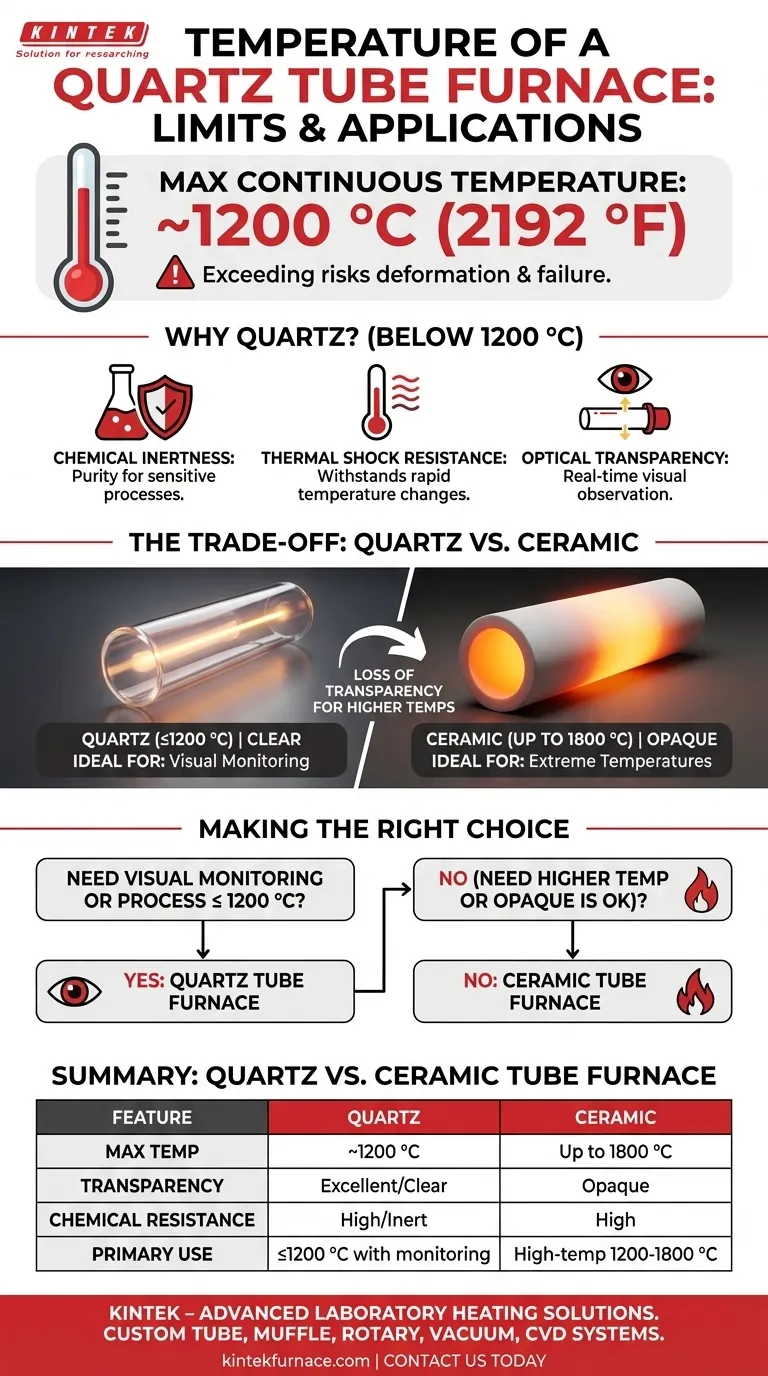

The operating temperature of a quartz tube furnace is fundamentally limited by the material properties of the quartz tube itself. While the furnace's heating elements may be capable of higher heat, the practical and safe maximum temperature for continuous use is approximately 1200 °C (2192 °F). Exceeding this temperature risks deforming the tube, compromising its structural integrity and the process environment within.

A quartz tube furnace offers a unique combination of features: high temperature capability up to 1200 °C, excellent chemical resistance, and optical transparency. However, its primary limitation is this temperature ceiling, which is lower than that of furnaces using ceramic tubes.

The Role of Quartz in High-Temperature Applications

A tube furnace is designed to provide a controlled, high-temperature environment. The choice of tube material is one of the most critical design decisions, directly impacting the furnace's performance and suitable applications.

The 1200 °C Temperature Ceiling

The 1200 °C limit is not arbitrary; it is rooted in the physics of quartz (fused silica). As quartz approaches this temperature, it begins to soften.

Operating above this point can cause the tube to sag or deform, especially if under vacuum, which can lead to catastrophic failure. For this reason, 1200 °C is considered the maximum reliable operating temperature.

Why Quartz is a Preferred Material

Despite its temperature limit, quartz is widely used for several compelling reasons that make it ideal for many research and industrial processes.

Chemical Inertness: Quartz is highly unreactive and will not contaminate most materials being processed, ensuring the purity of the sample or reaction.

Thermal Shock Resistance: It can withstand rapid changes in temperature better than many other ceramics, which is valuable when processes require quick heating or cooling cycles.

Optical Transparency: This is the most distinct advantage of quartz. It allows for direct, real-time visual observation of the process inside the furnace, which is invaluable for research and development.

Understanding the Trade-offs: Quartz vs. Ceramic

The 1200 °C limit of quartz creates a clear decision point. When higher temperatures are required, an alternative material must be used.

When You Need to Exceed 1200 °C

For processes that require temperatures between 1200 °C and 1800 °C, furnaces must use a ceramic tube, most commonly made of high-purity alumina.

These materials have a much higher melting point and remain rigid at temperatures that would cause a quartz tube to fail.

The Inevitable Sacrifice: Transparency

The primary trade-off for achieving higher temperatures is the loss of visual access. Ceramic tubes like alumina are opaque.

This forces a choice: prioritize seeing your process with quartz or achieving extreme temperatures with ceramic.

Uniform Heating and Control

Regardless of the tube material, high-temperature tube furnaces are designed for excellent temperature uniformity along the heated zone.

Precise digital controllers allow for accurate and repeatable thermal profiles, which is essential for sensitive processes in materials science and chemistry.

Making the Right Choice for Your Application

Selecting the correct furnace configuration depends entirely on the temperature and observation requirements of your specific process.

- If your primary focus is a process at or below 1200 °C, especially if visual monitoring is beneficial: A quartz tube furnace is the ideal choice for its clarity and chemical purity.

- If your primary focus is achieving the highest possible temperatures (up to 1800 °C): You must select a furnace equipped with a ceramic (alumina) tube and forgo the ability to observe the process directly.

Choosing the right tube material is the critical first step toward a successful and safe high-temperature experiment.

Summary Table:

| Feature | Quartz Tube Furnace | Ceramic Tube Furnace |

|---|---|---|

| Max Temperature | ~1200 °C (2192 °F) | Up to 1800 °C |

| Transparency | Excellent (Optically Clear) | Opaque |

| Chemical Resistance | High (Inert) | High |

| Primary Use Case | Processes ≤1200 °C with visual monitoring | High-temperature processes (1200-1800 °C) |

Need a high-temperature furnace tailored to your exact needs? KINTEK specializes in advanced laboratory heating solutions. Leveraging exceptional R&D and in-house manufacturing, we provide a diverse range of furnaces—including precise Tube Furnaces with quartz or ceramic options, Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today (#ContactForm) to enhance your lab's capabilities with reliable, high-performance equipment!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency